Cone vacuum pump of advantages

At present, there are two kinds of vacuum pumps in thermal power plants, one is the plane type water ring vacuum pump, the other is the cone type water ring vacuum pump. In these two kinds of vacuum pumps, the plane type vacuum pump is the first generation of water ring vacuum pump, the cone type vacuum pump is the second generation of water ring vacuum pump developed on the basis of the plane pump, in the structure and performance, the cone pump has obvious advantages over the plane pump.

I. Cone vacuum pump structural improvement

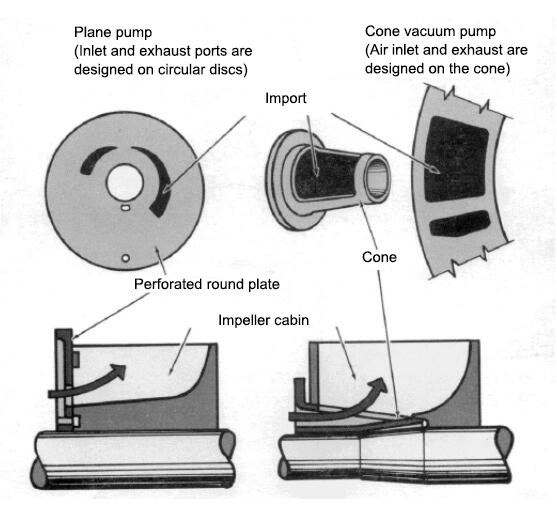

1. Improvement of inlet and exhaust ports

The inlet and outlet of the plane pump open at the end of the impeller, which is restricted by the formation of the water ring and the upward eccentricity of the impeller. And cone pump cone opening deep into the impeller chamber, its opening geometric size is larger.

Figure 1: Opening of cone pump

2. Change the single-stage pump to two-stage pump: the compression ratio of single-stage pump is about 30:1, while the compression ratio of each stage of the two-stage pump is 6:1 and 5:1, respectively.

3. Add condensing nozzle to the vacuum pump inlet pipe

Cone pump because the inlet opening is much larger than the plane vacuum pump inlet opening, so in the inlet air entrapped water into the vacuum pump body and less impact on the efficiency of the vacuum pump, so the cone pump can be in the inlet pipe with a condensing nozzle.

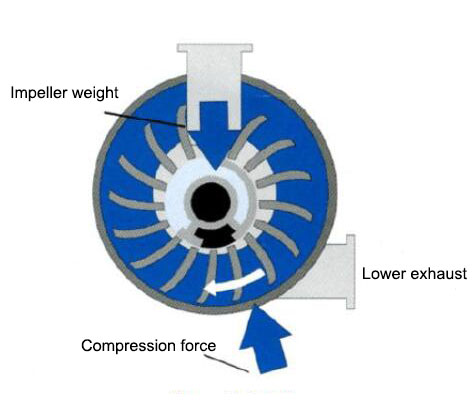

4. Improvement of eccentricity position

The impeller of the plane vacuum pump is inclined to the upper end of the shell, the exhaust port is in the upper part of the vacuum pump body, the impeller of the cone pump is inclined to the lower part of the shell, the exhaust port is in the lower part of the vacuum pump body.

Figure 2: Off-center position

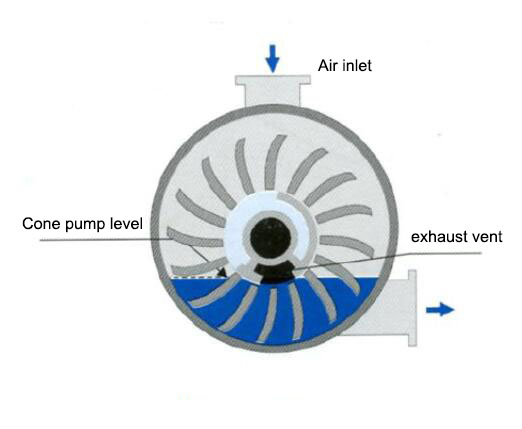

Ii. Cone vacuum pump advantages in performance

1. High efficiency

First of all, the cone pump intake area is large, the opening into the impeller chamber, the channel is the most smooth, the intake resistance is small, greatly improve the pump pumping capacity. Secondly, in the vacuum pump inlet pipe with condensation water to condense condensable gas, the volume of gas suction vacuum pump will be greatly reduced, further improve the pump pumping capacity. In addition, after using two-stage pump, the compression ratio is reduced and the compression heat is also reduced, and the compression heat is transferred to the sealing water twice. The temperature rise of the sealing water is smaller than that of the single-stage vacuum pump. Because the sealing water temperature is low, the cooling effect is good, so the efficiency is high.

2. Effectively prevent cavitation

As is known to all, the water pump cavitation is due to the formation of bubbles after water vaporization, bubbles gathered in the low pressure area to form holes, holes by the flow of water to the high pressure area, resulting in a sudden condensation, contraction, bubble burst and impact. If the bubble attached to the impeller surface, and continue to produce water vaporization and steam condensation, the vacuum pump will produce cavitation. The characteristics of the water ring vacuum pump determine that the vacuum pump is prone to cavitation. Cone pump with two – stage pump, due to the reduction of compression heat, sealing water temperature rise small, water is not easy to vaporize. Two – stage vacuum pump will reduce the compression ratio, because the pressure difference is small, bubble is not easy to burst, even if the burst, its energy is much smaller. Therefore, cone pump can effectively prevent cavitation.

3. Can handle excess air leakage

When the amount of air leaking from the condenser increases, the back pressure of the condenser increases. At this point, the difference between the vapor temperature entering the vacuum pump and the condensing water temperature at the vacuum pump inlet is larger, and the condensing effect is better.

Figure 3: Vacuum pump starts

4. Safe and reliable

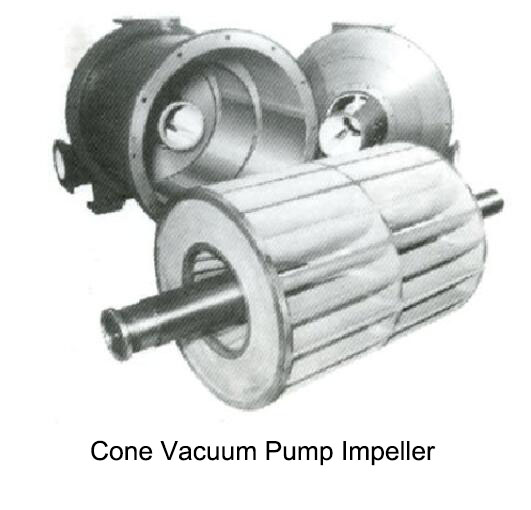

Cone pump because the exhaust port in the lower part, by the direction of compression force is from the bottom up, can offset part of the impeller’s self-weight, so the shaft bear the minimum force, wear small, shaft life than the plane vacuum pump to be long. Cone pump because the exhaust port in the lower part, the impeller is also in the lower part of the vacuum pump, static liquid level is low, so the starting current is small. As a result of the cone pump inlet and exhaust port design on the cone, cone deep vacuum pump body, the whole impeller is cast, the end of the impeller ring reinforcement, is the impeller structure is firm, simple, easy to maintain.

Figure 4: Cone Vacuum Pump Impeller

Third, conclusion

To sum up, cone vacuum pump has high efficiency, energy saving, large margin, cavitation prevention, safe and reliable.

Cone vacuum pump of image:

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)