Liquid ring vacuum pump maintenance skills

Liquid ring vacuum pump (referred to as water ring vacuum pump) is a kind of crude vacuum pump, which is used in many processes of petroleum, chemical industry, machinery, mining, light industry, papermaking, power, metallurgy, medicine, food and other industries as well as municipal and agricultural sectors

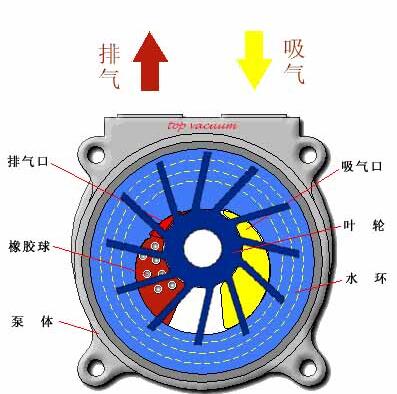

liquid ring vacuum pump working principle:

A proper amount of water is filled in the vacuum pump body as working fluid. When the impeller rotates clockwise according to the direction indicated in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring of approximately equal thickness, which is determined by the shape of the pump cavity. The inner surface of the upper part of the water ring is just tangent to the impeller hub, and the inner surface of the lower part of the water ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the water ring). At this time, a crescent space is formed between the impeller hub and the water ring, and this space is divided into several small cavities with equal number of blades by the impeller.

If the upper 0 ° of the impeller is taken as the starting point, the volume of the small cavity will increase from small to large when the impeller is 180 ° before rotation, and it is connected with the suction port on the end face. At this time, the gas will be inhaled, and when the suction is finished, the small cavity will be isolated from the suction port; when the impeller continues to rotate, the small cavity will change from large to small, so that the gas will be compressed; when the small cavity is connected with the exhaust port, the gas will be discharged out of the pump. To sum up, the liquid ring vacuum pump realizes suction, compression and exhaust by the change of pump cavity volume, so it belongs to variable volume vacuum pump.

liquid ring vacuum pump maintenance skills:

liquid ring vacuum pump local maintenance

Generally, it is arranged to be carried out in a planned way during the operation gap or winter maintenance period. The items of local maintenance mainly include:

1. Inspection and treatment of the copper sleeve and oil sleeve of the regulator of the full regulating liquid ring vacuum pump.

2. Inspection of guide bearing of vacuum pump. Check, record and handle the wearing condition, water leakage and journal wear of rubber bearing. Most of the oil guide bearings are Babbitt alloy steel bearings, which are soft and easy to wear. For example, the sealing effect is not good, the oil basin is shut down for water inflow, sediment deposition, and the bearing and journal are worn during operation. Especially for the carbon steel journal which is not plated or inlaid with stainless steel, in order to understand its corrosion and wear, it should be checked and treated regularly.

3. Inspection and inspection of thermometer, instrument, relay protection device, etc.

4. Oil groove position of upper and lower guide bearings and turbine oil sampling test.

5. Inspection for bearing clearance and bearing surface. According to the temperature of thermometer during operation, it is purposeful to check the clearance between bearing shells and the condition of shaft surface.

6. Check and handle the brake part.

7. Whether fasteners of all parts of the unit, such as foundation bolts, shaft keys and locating pins, are loose.

8. Check the appearance of the oil cooler and pass the water test to see if there is any leakage.

9. Check the cavitation and sediment abrasion of impeller, blade and impeller shell, and measure and record the degree.

10. Measure the clearance between blade and impeller housing.

liquid ring vacuum pump unit overhaul:

This is a planned management work to recover the technical condition of liquid ring vacuum pump unit through overhaul.

First, the accident damage, the probability of occurrence is very small.

The second is normal damage, such as friction wear, cavitation damage, sediment wear, vibration caused by various interferences, the effect and corrosion of AC stress, aging of electrical insulation, etc., or serious wear and damage of parts and components, resulting in serious decline of unit performance and technical and economic indicators, so the whole machine must be disassembled, repaired, replaced, adjusted and partially reconstructed.

The liquid ring vacuum pump also needs to be checked regularly to ensure the normal operation of the equipment. When using, make sure that these maintenance items have been checked.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)