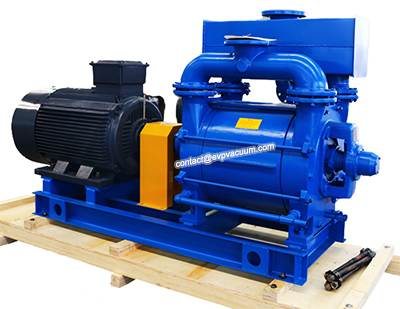

Liquid ring mechanical vacuum pump manual

1、 This paper describes the improvement of the complete set of Liquid ring vacuum pump (hereinafter referred to as the complete set of device), which has the characteristics of safe operation, compact structure, high degree of automation and remarkable energy saving effect. It is suitable for the gas medium without solid particles in the vacuum system, especially for the extraction process with a large amount of steam overflowing. If it is used for the vacuum extraction of the condenser in the power station, good results can be obtained.

2、 Liquid ring vacuum pump structure description and working principle

The complete set of equipment is composed of Liquid ring vacuum pump, water supply and cooling circulation part, air inlet and exhaust control part and transmission part.

1. The air inlet pipe is equipped with a pneumatic butterfly valve (5), which is controlled by a differential pressure switch (14). The differential pressure of the differential pressure switch (14) is generally adjusted at 2-3kpa. When the pressure difference before and after the valve reaches 2-3kpa (that is, the absolute suction pressure of the Liquid ring vacuum pump is 2-3kpa lower than the absolute pressure of the pumped system), the valve is opened and the gas in the pumped system is pumped. When the pump is stopped, the valve is closed to prevent the air from flowing back into the pumped system. (Note: the pneumatic butterfly valve of the unit is double acting. Pressure gas is required for opening and closing. When the air source is lost, the valve plate stays in the original position).

The pressure value set by the pressure switch (16) can control the stop and start of the pump. So as to realize the operation of multiple parallel pumps and the automatic control of standby pumps. The pressure value of pressure switch (16) can be set by the user according to the specific requirements of the pumped system.

2. When the pump is working, the extracted gas and part of the working water enter the gas-water separator (3) through the exhaust tee of the pump. After the gas and water are separated, they are discharged through the check valve (6). The gas can be discharged directly indoors or outdoors through the pipeline, but the diameter of the pipeline shall not be less than the diameter of the check valve (6), and the pipeline shall be as short as possible, otherwise the exhaust resistance will be increased and the performance of the pump will be affected.

3. When the Liquid ring vacuum pump works (forming water ring), it needs working water. The compressed heat of the gas generated in the operation of the pump and the heat of the steam in the mixed gas inhaled by the pump are absorbed by the working water, which is continuously discharged from the outlet of the pump to the gas-water separator together with the extracted gas. After being separated by the gas-water separator, the working water enters the pipeline, which is cooled by the heat exchanger (4). The working water enters the water ring pump again from the pipeline to form a water supply cycle. The water quality of the cooling water of the heat exchanger shall be clean, the water pressure shall be less than 1MPa (generally 0.3 ~ 0.6MPa ABS), and the water temperature shall be as low as possible.

4. The working water and make-up water required by the Liquid ring vacuum pump enter from the interface n3.3, and the make-up water pressure of the pump should be kept at 0.15 ~ 0.3MPa ABS during operation (if the water source comes from the condensate system and the pressure is large, the pressure relief valve should be used to reduce the pressure. When the unit is provided to the user, the pressure relief valve and filter have been equipped, which must be installed on the interface n3.3 pipeline before the pressure relief valve) 。 The low water level controller (24) keeps the water level above the lowest level. The high water level controller (high water level overflow pipe) (23) is used to limit the maximum water level, and excess water is discharged from n4.6. The water level of the gas water separator is indicated by the level gauge (9). Clean soft water shall be used as far as possible for the working water and make-up water of Liquid ring vacuum pump.

5. The suction port of the pump is equipped with a spray device. Part of the working water is introduced from the water supply pipeline, and the water is sprayed in the suction port of the pump through the nozzle (22), which can reduce the temperature of the extracted gas and condense part of the water vapor.

3、 Installation of complete plant

1. Use the four lifting holes (lifting lugs) on the base to lift, and do not use their pipelines or any other points to lift. When lifting and lowering, avoid too fast.

2. The complete unit shall be installed on the concrete foundation, and the weight of the unit shall be considered for the concrete foundation. The allowable error of concrete foundation surface is ± 1mm.

3. Use the sizing block to adjust the installation levelness of the complete device and tighten the foundation bolts. Since the pump and motor may be out of alignment during transportation, the position of the pump and motor on the base shall be readjusted. The installation of coupling shall conform to the following requirements: when there is no relative radial displacement between two axes, the relative angular displacement is allowed to be 30 ‘; when there is no relative angular displacement between two axes, the relative radial displacement is allowed to be 0.4mm.

4. All pipeline threaded connections and flange connections shall be inspected to ensure their tightness. When the complete set of equipment is connected with other systems, the additional stress on the equipment caused by the support and suspension of its pipeline and flange shall be avoided.

5. External vibration, such as vibration from other equipment, will affect the device. If the impact is serious, it should be considered.