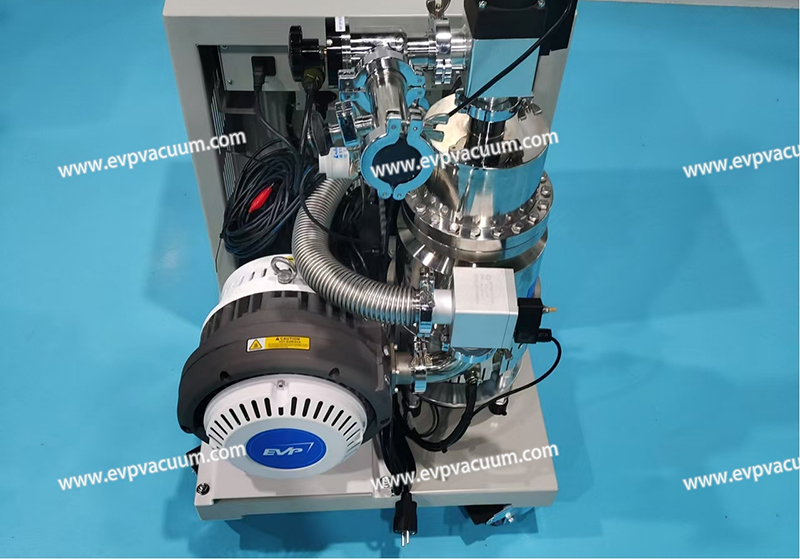

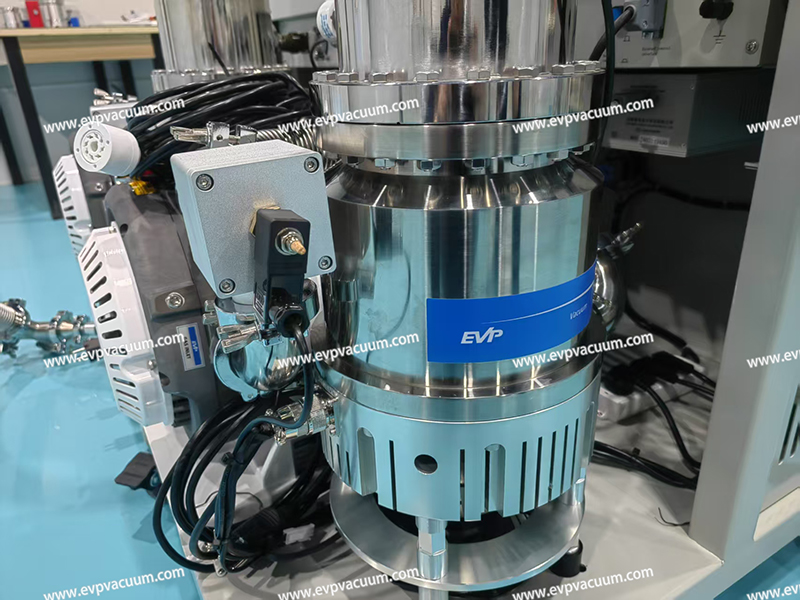

Molecular pump applications and troubleshooting

A molecular pump is a vacuum pump that uses a high-speed rotating rotor to transfer momentum to gas molecules, giving them directional velocity, thus compressing them and driving them towards the exhaust port for removal by the forestage pump. Because the grooves in a simplified traction pump are located on the outer surface of the rotor cylinder or the inner surface of the pump body, the high linear velocity of the outer cylinder can be fully utilized to transfer momentum to the gas molecules, improving the pump’s pumping efficiency.

Since the turbine stage has a large pumping area and a high pumping speed, while the traction stage has a smaller pumping area, at the junction of these two structures, the flow pattern of the gas molecules compressed by the turbine blades suddenly changes. This causes the gas molecule motion to change from ordered to disordered at the junction, resulting in increased backflow and a decrease in pumping capacity.

1. Operating Conditions

The rotor speed reaches 20,000 r/min, therefore the molecular pump has a relatively long start-up time.

Since the gas is in a molecular flow state, a backing pump is required; a rotary vane pump is generally used as the backing pump.

2. Features

Oil-lubricated molecular pump: Requires a small amount of lubricating oil, which is located in the foreground vacuum stage, minimizing contamination of the vacuum chamber.

Grease-lubricated molecular pump: Requires extremely small amounts of grease; when used with a dry pump in the foreground, it can achieve a near-oil-free clean vacuum.

Fully magnetically levitated molecular pump: Requires no lubrication; when used with a dry pump, it can achieve an oil-free clean vacuum environment.

3. Other Common Applications

Analysis (mass spectrometry, electron microscopy, etc.)

Semiconductors (electronic components, integrated circuits, flexible solar cells, etc.)

Optics/Glass (thermal protection, antireflection, reflection, optical filters)

Coating (surface protection, decorative coatings, displays, screens)

Vacuum Metallurgy (vacuum furnaces, vacuum brazing, vacuum sintering, vacuum alloying)

Leak Detection (vacuum systems, vehicle fuel tanks, airbags)

Research and Experimentation (medical MRI, nuclear particle physics, nuclear fusion research, laser applications, and many more)

Lamp manufacturing industry and related industries

4. Molecular Pump Troubleshooting

1. Why does a molecular pump exhibit a phenomenon where one side is hot and the other side is cold?

Cause: Nearby light or other heat sources

Solution: Avoid light or heat sources

2. The oil in the molecular pump turns black during use. Why does the oil turn black? Or how long does it take for the oil to turn black?

Cause: Poor cooling, excessive load

Solution: Check the cooling system and vacuum system

3. During operation, the frequency of the molecular pump drops from normal to a certain level, then returns to normal, then drops to a certain level again, and returns to normal repeatedly. This phenomenon persists even after changing the power supply. How can this be explained?

Cause: Excessive load, insufficient system vacuum

Solution: Check the system

4. Why do molecular pump bearings burn out?

Cause: ① Lack of regular maintenance ② Poor cooling leading to overheating ③ Failure to change the oil in time ④ The pumped gas contains a large amount of dust

Solution: ① Timely maintenance ② Check the cooling system ③ Change the oil in time ④ Isolate from dust

5. Even with a protective mesh, why do large pieces of broken glass still fall into the pump? Causes:

1. Protective netting rupture, upstream pipeline rupture.

2. Solution: Optimize system design.

3. Why does the molecular pump oil return to the upstream pipeline even with a good vacuum?

4. Cause: Oil sump rupture or poor sealing.

5. Solution: Check the oil sump.

6. Why do cracks or deformations appear in the molecular pump oil sump under normal use?

7. Cause: Overheating, heavy load.

8. Objects such as set screws and bolts, such as M5 set screws, frequently fall out of the molecular pump. Does this affect the use of the molecular pump? How should this be resolved?

Cause: This is likely an occasional occurrence, possibly due to a missing balance pin during balancing. It does not affect the molecular pump.

9. How many calipers are needed for safe use of a rubber ring-type molecular pump?

No special limit, at least 3. Depending on the flange size, 3, 6, 12, 24, etc., can be selected.

10. Under what circumstances will the inverter power supply cause program loss or malfunction? A: ① Unstable voltage ② Strong interference ③ High-voltage arcing ④ Deliberate decryption

11. How is excessive noise from a molecular pump defined? Is there a passing standard, and what is it?

A: Less than 72dB is acceptable. The level of noise is difficult to define precisely; specialized instruments and a specific testing environment are required.

12. Are there specific cooling requirements for molecular pumps? For air cooling, what is the required ambient temperature? For water cooling, what are the specific requirements for the water? What are the consequences if these requirements are not met?

A: Pay attention to water temperature and flow rate. Poor cooling can lead to unexplained shutdowns, pump breakage, and blackening of the oil.

13. Molecular pump power supplies have issues with grounding and shielding. What is the best approach?

A: The power supply itself has a grounding wire; simply ensure a good ground connection to the mains grid. Shielding mainly refers to shielding against strong magnetic fields and radiation.

14. The inverter power supply automatically shuts down during speed increase, displaying “Poff”? A: Reason: Low voltage

15. Reasons for molecular pump blade breakage:

A: There are many reasons for the breakage of the rotor and stator of a molecular pump, which can be summarized as follows:

① Misoperation; such as a sudden vacuum break. Because the gap between the rotor and stator blades is very small, if the blade material is thin or soft, the sudden air resistance will cause the blades to deform, which may cause friction between the rotor and stator, leading to breakage.

② Foreign objects falling in; not installing a filter screen is definitely not acceptable. In addition, the object that falls in doesn’t have to be large, but if it is hard enough, it will still cause damage. At best, it will cause the blade edges to be jagged; at worst, it will shatter the blades. Therefore, equipment manufacturers now try to install molecular pumps at a 90-degree angle to the side or upside down to avoid foreign objects falling in.

③ Unstable voltage, especially damaging to magnetic levitation molecular pumps.

④ Poor efficiency of the backing pump; we know that most of the gas in the chamber is first extracted by the backing pump, and the molecular pump will only start when a certain vacuum is reached. If the backing pump is inefficient, the molecular pump will struggle, resulting in slow start-up, longer pumping time, higher current, and increased pump temperature. ⑤ Improper dynamic balancing during molecular pump maintenance is a critical technical issue. Poor dynamic balance leads to greater vibration, lower pumping efficiency, and excessive wear on the bearings. ⑥ Using non-original standard bearings, or bearings with substandard performance and dimensions.