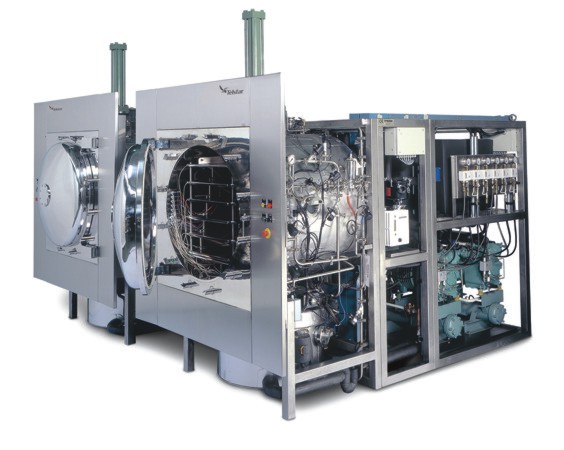

Freeze dryer vacuum pump

Vacuum Pump for Freeze Dryer Classification and Composition

Freeze dryer is also called freeze dryer. Its vacuum system can be divided into several categories: oil-free vacuum unit, oil vacuum unit, vacuum system, vacuum unit, continuous processing vacuum equipment and so on.

The vacuum system of freeze dryer or freeze dryer consists of five parts:

1.Vacuum group of oil-free engine: No oil is used as working fluid box and no organic material is used for sealing.

2. Oil vacuum unit: using oil as working fluid or sealing with organic materials.

3. Vacuum system: It is made of vacuum container and produces vacuum, measures vacuum and controls vacuum.

4 Vacuum Unit: It consists of generating vacuum, measuring vacuum and controlling vacuum.

5. Continuous Vacuum Processing Equipment: It is capable of continuously feeding materials or work pieces to vacuum containers, and can be exported from the vacuum chamber without interrupting the continuous process of the equipment.

What is the function of vacuum pump on freeze dryer?

With the increase of condensation temperature, the pressure in the drying chamber and the cold trap chamber rises, and the ambient temperature is between +15 and +25. The vacuum pump must work under the condition of opening the air ballast valve. 120 millibars correspond to -40, 0.040 millibars correspond to -50, 0.011 millibars correspond to -60, and when the condensation temperature is below – 50, and the pressure is less than 0.120 millibars, the working efficiency of the machine will be improved. High.

1. What is freeze-drying?

Freezing means driving water out of the frozen material. Drying is achieved by sublimating the frozen water directly into a gaseous state in vacuum. The temperature of the material being lyophilized is below – 10 C. The purpose of freeze-drying is to preserve dehydrated products and restore the characteristics of raw materials after adding water. At very low temperatures, the protein is dried, and the other major chemical bonds remain unchanged. By freeze-drying, materials such as tissues, tissue extracts, bacteria, vaccines and plasma become dry, so that no changes in enzymes, bacteria and chemistry occur. It can be said that freeze-drying is the best way to preserve tissues and tissue components sensitive to biological characteristics.

2. Application of ALPHA 1-2 is an effective tool for freeze-drying of lipid and liquid materials in ampoules, vials, beakers, plasma bottles or dishes. It is a general equipment for laboratories and technical schools, and can complete the whole process of freeze-drying process: – freezing, – freeze-drying, – re-drying. ALPHA 1-2 freeze dryer is suitable for drying bacteria, viruses, plasma, serum, antibodies, vaccines, medicines, vitamins, yeasts, plant extracts for biochemical research, etc.

3. installation

The freeze dryer should be laid flat, and the ambient temperature should be between + 15 C and + 25 C. The cooling part adopts air-cooled heat dissipation, which must ensure enough air circulation space. Therefore, the installation position must ensure that the machine is at least 30 centimeters apart from the wall and away from the heat source. If the ventilation is poor or the ambient temperature is too high, the temperature and pressure of the refrigeration system will rise, and/or the refrigeratory will be closed by a voltage protection switch.

3.1 Installation site of power socket has 230V, 50Hz power socket and 16A insurance.

3.2 The defrosting water defrosting water discharge valve (21) is on the right side of the machine. The drain pipe should be connected to the water receiving container through the drain pipe on the side plate of the box. Drainage can also be directed to the downstream with a 1/2-inch water pipe, which can pass through the side or rear panels of the chassis. It is necessary to keep the outflow unobstructed. Otherwise, if the drainage valve is opened, there will be a risk of sucking water and dirt in case of low pressure. Open the right side panel to find the water pipe interface of the defrosting water discharge valve.

3.3 During the main drying process, the vacuum pump must work under the condition of opening air ballast valve to derive oil mist. The exhaust pipe of RZ-2 vacuum pump is connected with 1/2 inch pipe DUO 004 or DUO 008, and 3/4 inch pipe leads to outdoor or exhaust passage. Attention should be paid to the installation of pipelines: do not cause condensation in the pipeline to have the possibility of reflux vacuum pump, pipeline ascending section is best equipped with separators (bottle washing, etc.). If the oil mist can not be derived, it is recommended to install exhaust filters with order numbers of 125501 and 125503 to prevent the oil mist discharged by vacuum pumps from polluting the air under working pressure. The exhaust filter should be fixed on the exhaust pipe of the vacuum pump. There is an overpressure valve on the filter, indicating the saturation of the filter. Clean or replace filter packing at the latest before overpressure valve operation. The accumulated oil can be seen in the viewing glass and discharged through the drain screw.