How to select Rotary vane pump for vacuum forming ?

Vacuum forming is a kind of plastic processing technology. The main principle is to heat the flat plastic sheet and soften it, then use vacuum to adsorb it on the surface of the mold and form it after cooling.

The common vacuum forming method has concave mold vacuum forming and punch mold vacuum forming

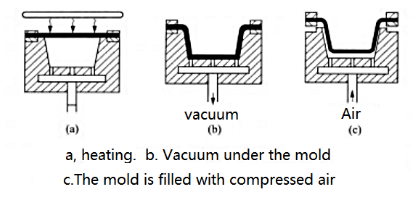

Concave mold vacuum forming

Concave mold vacuum forming is the most commonly used vacuum forming method, as shown in the figure. Fix and seal the area around the plate which is at the top of the cavity. the heater will heat the plate to softening state (a), then take out the air in the cavity to form a vacuum, make the plate under the atmospheric pressure against the mold and molding (b). When the plastic cooling finalize the design, and then from the bottom of the suction hole into the compressed air will be formed after the products blown out(c).

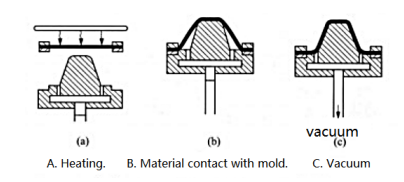

Punch mold vacuum forming

The plastic plate is clamped over the punch mold and heated until softened (a). Then moved down the clamp and the softened plastic plate is covered over the punch like a tent, that is, it is cooled and loses its thinning ability (b). Then taking out the air between the plate and the punch to form a vacuum,the edge of the plastic plate is attached to the punch and formed (c).

When it comes to rotary vane pump selection, generally only two parameters need to be known: the type&application of product and size.

According to these two parameters,we can select suitable vacuum pump!

As the core keyword of Vacuum forming, the vacuum pump provided by Shanghai EVP Vacuum can meet the needs of different models/different sizes of vacuum forming machine, Common vacuum pumps is:

SV Rotary vane vacuum pump, the ultimate vacuum is 50-200pa, and the capacity is 8m3/h-300m3/h.

EVP Vacuum has extensive experience in the vacuum forming industry, please feel free to communicate any question.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)