Solution for Liquid Ring Vacuum Pump Working on Its Ultimate Pressure

Liquid ring vacuum pump can achieve 33mbar only, when the working vacuum is near to its ultimate vacuum, there will be cavitation. Simultaneously,liquid ring vacuum pump’s suction capacity decreased.

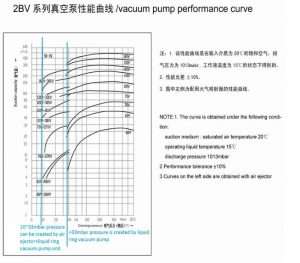

To solve this problem, user can add an air ejector on liquid ring vacuum pump’s suction port, which ensures the whole evacuating system a better suction performance and avoids cavitation on liquid ring vacuum pump chamber. Whilst, such pump unit can achieve a higher vacuum, around 20mbar. Hence when liquid ring vacuum pump is required to working under its ultimate pressure, it’s an ideal option to add an air ejector. The performance curve on below can be found the difference:

Followed is the introduction & working priciple of air ejector:

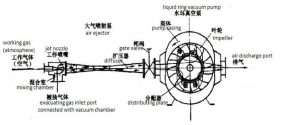

The air ejector equips a jet nozzle, mixing chamber,diffuser(see below). its discharge port connects with suction port of liquid ring vacuum pump.

Air ejector’s working principle: firstly start the water ring vacuum pump, so that the air ejector’s nozzle between the inlet and the exhaust port can form a pressure difference, the atmosphere entering the pump through nozzle, when the pressure difference meets 1/2 of 1atm(101325Pa), the air’s moving speed, through nozzle’s contracting section, is accelerated to reach the speed of sound at the throat, which can be further accelerated to remain the sound speed,and finally ejected to the diffuser to form a high-speed jet,causing the pressure in the suction chamber lower than the pressure in the vacuum vessel, hence the evacuated gas was sucked into pump chamber, when air and gas mixed in evacuating chamber,their momentun exchanged, then its air flow speed gradually slow down, which is reduced to less than sound speed at diffuser, and further decreased in diffuser expansion section. Meanwhile,the pressure continues to rise, and finally reached the exhaust pressure of the atmospheric injector–the suction pressure of the water ring pump.Then water ring vacuum pump sucks the gas and then discharges it to complete the suction and exhaust process.

EVP former system photo:

tags: liquid ring vacuum pump, air ejector

Edited by Shell Hu / EVP Vacuum Solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)