Dry screw vacuum pump in plastic workshop

Many people don’t know what kind of operation the vacuum blister machine uses. Simply introduce the concept and main application of the vacuum blister machine, as well as the advantages of the dry screw vacuum pump in the suction machine, and the selection of the special screw vacuum pump for the blister machine

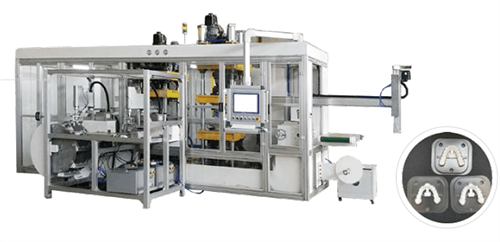

Vacuum blister machine (also known as thermoplastic molding machine) is a machine which can make PVC, PE, PP, pet, hips and other thermoplastic coiled materials into various shapes of advanced packaging and decoration boxes, frames and other products.

Principle of vacuum Blister molding machine: Blister molding is also called thermoplastic molding. This molding process mainly uses the vacuum suction generated by vacuum pump to make PVC, pet, PETG, APTT, PP, PE, PS [1] and other thermoplastic plastic sheets after heating and softening into various shapes of true empty cover, plastic tray, bubble shell, etc.

The main structure of vacuum blister is composed of feeding, pulling, electric heating furnace, lower brake, multi-functional adjustable size, lower die plate, upper mold, upper brake, knife brake, slicing, film release and vacuum device, etc.; the pneumatic device is the main power source, and its pulling and feeding are controlled by electric, reducer, time relay, intermediate relay, travel switch and other electrical appliances System.

The main applications of suction molding machine are as follows:

1. Plastic packaging industry (blister packaging, plastics, batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration)

2. Food packaging industry (fast food box, fruit tray, biscuit box)

3. Pharmaceutical industry (pill packaging, tablet packaging)

4. Industrial cooling tower cooling water guide plate, etc

5. Manufacturing industries such as decorative three-dimensional relief pattern, plastic ceiling, wallboard, automobile materials, sanitary equipment, etc.

6. Suitable for production of various color sheets: PE PS, PVC, PMMA, ABS, PMMA; flocking sheet; environmental protection sheet APET, pet, PP, etc.; photodegradation material; biodegradable material and other plastic products.

Vacuum suction molding machine is a variety of sizes and types of plastic forming equipment, one of the most critical equipment is the vacuum pump. The vacuum pump can ensure that the plastic film or plastic sheet is accurately molded according to the mold. At present, in the production and processing of food, beverage, candy, cultural goods, hardware tools, daily necessities and chemical products, vacuum pump is needed to achieve the purpose of Blister molding. The so-called vacuum suction molding machine, its working principle must be matched with vacuum pump.

The vacuum suction machine market is very large, many vacuum pump manufacturers are vigorously developing this field. But the vacuum pump of matching blister machine on the market is of different quality, which is praised respectively. As a customer, how do you choose the right vacuum pump for the vacuum machine?

The vacuum pump selection of vacuum suction machine depends on the parameters first, and the following two indexes are taken as reference:

1: See vacuum degree: the so-called vacuum degree is a kind of expression of air rarefaction, which is usually expressed in PA, MB Ba, mm Hg and other units. After the forming of Blister products, the product bubbles are mostly due to the vacuum degree not meeting the requirements, which leads to product defects. Compared with the products with deep grooves, the vacuum requirements are relatively high.

2: See the flow: refers to the unit time vacuum pump to pump out the fluid flow through the closed pipe or effective section. The vacuum flow rate is an important sign to measure the suction. When we select the vacuum pump, we should pay attention to the specification and thickness of the product to calculate the amount of air that needs to be removed in an hour or a minute, so as to determine the amount of vacuum pump that needs to be evacuated.

Advantages of the application of dry screw vacuum pump in vacuum suction machine are as follows:

Power saving: 30%;

Maintenance: the maintenance workload of field maintenance workers is greatly reduced;

Maintenance Premium: Accounting in two years, saving 30%.

Half the noise

Double performance

Half of maintenance

Greatly reduced floor space

Simple and fast installation

Save installation space: all peripherals are packaged as a whole to provide customers with one-stop plug and play