Electron beam welding technology and applications

1.What is electron beam welding?

Electron beam welding is a type of fusion welding that uses a concentrated high-speed electron beam to bombard the joints of the workpiece to generate heat energy to fuse the metal.

2.Basic principles of electron beam welding

Under vacuum conditions, electrons escape from the emitter (cathode) in the electron gun. Under the action of the accelerating voltage, the electrons are accelerated to 0.3 to 0.7 times the speed of light, and have a certain kinetic energy. Then through the action of the electrostatic lens and the electromagnetic lens in the electron gun, the electron beam is converged into an electron beam with a high power density. This electron beam hits the surface of the workpiece, and the kinetic energy of the electrons is converted into heat energy, causing the metal to quickly melt and evaporate. Under the action of high-pressure metal vapor, a small hole is quickly “drilled” on the surface of the workpiece, also called a “keyhole”. With the relative movement of the electron beam and the workpiece, the liquid metal flows around the small hole to the back of the molten pool. And cools and solidifies to form a weld.

3.Advantages of electron beam welding

(1)High heating power density.

(2)The weld depth-to-width ratio (H/B) is large.

(3)The welding speed is fast and the thermophysical properties of the weld seam are good.

(4)Weld seam purity is high.

(5)The welding process parameters have a wide adjustment range and strong adaptability.

(6)Many materials can be welded.

4.Applications of electron beam welding

Electron beam welding was first used in the manufacturing of aircraft engine core components. The typical representative is the large American passenger aircraft engine-MF56 turbofan engine. The low-pressure compressor rotor, high-pressure compressor rotor, combustion chamber and other core components of the core engine are all made of vacuum. Electron beam welding has improved the quality, structural design, structural manufacturing accuracy and service life of the engine.

In other industrial sectors, electron beam welding is mainly used for high-pressure gas cylinders, nuclear power plant reactor internal component cylinders, automobile gears, electronic sensors, radar waveguides, etc. In addition, electron beam welding is also used in some copper cooling tuyere of steel-making furnaces and steam turbine blades.

In the future, electron beam welding will have greater development in the mass production of complex parts. In the aerospace industry, electron beam welding technology will continue to expand its application, and develop online detection technology for electron beam welding, and in energy, It is of great use in the nuclear industry and heavy machinery manufacturing. As the application field of electron beam welding expands, multifunctional electron beam welding equipment and integrated processes as well as the flexibility of electron beam welding machines will become increasingly important.

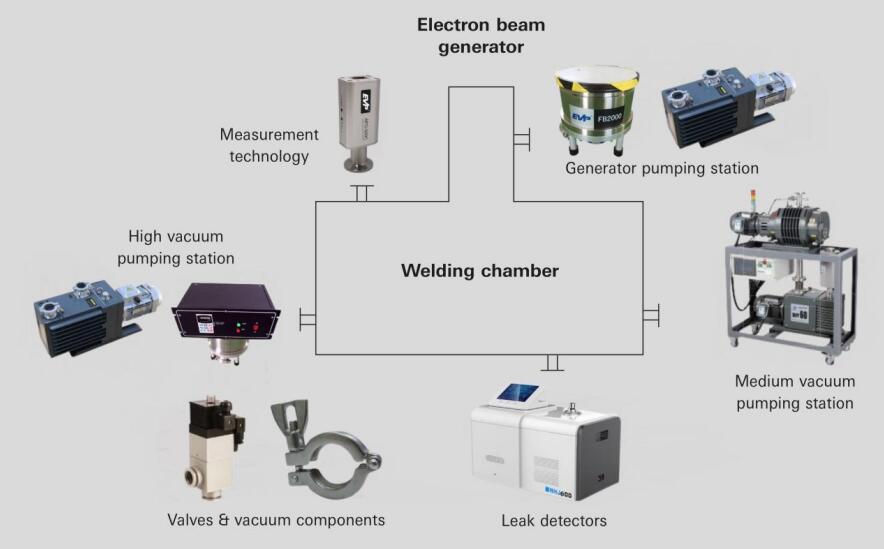

5.Vacuum Requirements for Electron Beam Welding

On the electron beam generator, after the initial evacuation process (time requirements are usually not critical) is completed, the vacuum pump must permanently maintain the background pressure in the high vacuum range. The requirements in the welding room are even higher. Vacuum chamber volumes may vary from a few liters to hundreds of cubic meters. Regardless of the size of the vacuum chamber, short cycle times must be ensured. This means that the vacuum system needs to guarantee a very fast pumping speed until the specified operating pressure is reached, which is usually in the upper part of the high vacuum range. Therefore, an important criterion for a vacuum pump is its very high suction speed capability.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)