liquid ring vacuum pumps for de-oxygen membrane system

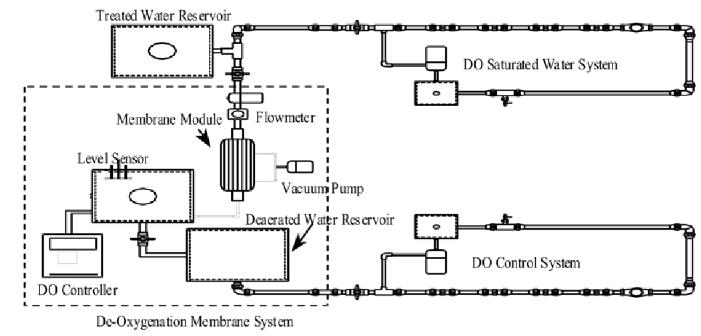

What is deoxidation membrane system

The deamination membrane technology can replace the traditional vacuum degassing device + intermediate water tank. Due to the substantial increase of the removal rate, it not only saves the cost of adding alkali, improves the effluent quality, but also greatly reduces the height of the device (the maximum height of the equipment needs 4.5 m by adopting the degassing tower, and the maximum height of the equipment after adopting the degassing membrane is reduced to about 2 m), and the floor area is also greatly reduced.

Principle of ammonia nitrogen removal from wastewater by membrane process:

NH4 + OH – → NH3 + H2O is an ionization equilibrium in water. With the increase of pH value of ammonia nitrogen wastewater, under certain temperature and pressure, ammonia nitrogen in wastewater will be decomposed into gaseous ammonia until the ionization equilibrium is reached. After the wastewater containing ammonia nitrogen enters into the special membrane module for ammonia nitrogen removal, the gaseous ammonia will react with the acid absorption solution outside the membrane through the micropores of hydrophobic membrane filaments to further absorb the ammonia nitrogen in the wastewater until the ionization equilibrium is reached.

The vacuum pump in the factory will volatilize part of the waste gas. In fact, the liquid ring vacuum pump itself will not produce exhaust gas. The exhaust gas discharged from the vacuum pump is mainly the gas component used in the working system. How to deal with this part of waste gas is simple, direct and low investment. Collecting and purifying discharge is carbon adsorption. The adsorption characteristics of activated carbon can be used to adsorb harmful components, so as to achieve good air purification effect.

The exhaust gas produced by the vacuum pump is not the only one. These two methods are used to make the organic waste gas collected and purified by the equipment, and then discharged into the atmosphere through a 15 meter chimney.

1. Carbon adsorption method: mainly composed of activated carbon layer and support layer. Activated carbon has pore space, large specific surface area and strong adsorption capacity. It is because of the characteristics of this activated carbon, it is widely used in advanced treatment of water, such as domestic water, advanced treatment of later water (clean water). After using activated carbon for a period of time, it will absorb a large amount of adsorbate, gradually become saturated, lose working capacity, and even seep into the filter layer. Therefore, activated carbon should be regenerated or replaced.

2. Ion purification method: a high-temperature generator is used to form a low-temperature plasma. Under the action of a large number of electrons with an average energy of about 5ev, organic waste gas molecules such as benzene and toluene are converted into various active particles and air through xylene of the purifier. CO2 is combined to produce low molecular harmless substances, such as H2O and CO2, to purify the waste gas. In this process, when the organic gas enters the cold ion reaction chamber, the gas is evenly distributed to the plasma reaction chamber (PRC). The reaction chamber was divided into 149 hexagonal tubes, each tube with a coronal line in the center and separated from the reaction chamber.

The high pressure line is used to guide the reaction chamber to regulate the high pressure, and the high pressure is conducted to the tubular line in the pipe. Discharge occurs from the wire to the pipe wall. Once discharged, the plasma electrons collide with gas molecules to produce chemically active nuclides, which are usually called free radicals and load carriers. In addition, it also has the function of micro electrostatic precipitator, which can remove dust.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)