Molecular vacuum pump for glass coating

Molecular vacuum pump for glass processing and coating

With the continuous increase in the application range and application heat of glass, people’s requirements for the appearance, oxidation resistance, acid and alkali resistance, and UV resistance of glass have gradually increased. Therefore, glass coating technology has emerged as the times require. The coated glass has the advantages of preventing surface oxidation, corrosion resistance, easy cleaning and scratch resistance.

After processing, the glass will be transported to the coating room for coating. Before coating, in order to ensure the compactness of the glass during coating, the coating room is usually vacuumed. The vacuuming process in the coating room is usually completed by a vacuum molecular pump.

Molecular vacuum pump

Development of FB400/4000 High Pumping Speed Molecular Pump

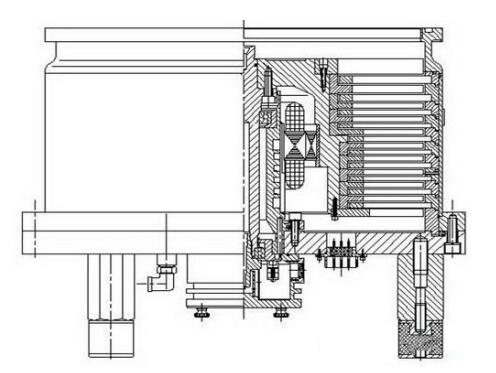

The development of modern technology and industry requires turbomolecular pumps with high pumping speed. Under this background, the FB400/4000 molecular pump with the largest pumping speed in China was successfully designed and developed.

1.Design of molecular vacuum pump

Compared with the international advanced level,molecular pumps made in china have a lower speed, so the pumping speed and H2 compression are relatively low. The problem that the replacement bearings of large molecular pumps must be reversed to the manufacturer that is cumbersome to the user.

A unique outer rotor motor is used in the design of the FB400/4000 molecular pump. Its biggest advantage is that all rotating parts of the pump (except the oil pump) can not be disassembled when replacing the bearings, so there is no need to rebalance, so the bearings can be replaced at the user’s place.

To improve the pumping speed and compression ratio performance of the pump. In addition to the blade angle change, the impeller at the entrance is thick and the number of blades is small to increase the suction area. The compression stage blades achieve optical sealing and increase the compression ratio of the gas. These requirements can only be achieved by milling.

The life of the pump depends on the life of the bearing, and the life of the bearing depends on good lubrication. In order to ensure that the bearing is not damaged due to lack of oil, a liquid level sensor is installed in the oil sump.

2.Impeller strength

The pumping speed of the molecular pump depends on the diameter of the turbine. The angle and speed of the blade. Under the premise that the diameter of the turbine and the angle of the blades are determined, the speed will determine the pumping speed of the pump. The increase in speed is restricted by the strength of the impeller. During the development process, the material, shape and structure of the impeller were systematically studied:

Due to the single direction of the fiber structure caused by the rolling process of aluminum alloy sheet, its longitudinal tensile strength is good, and the transverse tensile strength is poor. The impeller made of this material is not suitable for withstanding the centrifugal force of high speed.

The fiber structure of aluminum alloy that has been forged multiple times is radial, which is most suitable for making high-speed impellers.

The most dangerous section of the impeller is on the inner ring, so the area of the inner ring should be increased. Making the inner ring of the impeller into convexs is a good solution to the problem.

3. Successfully developed the largest pumping speed molecular pump in China

Pumping speed: 4000L/S

Compression ratio:N2 108/H2 103

Ultimate pressure:

CF flange:10-8Pa

LF flange:10-6 Pa

Rotary speed: 16000rpm

Start time: <20min

Stop time: <40min

Dimensions: Φ500×400

The above parameters are for reference only. If you want to know the specific data, please contact us.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)