Two stage liquid ring compressor

Summary:

2 sy series liquid ring compressor and complete sets of equipment due to the compression of gas in the water (liquid) ring compressors is isothermal compression process, (when added liquid temperature of 15 ℃ – 25 ℃, the temperature rises to 5 ℃ – 10 ℃), so very suitable for compression of flammable and explosive gases, such as chemical industry, petrochemical industry of polyethylene, oxide, vinyl chloride monomer, sulfur dioxide, hydrogen sulfide, benzene, ethylene and chlorine gas, etc.

Its characteristics are:

1. Stainless steel material and reliable sealing element are used; zero leakage is achieved by air pressure delivery;

2, can pump containing a lot of water vapor and containing small particles of gas, when the replacement of other liquids to do the work fluid, but also pressure to send dissolved in water or not easy to contact with water gas

3. Complete sets of parts can be supplied: electric control system, gas-liquid separator, heat exchanger, condenser, etc.

2SY series liquid ring compressor are widely used in petroleum, chemical, pharmaceutical and other industries for gas compression and transportation, tail gas recovery. It is characterized by high pressure, compact structure, reliable operation, convenient operation and high pumping speed in high pressure area. Because in the compression process, is in the isothermal state, so in the compression of flammable, explosive gas, not easy to occur dangerous, so it is more widely used.

Model representation method:

The model of 2SY series pump is represented by a combination of 4-bit words (letters) and Numbers. The marks are as follows:

<1> S Y — <2>

Among them:

<1> represents a series, for example, “2” represents two levels, and no addition represents a single level

SY is the name of high-pressure water-ring compressor series

<2> represents the maximum pumping speed of the pump, unit m3/min

Model example: “2sy-12” is a two-stage liquid ring compressor with a maximum gas volume of 12m3/min

2SY series liquid ring compressor

Technical parameters

| Model | Discharge capacity

m3/min |

Working pressure range

MpaG |

Motor power

KW |

Rotating speed

r/min |

Suction and discharge caliber

mm |

Water supply

L/min |

| 2SY-1.5 | 1.5 | 0.3-0.6

Performance curve graph. |

22 | 2940 | 65 | 60-100 |

| 2SY-3 | 3 | 37 | 2940 | 65 | 80-120 | |

| 2SY-6 | 6 | 75 | 2970 | 65 | 120-150 | |

| 2SY-9 | 9 | 110 | 1450 | 125 | 150-170 | |

| 2SY-12 | 12 | 132 | 1450 | 125 | 170-200 | |

| 2SY-15 | 15 | 185 | 1450 | 125 | 200 | |

| 2SY-20 | 20 | 250 | 980 | 200 | 250 | |

| 2SY-25 | 25 | 315 | 980 | 200 | 300 | |

| 2SY-30 | 30 | 355 | 980 | 250 | 350 | |

| 2SY-35 | 35 | 400 | 980 | 250 | 400 |

Note:

1. The motor power in the table is the supporting motor power under the following circumstances: SY series has exhaust pressure of 0.25MpaG(2)2SY series has exhaust pressure of 0.55MpaG

2. The maximum exhaust pressure of 2SY can reach 0.8mpag.

3, discharge pressure requirements are different, corresponding matching motor power also change.

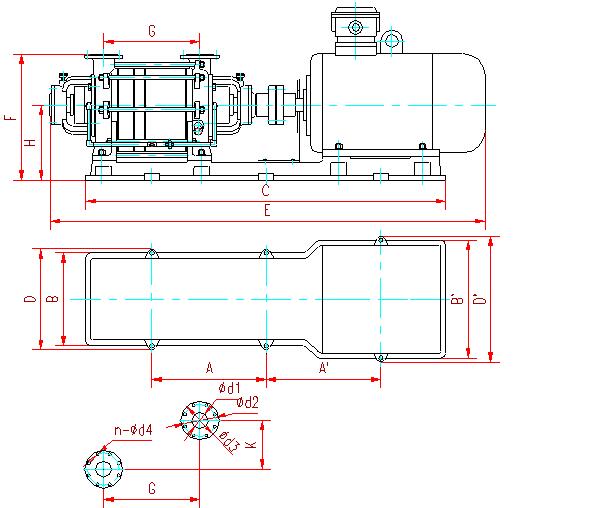

Installation dimensions

|

model

|

A

|

A’

|

B

|

B’

|

C

|

D

|

D’

|

E

|

F

|

H

|

G

|

K

|

d1

|

d2

|

d3

|

d4

|

n

|

|

2SY-6

|

525

|

525

|

490

|

590

|

1580

|

550

|

650

|

1920

|

640

|

380

|

295

|

200

|

60

|

135

|

160

|

14

|

6

|

|

2SY-9

|

625

|

625

|

572

|

640

|

1930

|

622

|

690

|

2310

|

775

|

462

|

465

|

300

|

100

|

180

|

215

|

18

|

8

|

|

2SY-12

|

680

|

645

|

572

|

725

|

2050

|

622

|

775

|

2540

|

775

|

462

|

520

|

300

|

100

|

180

|

215

|

18

|

8

|

|

2SY-15

|

700

|

685

|

572

|

725

|

2180

|

622

|

775

|

2740

|

805

|

492

|

600

|

300

|

125

|

200

|

235

|

18

|

8

|

Related videos

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)