Heavy hammer hydraulic control slow closing check butterfly valve

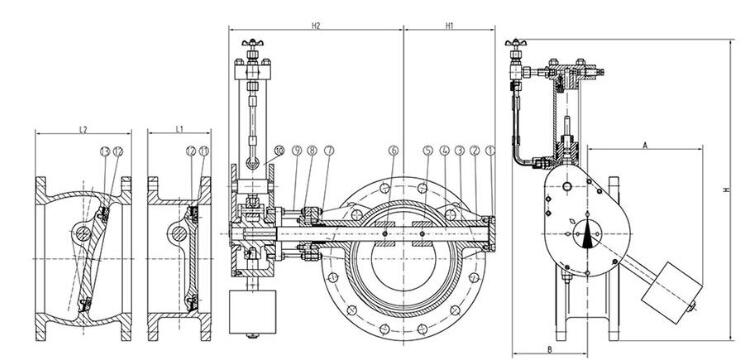

Heavy hammer hydraulic control slow closing check butterfly valve (special for pump station and industrial pipeline)

1、 Product introduction:

Hydraulic control slow closing check butterfly valve series products are widely used in water conservancy, thermal power, water supply and drainage, chemical engineering, metallurgy and other pumping stations. It is mainly installed at the outlet of water pump to replace the function of check valve and gate valve. When working, the valve cooperates with the water pump. According to the pre-set procedure, the valve is closed in two stages: quick closing and slow closing. It can effectively eliminate and restrain the water hammer in the pipeline. It is an ideal equipment to ensure the safety and reliability of the water pump unit and pipe network system.

Size:

The hydraulic station and electrical control box of this series of valves are separated from the valve body, and can be installed nearby or in combination. The valve body can be installed horizontally or vertically.

This series of valves can be divided into accumulator type and heavy hammer type according to energy storage mode.

This series of products are also known as: “hydraulic control check butterfly valve, hydraulic control check valve, hydraulic control slow closing butterfly valve, hydraulic control butterfly valve”, etc.

It has the following characteristics:

1. It can replace the stop valve and check valve at the outlet of the water pump, and integrates the mechanical, electrical and hydraulic functions, and occupies a small area.

2. High degree of automation, local, remote and linkage control.

3. The electrical system can adopt PLC intelligent control system or ordinary relay type system.

4. The motor power of the hydraulic system is small, the working efficiency is high, the pressure maintaining performance is good, and the oil pump starting interval is long.

5. The hydraulic system has the function of automatic pressure maintaining, with long holding time, and the starting interval of oil pump can reach 500 hours.

6. It has obvious opening indication and mechanical limit adjusting mechanism, and the stroke device is waterproof and dustproof, with stable performance and long service life.

7. The electrical operation interface is humanized and diversified. It can be designed with ordinary button type, text type and touch screen type, and the latest man-machine operation interface can be designed according to the needs of customers.

2、 Technical parameters

Nominal diameter: DN 100 ~ dn4000

Nominal pressure: pn2.5 ~ pn64

Applicable media: clear water, sediment water, sea water, reservoir water, oil, gas, etc

Medium temperature: ≤ 80 ℃

Valve opening time: 3 ~ 120 seconds (adjustable)

Valve closing time: 3 ~ 120 seconds (adjustable)

Power supply: AC380V

DC 220 V, DC 220 V or DC 24 V

Remote control: open valve, close valve, stop, etc

Remote signal: passive switch signal, 4 ~ 20mA analog valve position feedback signal