Dry Vacuum Pumps Introduction

Recently, many friends consulted and feedback their production of liquid ring vacuum pumps because of high temperature in summer, vacuum can not go up, impellers are often replaced due to corrosion and cavitation, oil-free screw pump, claw pump rotor is often stuck in the car, and because of the corrosion of vacuum can not go up, there is fuel injection phenomenon at the exhaust port. Although the maintenance of various phenomena does not cost much money, but affect production, a team of people waiting for the pump to repair, the following people stare at, the upper leader looks bad, very embarrassing!

Therefore, we will introduce the dry vacuum pump to you in this series. Dry vacuum pumps are mainly used in semiconductor industry, chemical industry and film industry. The foreign dry pump market is in a booming stage. For example, in Japan, the semiconductor industry has replaced oil-sealed mechanical pumps with dry vacuum pumps, while in Europe and the United States, more than 45% of the semiconductor industry replaced oil-sealed mechanical pumps with dry vacuum pumps, greatly improving the performance and quality of products.

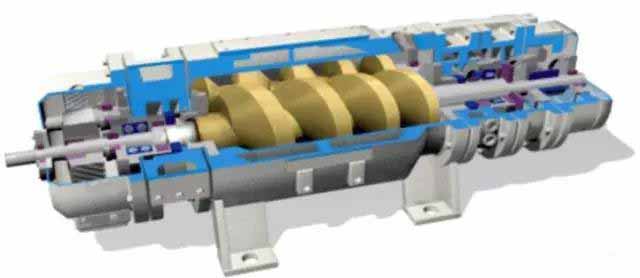

In order to meet the requirements of different application fields and different working conditions, there are screw vacuum pumps, multi-stage Roots vacuum pumps, multi-stage claw vacuum pumps, reciprocating piston vacuum pumps, scroll vacuum pumps and turbine oil-free vacuum pumps abroad. The limit pressure of the dry pump ranges from 10 Pa to 10-2 Pa, and the pumping speed ranges from 20 m3/h to 500 m3/h.

Dry Vacuum Pump Introduction and Principle

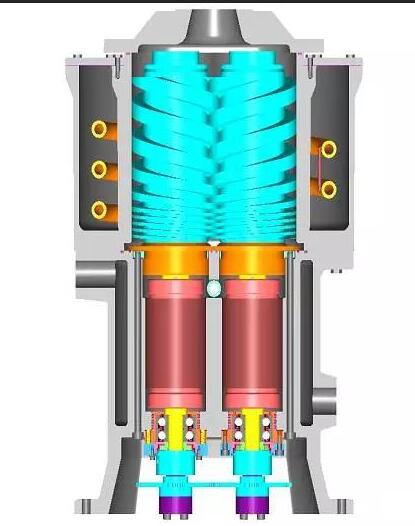

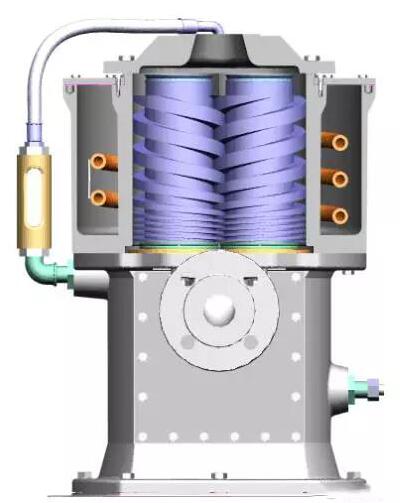

This is a vertical twin-screw dry vacuum pump. Its principle of suction and exhaust is the same as most of them. It is a suction equipment which uses a pair of screw to synchronize high-speed reverse rotation in the pump housing and produces the effect of suction and exhaust.

When dry vacuum pump works, it runs smoothly without friction, low noise, and no lubricant is needed in the working chamber. Therefore, dry screw pump can extract a large amount of water vapor and a small amount of dust. Because the screw is made of variable pitch structure, compared with the equal pitch structure, the limit vacuum is higher, and the power consumption is lower. It has the advantages of energy saving and maintenance-free. It is an updated product of oil-sealed vacuum pump.

Two-year spare parts are standard O-rings. The top-down conveying mode can reliably handle moisture and dust with liquid, and no filter is needed. Optimized screw shape design minimizes power consumption. Simple design can make the pump chamber disintegrate completely in one hour and easy to clean and maintain.

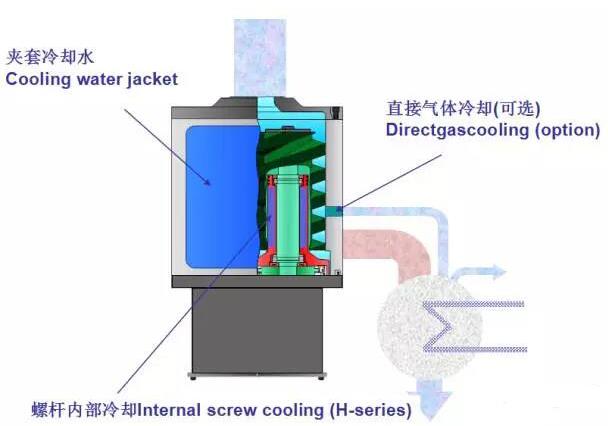

Unique Cooling Method

Many pump rotors are stuck because of inhalation of dust and crystalline substances, high temperature polymerized substances, and sublimation of heat sensitive substances. Another reason is that the gap between the rotors is blocked because of long-term operation, the rotor will be deformed due to thermal expansion and contraction, resulting in the stuck of the pump.

dry vacuum pump cooling mode :

At present, jacket cooling water is widely used to cool the rotor of dry pumps on the market.

The cooling system of some vertical screw vacuum pumps is more unique, such as adding coolant cooling and direct gas cooling inside the screw, maintaining the temperature of the inner surface well, not too high or too low, and always maintaining a suitable temperature to prevent the decomposition of the heat-sensitive substances being pumped, and high-temperature and easily polymerized substances, such as HCN and MMA manufacturers, are more appropriate. All right.

What about removing inflammable, explosive and corrosive media?

It is well known that corrosion is caused by the reaction of acidic and alkaline ions in solution with metals. The higher the temperature, the faster the corrosion rate. The general vacuum pump uses some anticorrosive material or some anticorrosive coating on the rotor to slow down the corrosion rate.

However, due to the harsh thermal conditions in the operation of dry vacuum pumps, it is not suitable for oil-free dry vacuum pumps to use the above corrosion-resistant materials to treat corrosive media.

In addition, the use of high nickel plating iron coating material, once the occurrence of small cracks will lead to rapid electrochemical corrosion of the material. So, as long as the special design can reliably control the temperature of the equipment to maintain the corrosive medium in the gas phase state, there is no ion form is there no corrosion? The answer is yes. With its own advanced cooling system, the pump can adjust the temperature of the pump chamber and rotor, so that there are no ions in the pump chamber, and all of them are gasified, thus avoiding corrosion. Therefore, the screw dry vacuum pump rotor uses stainless steel without any coating, which reduces the cost and increases the safety performance.

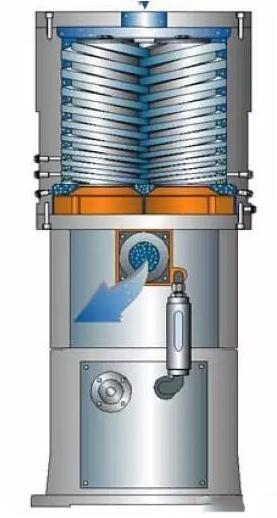

Dry Vacuum Pump Sealing :

There is neither shaft seal between the pump and the outside world nor seal between the pump chamber and the cooling circulating water circuit, so toxic and harmful media can be removed.

Most of the pump failures are caused by wear and tear of the shaft seal, and there is only one non-contact seal on each shaft of the pump. There is no shutdown caused by the damage of the shaft seal, and the leakage of the shaft seal causes the oil in the gear box to be pumped into the pump, resulting in vacuum environment and exhaust pollution.

Control System composition:

Dry vacuum system also has the best control system, with independent workstations and buses, which can solve the problems of temperature, pressure, speed, motor synchronization, start-stop, valve switch and self-cleaning control of the pump itself, and increase the temperature measuring points where there may be temperature rise, thus enhancing the safety of the system. The dry pump system can adapt to the harshest environment in chemical industry and pharmaceuticals.

It consists of the following three parts:

Built-in basic driver module;

Data bus control cabinet;

Coolant pump control and explosion-proof motor control center.

Dry Vacuum Pump Characteristics :

Some vacuum pumps are driven synchronously by two motors, which ensures full speed and torque control while maintaining contact between components while running.

Unsealed design to ensure no leakage;

To meet the requirements of the new ATEX explosion-proof regulations, the inner surface temperature is controlled. Because it can maintain the minimum internal temperature, it can control the condensation of pumping gas and the damage effect caused by corrosion. It can easily transport corrosive medium and safely transport flammable and explosive gas.

1) Clean and environmental protection;

2) High vacuum;

3) Anti-corrosion design (patented technology);

4) Can extract condensable gas and a small amount of dust gas (patented technology);

5) Special shaft seal design to eliminate mutual contamination between pumped medium and lubrication system;

6) Anti-overload design;

7) smooth operation;

8) High standard configuration;

9) Complete configuration of accessories

10) Quality and sound supply of spare parts.

Dry vacuum pump is the trend of future industry development. Although it is not used much now, besides the high price, there are also users who do not understand the dry vacuum pump in place, and can not see the future economic benefits brought to the enterprise, but dry vacuum pump makes the working volume oil-free, so it brings many benefits.

Some vertical screw vacuum pumps meet the requirements of the new ATEX explosion-proof regulations by controlling the inner surface temperature. Because it can maintain the minimum internal temperature, it can control the condensation of pumping gas and the damage effect caused by corrosion. It can easily transport corrosive medium and safely transport flammable and explosive gas.

It is suitable for treating medium containing solid particles and does not need to add filters.

Minimum maintenance requirements, the pump has no gearbox, and there is no need to replace and test the lubrication system for the pump. Average trouble-free time of 20,000 hours;

Fully electronic intelligent design can easily connect with DCS system in all directions. Local and remote control can be realized by modem connection.

The modular design of auxiliary modules can satisfy a large number of even the most demanding process applications.

The design can meet different pressure requirements: pressure ratio can be as high as 100,000:1 (inhalation pressure < 0.01 mbar adiabatic pressure);

The suction capacity can reach 1,000 m3/h (in the development of pumps with larger suction capacity, the combination of mechanical booster pump and dry pump can be used to meet the requirements of large suction capacity at present).

Noise level below 75Db (A) (Noise below the decibel of the interior of a high-end car)

Easy maintenance, can quickly and easily disassemble and replace the internal parts of the pump.

The whole machine has passed the certification of European ATEX explosion protection regulations.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)