Liquid ring vacuum pump knowledge

2BV series liquid ring vacuum pump is suitable for pumping out gas and water vapor. The suction pressure can reach 3.3kpa absolute pressure (97% vacuum pump). When transformer oil is used as working fluid (called oil ring vacuum pump), suction pressure can reach 670pa absolute pressure (99.3% vacuum pump), which can completely replace reciprocating vacuum pump. When the suction pressure of the vacuum pump is close to the limit vacuum for a long time, the cavitation protection pipe should be connected to protect the vacuum pump. When used as a compressor, the maximum pressure is 0.26mpa (absolute pressure). As a new energy-saving product, 2BV series liquid ring vacuum pump will replace the same energy vacuum pump with excellent performance and many advantages.

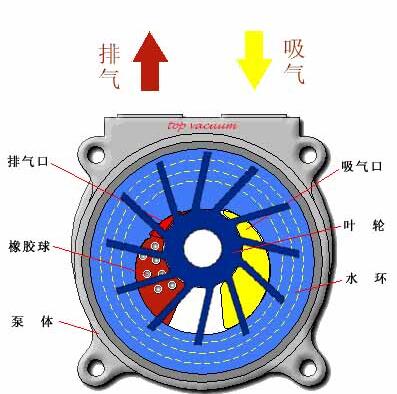

liquid ring vacuum pump structure characteristics and working principle

1. Liquid ring vacuum pumps are all driven by direct motor connection

2. Working principle: (from the driving direction)

As shown in the figure: the pump body is filled with appropriate amount of water as working fluid. When the impeller rotates clockwise as shown in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring of approximately equal thickness, which is determined by the shape of the pump cavity. The inner surface of the lower part of the water ring is just tangent to the impeller hub, and the inner surface of the upper part of the water ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the water ring). At this time, a crescent shaped space is formed between the impeller hub and the inner interface of the water ring, and this space is divided into several small cavities equal to the number of blades by the impeller blades. If the starting point is 0 ° at the lower part of the impeller, the volume of the small cavity will increase from small to large when the impeller is 180 ° before rotation, and the small cavity is connected with the suction port on the end face, at this time, the gas will be inhaled, and the small cavity will be isolated with the suction port when the suction is finished; when the impeller continues to rotate, the small cavity will change from large to small, so that the gas will be compressed; when the small cavity is connected with the exhaust port, the gas will be discharged out of the pump.

To sum up, the liquid ring vacuum pump realizes suction, compression and exhaust by the change of pump cavity volume, so it belongs to variable volume vacuum pump

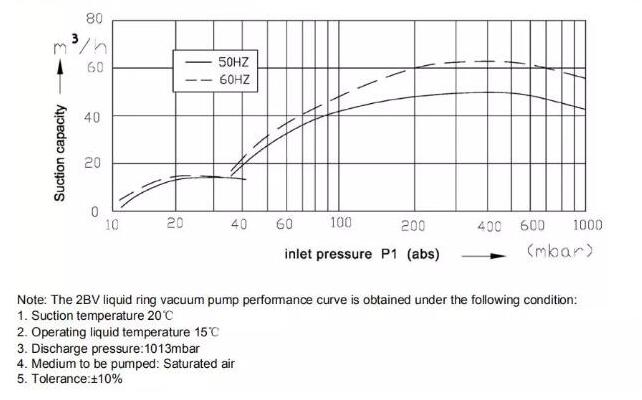

Performance curve of liquid ring vacuum pump (2BV Series)

liquid ring vacuum pump operation method

1. Start of liquid ring vacuum pump:

Before the long-term stop of the liquid ring vacuum pump, the pump must be turned several times by hand to confirm that there is no jamming or other damage in the liquid ring vacuum pump.

The liquid ring vacuum pump shall be started in the following order:

(1) Open the exhaust valve.

(2) Start the motor (pay attention to the positive and negative rotation of the motor)

(3) Open the water supply pipe quickly. Gradually increase the water supply until the water supply meets the specified requirements (pay attention not to run the vacuum pump dry).

2. Stop the liquid ring vacuum pump:

Stop the liquid ring vacuum pump in the following order:

(1) (if the air inlet pipe has a valve) close the valve on the air inlet pipe.

(2) Close the water supply pipe and shut down the vacuum pump quickly.

(3) After shutdown, the water in the vacuum pump cavity shall be drained to prevent the blade and pump shaft from breaking when starting again.

liquid ring vacuum pump routine maintenance :

1. In order to avoid wearing the impeller, vacuum pump body or jamming the impeller, the dust particles entering the pump cavity with gas and working fluid can be washed away through the flushing port at the bottom of 2BV liquid ring vacuum pump.

2. If hard water is used as working fluid, it shall be softened or the pump shall be cleaned with solution within a certain period.

3. The normal working bearing of the motor is 15 ℃ ~ 20 ℃ higher than the surrounding temperature, and the maximum temperature is not allowed to exceed 55 ℃ ~ 60 ℃. The normal working bearing shall be filled with oil 1-2 times a year, cleaned at least once a year, and all lubricating oil shall be replaced.

4. In case of leakage of the mechanical seal adopted by the water ring, check whether the dynamic and static rings of the mechanical seal have been damaged, or the sealing ring has aged. If the above situation occurs, new parts shall be replaced.

Compared with other mechanical vacuum pumps, liquid ring vacuum pump has the following advantages:

1. The structure is simple, the manufacturing accuracy is not high, and it is easy to process.

2. Compact structure, high revolution of vacuum pump, direct connection with motor in general, no reduction device. Therefore, with a small structure size, a large exhaust volume can be obtained, and the floor area is also small.

3. The compressed gas is basically isothermal, i.e. the temperature change of the compressed gas process is very small.

4. Because there is no metal friction surface in the vacuum pump cavity, there is no need to lubricate the pump, and the wear is very small. The seal between the rotating part and the fixed part can be directly completed by the water seal.

5. The suction is even, the work is stable and reliable, the operation is simple, and the maintenance is convenient.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)