dry screw Vacuum Pump in Petrochemical Industry Gasoline Steam Recovery

With the increasing attention to environmental protection in our country, the state or industry has formulated various laws, standards and regulations to strictly restrict the emission of gasoline vapor. It is required that oil and gas recovery devices must be added to oil storage and gas stations, and meet the standards of emission concentration < 25g / M 3, and oil and gas treatment efficiency > 95%.

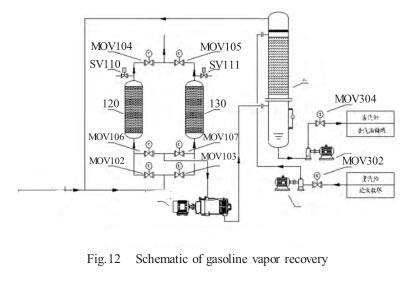

The oil and gas recovery unit uses active adsorption to realize the separation of hydrocarbon components and air in oil and gas, so as to reach the emission standard. The regeneration of active carbon is realized by vacuum desorption, so as to achieve the purpose of recycling. The vacuum desorbed oil and gas is absorbed by the gasoline spray method, which converts the oil and gas into gasoline and recovers it.

The dry screw vacuum pump is a key equipment in the gasoline vapor recovery device. The extracted gas is volatile gasoline vapor, mainly composed of C4, C5, C6 and other gasoline vapor. The principle of the device is shown in Figure 12.

In consideration of safety, generally, the operating temperature of the pump is required to be controlled below 80 ℃ for gasoline recovery. In addition, cooling water cannot be provided in most sites, and the available coolant is gasoline. In order to reduce the operating temperature of the pump, the pumping speed is 800m3 / h For the above large pump, in addition to the pump body jacket into the gasoline, the most effective way is to inject a proper amount of gasoline into the pump cavity (at the highest temperature point), and reduce the temperature in the pump cavity through the evaporation and heat absorption of gasoline.

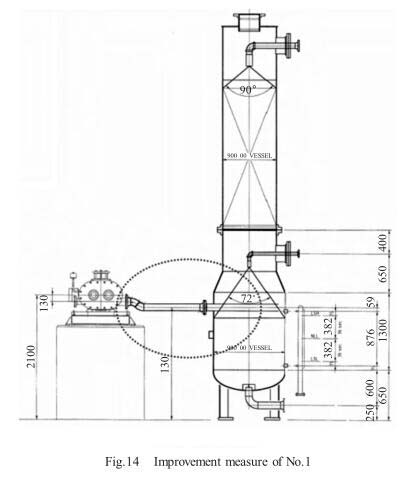

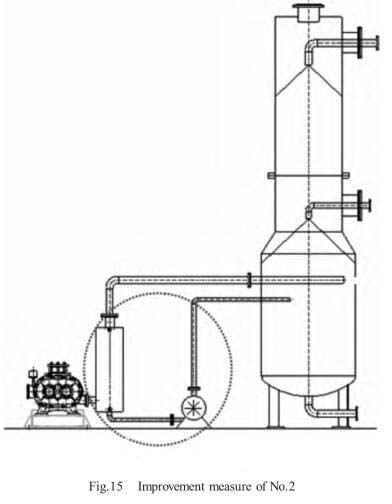

In the oil vapor recovery process of screw vacuum pump, the condensed gasoline will accumulate at the exhaust port of the pump. If not discharged in time, it will cause abnormal vibration and noise of the pump. Therefore, the following two improvement measures can be taken.

Measure 1: the exhaust pipe of the pump shall be inclined downward, and the position of the exhaust pipe shall be lower than the position of the exhaust port of the pump (see Figure 14)

Measure 2: install a circulating pump at the lowest position of the exhaust port or muffler of the pump to eliminate the liquid accumulation at the exhaust port. (see Figure 15)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)