frequency converter in roots vacuum pump

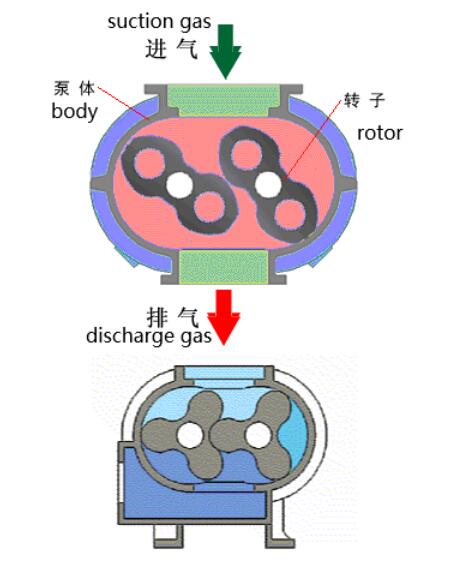

vacuum pump working principle:

Vacuum pump refers to the device or equipment that uses mechanical, physical, chemical or physicochemical methods to extract air from the container to obtain vacuum. Generally speaking, vacuum pump is a device to improve, generate and maintain vacuum in a certain closed space by various methods.

The working principle of Roots vacuum pump is similar to roots blower. Due to the continuous rotation of the rotor, the extracted gas is drawn into the space V0 between the rotor and the pump shell from the air inlet, and then discharged through the exhaust port. Because the V0 space is completely closed after suction, there is no compression and expansion in the pump chamber. However, when the top of the rotor turns around the edge of the exhaust port and the V0 space is connected with the exhaust side, a part of the gas will recoil into the space V0 due to the high gas pressure on the exhaust side, which makes the gas pressure suddenly increase. When the rotor continues to rotate, the gas is discharged from the pump.

The negative pressure PID automatic regulation control can be realized by using the inverter control. The suction of negative pressure air is fed back by the negative pressure sensor of the air outlet, and the motor running frequency is automatically adjusted to achieve the energy saving effect.

Frequency converter plus source signal 7 Inch Touch screen to realize communication operation of complete system.

Functional features

Touch screen displays feedback pressure, set pressure, operating frequency, running current, etc;

The frequency converter has built-in PID regulation and built-in temperature PT100 input detection. When the internal temperature of the equipment reaches the set temperature, the frequency converter TA and TB output relay signals to control the heat dissipation of the cooling fan.

Parameter setting

| P0.03=2 | Communication control start stop |

| P7.00=1 | Closed loop control operation mode |

| P7.05=0.030MPA | According to the actual requirements of the site pressure setting |

| P7.11=2.5 | |

| P7.26=1 | |

| P7.27=0.080MPA | According to the actual negative pressure sensor settings |

Application site