Possible Questions and Solutions of 2XZ-C Rotary Vane Vacuum Pump

2XZ-C series of double-stage rotary vane vacuum pump is developed over years reaches by our special engineer team. The working process of 2XZ-C is: Rotor drives vanes to work in the surface of inside chamber, separate the inlet and outlet port and then drive gas out to create vacuum. 2XZ-C rotary vane vacuum pump can be used alone, and can also be used as backing pump and pre-pump of pumps with higher vacuum pressure.

For catalog of 2XZ-C, please check the link:

https://www.evpvacuum.com/p-en-77-2XZ_direct_drive_rotary_vane_vacuum_pump.html

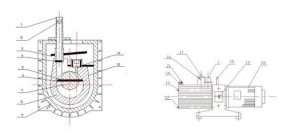

Below is the structural name and comparison chart of 2XZ-C for your reference:

1.Inlet port 2.Filter net 3.Oil baffle

4.“O”ring 5.Spring 6. Vane

7.Rotor 8.Stator 9.Oil box

10. Vacuum oil 11. Exhaust valve plate

12.Screw plug for oil drain 13.Oil glass

14.Screw plug for oil filling 15.Gas-ballast valve

16. Mist arrester 17.Outlet port 18.Handle

19.Driving bushing 20.Protective covers

In the use of 2XZ-C series double stage rotary vane vacuum pump, bellow are possible and normal problems, hope you can check and solve according to our advice:

1. Failures to obtain the specified ultimate vacuum pressure:

(1)The oil is not enough in 2XZ-C (oil-lubricated type), please fill in more clean oil. Note that you’d better check the quantity of oil by view port before operation, 4/5 will be the suitable quantity.

(2)The failure may be due to the contamination of the oil by vapor, please widely open the gas-ballast valve to purify the oil or renew the oil.

(3)Air leak at the joint of pipe, pipe itself and vessel, take measure to eliminate the leak.

(4)Improperly placing of the rubber seals of the inlet pipe or gas ballast valve or deterioration of them readjustment or replacement of them should be made.

(5)Clogging of the oil holes, drain oil, dismount the oil box, clear the oil holes.

(6)The vacuum system, including vessel and pipe, is seriously contaminated. Please adjust and check.

(7)Overheating of the pump, it causes not only the drop of viscosity of the oil and rising of the saturated vapor pressure of the oil but also causes the cracking of oil, improve ventilation and cooling to decrease ambient temperature. If the temperature of gas pumped is too high, it should be cooled before sucked by the pump.

2. Oil splash

Check the oil level, whether it is too high. Are there any oil or impurities to clog the oil separator. The oil baffle is right positioned and firmly fixed.

3. Oil leakage

Check the oil plug, sight glass and oil box shim. Replace them if necessary.

The oil leakage many develop at the joint of pump and frame or shaft seal. Readjust or replace them if necessary.

4. Noise

The noise may be caused by breaking of vanes, too much oil, worn out of bearing deterioration of parts. Check them an readjust or replace them if necessary.

5. Such back of oil

(1)Oil check valve can not tightly close, oil level drops, fast after pump stops. Check the variation of oil level by starting and stopping the pump again and again.

(2)Oil seals in two cover plates are improperly placed or worn out. Replace them.

(3)The exhaust valve plate is worn out. A new plate is replaced.

(4) In the use of 2XZ-C, if customers have any questions, please feel free to contact EVP team. And please enclose real pictures of the working condition and explain problems clearly, so that we can better solve your problems.

Tags: rotary vane vacuum pump, sliding vane vacuum pump, pump questions

Edited by Emily Fu / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)