Difference between cone port and flat port liquid ring vacuum pump

Among liquid ring vacuum pump, there are conical port and flat port. The typical model for flat port comes to 2BE, 2BV, 2SK, etc. While it’s CL, AT series for conical port. Their major different is the structure and application, here we introduce detail as below:

1) Structure

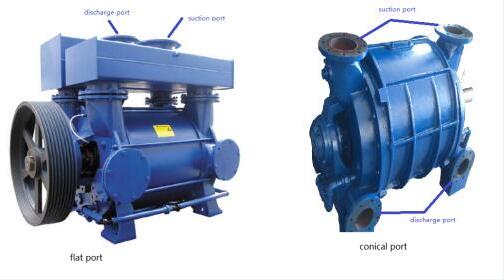

The overall appearance are similar, but the suction and discharge port for flat port are above the pump, while the conical port type discharges through one side. See below photo.

The port structure as below photo

2)Performance

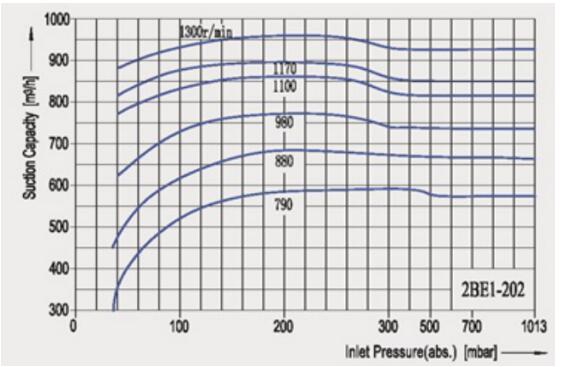

The flat port pump remains stable capacity from atmosphere to its ultimate vacuum. The efficiency is high especially from 200mbar to 1atm. Below curve for reference.

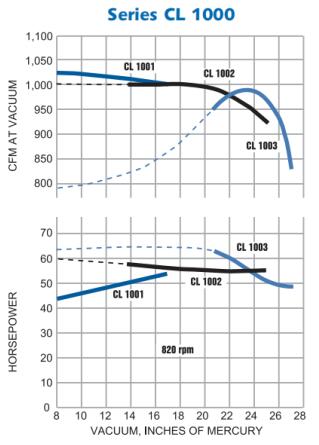

The conical port pump is designed by Nash, used to distinguish the traditional flat port. It can work only in certain pressure range. Taking CL 1000 for example, it’s divided into CL1001, CL1002, CL1003, each number refers different working pressure. CL1001 works only 8~16inHg, CL1002 works only 16~24inHg, CL1003 from 22inHg to 1atm.

3)Industry

The flat port suits for different industry, such as electric power, vacuum distillation and refinery for petrochemical industry, vacuum drying in wooden industry, filtration for mining, gas transportation for gas industry, etc.

The conical port is most often adopted in paper and pulp production.

Tags: liquid ring vacuum pump

Edited by: Shell Hu

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)