Liquid ring vacuum pump sucks the phenomenon of abrasion containing micro particles

How to solve the wear phenomenon of micro particles in liquid ring vacuum pump

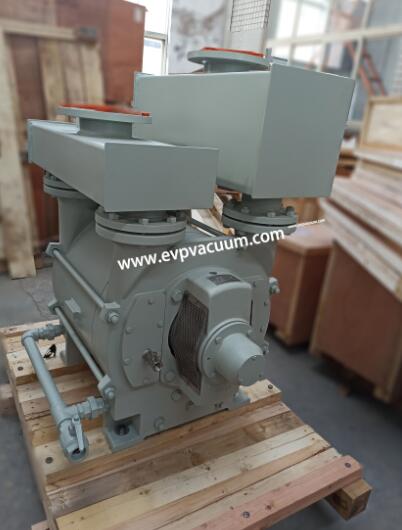

Due to the universality of liquid ring vacuum pump, liquid ring vacuum pump is also widely used in the application of pumping dust or conveying dust. Dust transport, especially the use of liquid ring vacuum pump in fine sand, will seriously reduce the service life of liquid ring vacuum pump under direct delivery condition. Yes, the ordinary service life of liquid ring vacuum pump is between one and three months, which is very short; At the same time, it also leads to the high cost of using liquid ring vacuum pump, and its short life is worrying. Therefore, it is believed that the material problem of liquid ring vacuum pump must be the poor quality of liquid ring vacuum pump, which leads to such a short life. The real fact is equivalent to grinding the internal parts of liquid ring vacuum pump with fine sand, which leads to the wear of internal parts. So how to deal with the wear phenomenon of micro particles in liquid ring vacuum pump?

1. The bag filter is set in front of the liquid ring vacuum pump. Its characteristics are simple; defects: easy to consume and need to be changed frequently.

2. Special dust filter is installed in front of liquid ring vacuum pump, such as the dust filter specially designed and consumed by Vacuum Pump Factory Co., Ltd. for dust filtration, its characteristics are: no maintenance and durable; defect: not suitable for dust filtration which reacts with water.

3. Water curtain filtration is set in front of liquid ring vacuum pump. Its characteristics are: suitable for large-scale air pumping project and dust dissolved in liquid.

No matter which method is used, in order to ensure that the liquid ring vacuum pump can work normally and efficiently, the gas must be cleaned and filtered before the liquid ring vacuum pump when it needs to pump or deliver the carrier containing dust or fine sand.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)