How to choose right type of vacuum pump

Vacuum pump vacuum pump is a kind of rotary variable volume vacuum pump which can be used only with the cooperation of the front pump. It has a large pumping speed in a wide pressure range. It is not sensitive to dust and liquid vapor contained in the extracted gas. It is widely used in metallurgy, chemical industry, food, electronic coating and other industries.

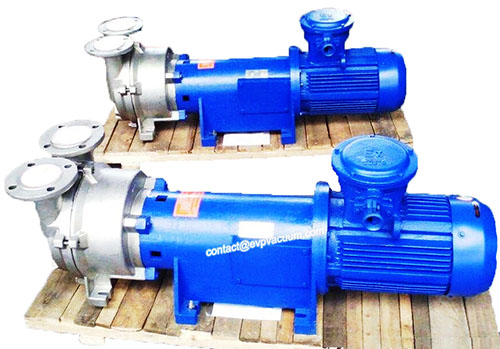

There are 2x, 2XZ rotary vane vacuum pump, ZJ, ZJH roots vacuum pump (ZJH is patented vacuum pump), 2SK, SK liquid ring vacuum pump, 2BV, 2be liquid ring vacuum pump, h, 2h slide valve vacuum pump and other models.

Vacuum pump working principle:

1. First, we should fully understand the composition of the extracted gas. For example, the gas does not contain condensable vapor, particle dust, corrosiveness and explosiveness. If the gas contains steam, particles and corrosive gas, auxiliary equipment, such as condenser, dust remover, etc., shall be installed on the air inlet pipeline of the pump. If the extracted gas is corrosive, stainless steel shall be used. If the extracted gas is explosive, liquid ring vacuum pump should be selected and equipped with explosion-proof motor, because the whole working process of liquid ring vacuum pump is isothermal.

2. Requirements of vacuum equipment or parts for oil pollution. if the equipment is strictly required for oil free, all kinds of non oil pumps, such as liquid ring vacuum pump, molecular sieve adsorption pump, sputtering ion pump and cryogenic pump, should be selected. if the requirements are not strict, oil pumps can be selected, and some oil pollution prevention measures, such as cold trap, baffle and oil trap, can also be achieved.

3. how does the oil vapor discharged from the vacuum pump affect the environment? if the environment is not allowed to be contaminated, an oil-free vacuum pump, such as a liquid ring vacuum pump or an oil vapor, can be selected.

4. If there are several large liquid ring vacuum pumps working at the same time, the circulating liquid should be cooled, otherwise the vacuum degree will be affected. The cooling device can be equipped with a cooling tower and a booster pump to pressurize the pipeline.

5. The working pressure of the vacuum pump shall meet the requirements of the limit vacuum and working pressure of the vacuum equipment.

6. Under its working pressure, the vacuum pump shall be able to discharge all gas produced in the process of vacuum equipment.

7. Whether the vibration produced during the operation of vacuum pump affects the process and environment. If the environment is not allowed, the pump without vibration shall be selected or vibration reduction measures shall be taken.