water ring vacuum pump structure

1、 water ring vacuum pump structure:

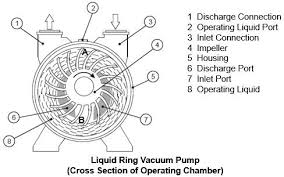

The main components of water ring vacuum pump are impeller and shell. The impeller is composed of blade and hub. The blade has radial flat type and forward bending type. A cylinder space is formed inside the shell, and the impeller is eccentrically installed in this space. At the same time, an air inlet and an air outlet are set at the appropriate position of the shell. The suction port and the exhaust port are arranged on the gas distributor of the impeller side shell to form an axial channel for suction and exhaust.

The shell not only provides working space for the impeller, but also directly affects the movement of working medium (water) in the pump, thus affecting the energy conversion process in the pump.

Before the water ring vacuum pump works, a certain amount of water needs to be injected into the pump, which plays the role of energy transfer and sealing. When the impeller is driven by the motor, the water gets the circumferential speed under the blade. Due to the centrifugal force, the water moves outward, that is, the water tends to leave the impeller hub and flow to the inner surface of the shell, thus forming a moving water ring close to the inner surface of the shell. Because the impeller is eccentric to the shell, the inner surface of the water ring is also eccentric to the impeller. The inner surface of the water ring, the surface of the blade, the surface of the hub and the two side cover surfaces of the shell form many small chambers which are not communicated with each other. Because of the eccentricity between the water ring and the impeller, the volume of the small chamber at different positions is different. With the rotation of impeller, the volume of small chamber changes constantly. If the volume of the small chamber changes from small to large, it can be connected with the inhaled gas, and the gas will be continuously inhaled. When the volume of the chamber changes from large to small, it is closed, so that the inhaled gas will be compressed with the decrease of the volume of the space. After the gas is compressed to a certain extent, the space is communicated with the exhaust port, that is, the compressed gas can be discharged.

2、 water ring vacuum pump working principle:

The working principle of water ring vacuum pump can be summarized as follows: the pump body is filled with an appropriate amount of water as the working fluid. When the impeller rotates clockwise as shown in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring with equal thickness which is determined by the shape of the pump cavity. The inner surface of the lower part of the water ring is just tangent to the impeller hub, and the inner surface of the upper part of the water ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the water ring). At this time, a crescent shaped space is formed between the impeller hub and the water ring, and this space is divided into several small cavities equal to the number of blades by the impeller. If the lower part of the impeller is taken as the starting point, the volume of the small cavity will increase 180 ° before the impeller rotates, and it is connected with the suction port on the end face. At this time, the gas will be inhaled, and when the suction is finished, the small cavity will be isolated from the suction port; when the impeller continues to rotate, the small cavity will decrease from large to small, so that the gas will be compressed; when the small cavity is connected with the exhaust port, the gas will be discharged from the pump.

3、water ring vacuum pump characteristics

Compared with other types of mechanical vacuum pump, water ring vacuum pump has the following advantages

(1.) Simple structure, low manufacturing accuracy and easy processing.

(2.) Compact structure, high speed of pump, generally can be directly connected with motor, without deceleration device. Therefore, with small structure size, large exhaust volume and small floor area can be obtained.

(3.) The compressed gas is basically isothermal, that is, the temperature change of compressed gas is very small.

(4.) Because there is no metal friction surface in the pump cavity, there is no need to lubricate the pump, and the wear is very small. The seal between the rotating part and the fixed part can be directly completed by the water seal.

(5.) Uniform suction, stable and reliable work, simple operation and convenient maintenance.

Water ring vacuum pump also has its disadvantages

1. Low efficiency. Generally about 30%, better up to 50%.

2. Low vacuum. It is not only limited by the structure, but also by the saturated vapor pressure of the working fluid. Using water as working fluid, the limit pressure can only reach 2000 ~ 4000Pa. When oil is used as working fluid, the limit pressure can reach 130 PA.

In short, because the gas compression in the water ring vacuum pump is isothermal, it can pump out flammable and explosive gas. Because there is no exhaust valve and friction surface, it can remove the gas with dust, condensable gas and gas water mixture. With these outstanding characteristics, although it is inefficient, it is still widely used.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)