The advantages and disadvantages of rotary vane vacuum pump

Rotary vane vacuum pump in the industry now is more and more widely used, how to foster strengths and circumvent weaknesses, promote the competitiveness of the product. Need to know further the advantages and shortcomings of the product itself.

Vacuum pump suction mouth with coarse filter wire mesh.To prevent solid foreign dust suction pump cavity.Are installed in the oil separator efficient separation efficiency of oil and gas exhaust transition device.When the pump is stopped, the suction valve built into suction mouth pump and pump system isolation, and prevent oil on being back into the system.By air cooling pump.

The disadvantage of rotary vane vacuum pump

1, the efficiency is low, generally around 30%, better can amount to 50%.

2, vacuum degree is low, not only because this is limited by the structure design , but the more important is restricted by working liquid saturation vapour pressure.

3, use water as working fluid, the limit pressure can reach 2000 ~ 4000 pa. ues Oil as working fluid, the ultimate pressure can rearch to 130 pa.

The advantages of rotary vane vacuum pump

1, because of the rotary vane type vacuum pump in the gas compression is isothermal, then can the pumping flammable, explosive gas.Because there is no exhaust valve and the friction surface, therefore can be pumping gas with dust, non-condensable gas and water mixture.With these outstanding features, although its efficiency is low, is still widely used.

2, extraction rate: 0.43-560 m3 / min

3, the minimum suction pabs: 33-160 hpa

4, use the temperature: – 10 ℃ and 40 ℃

5, supporting power: 7.5 – 560 kw

6, over-current material: cast iron, stainless steel

Scope of application

Rotary vane vacuum pump is a kind of mechanical vacuum pump oil seal type, is one of the most basic vacuum to obtain equipment in vacuum technology.Rotary vane vacuum pumps can be pumping a dry gas in the sealed container, if have spirit town device, can also take in addition to a certain amount of non-condensable gas.But it is not suitable for containing too much oxygen, metal corrosive, the pump oil will react and gas containing dust particles.A single-stage rotary vane vacuum pumps and two stage vacuum pump.oil sealed rotary vane vacuum pumps can also be the backing pump of difusion pump , piston vacuum pump , turbo molecular pump etc.

1. The vacuum pump is suitable for the closed system of vacuum use.Such as vacuum packaging, vacuum forming, vacuum extraction.

2. The inlet pressure range: 100 Pa, Pa – 100000 is beyond the scope of work vacuum pump oil mist is vent will be produced.

3. The vacuum pump can not pumping water or other liquids.Can’t pumping of explosive, inflammable, high oxygen content, corrosive gases.

4. General supply not explosion-proof motor, such as explosion-proof or other special requirements when the motor must conform to the relevant standards.

Rotary vane vacuum pump product picture:

Product specifications:

| Model | Pump speed(m3/h) | Motor Power(KW) | Inlet Diam (inch) | Rotary speed(rpm) | Oil Capacity(L) | G.W(kg) | NoisedB (A) | Dimensions(mm) | |

| 50HZ | 60HZ | ||||||||

| SV-010 | 10 | 12 | 0.37 (3ph)0.55 (1ph) | G1/2 | 1400 | 0.5 | 20 | 64 | 405*253*210 |

| SV-020 | 20 | 24 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 20 | 64 | 405*253*210 |

| SV-025 | 25 | 30 | 0.75 (3ph)0.90 (1ph) | G1/2 | 2800 | 0.5 | 22 | 64 | 405*253*210 |

| SV-040 | 40 | 48 | 1.5 (3ph)2.2 (1ph) | G11/4 | 1400 | 1.0 | 50 | 67 | 660*300*270 |

| SV-063 | 63 | 75 | 2.2 | G11/4 | 1400 | 2.0 | 83 | 68 | 695*420*295 |

| SV-100 | 100 | 120 | 3.0 | G11/4 | 1400 | 2.0 | 87 | 72 | 735*420*295 |

| SV-160 | 160 | 192 | 4.0 | G2 | 1400 | 4.5 | 152 | 74 | 805*520*410 |

| SV-200 | 200 | 240 | 5.5 | G2 | 1400 | 4.5 | 159 | 76 | 825*520*410 |

| SV-250 | 250 | 300 | 7.5 | G2 | 1400 | 7.0 | 230 | 76 | 1000*550*410 |

| SV-300 | 300 | 360 | 7.5 | G2 | 1400 | 7.0 | 236 | 76 | 1200*550*410 |

| SV-630 | 630 | 750 | 15.0 | DN100 | 960 | 35 | 620 | 75 | 1630*1300*980 |

| SV-750 | 750 | 900 | 18.5 | DN100 | 1150 | 35 | 640 | 76 | 1630*1300*980 |

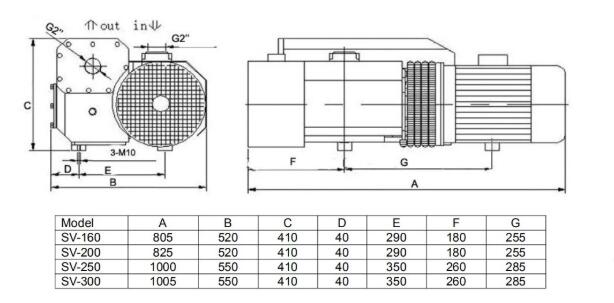

Installation size:

Application:

vacuum packaging, drying, distillation, concentration, loading and unloading, suction, vacuum forming, etc.

Our company also has two other rotary vane vacuum pumps, which are 2XZ direct drive rotary vane vacuum pump and 2x-a rotary vane vacuum pump:

Related videos

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)