Dry vacuum pump degassing in steel

Dry vacuum pump in degassing of steel of application

In many industries, the use of vacuum pumps to remove gas, steam and water in processed products, to improve the quality of products have a very big help. For example, in a steel plant, a dry vacuum pump can extract hydrogen from molten steel, improving the quality of steel. Let’s introduce this knowledge in detail:

Vacuum degassing is a key step in the production of high quality steel alloy products and is the only way to manufacture special grades of steel for the automotive, aviation and railway industries. During the production process, molten steel may contain excessive hydrogen and carbon elements. In the past, removing hydrogen required waiting for the metal to cool down, which prolonged manufacturing time. The current method is to use a dry vacuum pump to remove hydrogen, thus avoiding defects that may affect the integrity or performance of the steel.

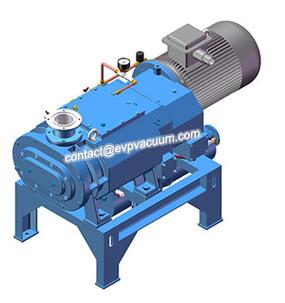

The use of vacuum pumps for degassing and carbon removal not only reduces defects, but also has other advantages: low carbon steels are more malleable and easier to shape through embossing and molding machines. Dry vacuum pump, without steam as the working medium, so the most suitable for degassing steel applications.

Such as other vacuum pumps that need medium, the high temperature of steam or gas and large amount of dust can lead to quality degradation of steel. And the dry vacuum pump completely without oil, so can run in this kind of harsh environment, on the one hand can shorten the production time of steel, on the other hand to improve the quality of steel, is the ideal choice of vacuum pump.