Roots and liquid ring vacuum system application in vacuum distillation

Vacuum distillation principle: with the help of the vacuum pump to reduce the pressure inside of system, then it can reduce the boiling point of liquid, some organic compounds can be distilled at a much lower than the normal boiling point temperature.

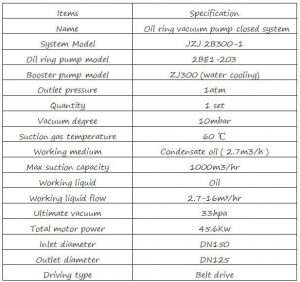

Part 1, The relevant parameters of roots liquid ring vacuum system:

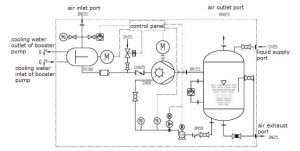

Part 2, The process and control of roots liquid ring vacuum system:

The process drawing of roots liquid ring vacuum system as follow:

The working fluid of the pump is Condensate oil, This pump mainly function is suction gas and steam under pressure that below the atmospheric pressure. During operation, the vacuum pump will suction condensate gas, air and steam which come from first stage vacuum, the gas will carry a part of liquid that working fluid from vacuum pump inside. The gas will arrived separator by exhaust pipes and then it will be gas-liquid separated in the separator. Some no-condensate gas is compressed to exhaust pressure, and condensate liquid will go in vacuum tower top tank when condensate liquid at the overflow level. In the separator, the working fluid (Condensate oil) be control the level, at the same time working fluid through the pipeline flow separator go in heat exchanger, then this work fluid will into the pump body after it change the heat with circulating water in heat exchanger.

Part 3, Roots liquid ring pump system application effect

In the refining process, the vacuum system of vacuum tower is the most important step. The vacuum degree’s keep and stable operation can directly affects the oil quality and yield.

(1)The advantages of roots liquid ring vacuum system

The roots liquid ring vacuum system have the high efficiency, energy saving, environmental protection, safety and stable characteristics.

<1>High efficiency, energy saving: Reducing the steam ejector stages and reducing steam consumption; Reducing the amount of cooling water and reducing the treatment of cooling water with pollution.

<2>Environmental protection: The liquid ring pump use the closed cycle system in this roots liquid ring vacuum system. Not only reducing the working fluid pollution, but also reducing the steam in contact with the medium.

<3>Safety and stable: vacuum system have the higher stability in tower top. It not be affected by steam pressure fluctuation, and it is also not sensitive to changes in volume of the entrance.

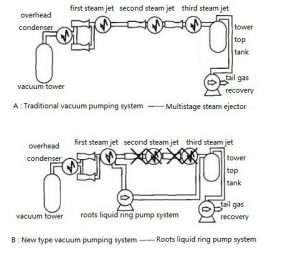

(2) Roots liquid ring vacuum system and traditional vacuum pumping system comparison

Traditional vacuum pumping system is picture A

Roots liquid ring vacuum system is picture B

It can be seen from the picture A and B that the traditional vacuum pumping process adopts multi-stages ejector, which has large steam consumption, and its vacuum degree is not easy to control. However, the roots liquid ring vacuum system has low steam consumption and it’s very easy to control vacuum degree.

Tags : Roots pump, Liquid ring pump, vacuum system

Edited by Jinny Zhang / EVP vacuum solution