Oil free claw vacuum pump in semiconductor industry

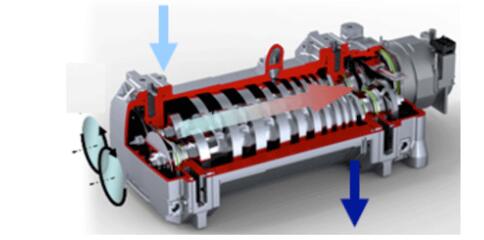

Oil free claw vacuum pump uses claw rotation principle to work. Dry compression, no contact, no wear. Two claw rotors rotate in opposite directions in the pump cylinder to guide and compress the gas medium. This shape of the rotor keeps the tip of the claw and the wall of the pump cylinder, as well as the adjacent claw surface, small and accurate measurement clearance. The claw rotor rotates continuously, which makes the gas be inhaled, compressed and discharged under pressure.

The two claw rotors of the oil-free claw vacuum pump rotate in opposite directions in the cylinder body. The air and process gas are compressed and discharged after being inhaled by the claw rotor. The claw type rotors will not contact with each other or with the cylinder block where they operate. The tight clearance between the claw rotor and the cylinder block not only optimizes its sealing performance, but also ensures the continuous high pumping speed. The synchronous gear ensures the accurate synchronous operation of the rotor. The oil-free claw vacuum pump is directly driven by a flange connected asynchronous motor, and the motor energy efficiency grade is IE2 / ie3.

Oil free claw vacuum pump is developed for the development of semiconductor industry. It has the following advantages and features:

1) there is no lubricant in the pump cavity, so there is no oil return;

2) the extraction element is non-contact and can realize high-speed operation (3000r / min);

3) corrosion and wear resistance of the surface contacting with the extracted gas;

4) the air flow in the pump chamber moves vertically, and a small amount of particles and liquids are easy to be removed under the action of gravity;

5) the pump has various types and expandable functions. The main body of the pump is equipped with gear, motor and gas purification equipment. The accessories include anti backflow valve at the inlet, shut-off valve at the outlet, electrical monitoring and alarm device;

6) the lower bearing of gear and pump shaft is lubricated with PFPE oil, and the bearing in the upper end cover is lubricated with PFPE grease;

7) the second, third and fourth stages have purification gas inlets to improve the smooth passage of the pumped medium through the pump cavity. If there is no need for this, purification gas can not be connected. The purification gas is adjusted by three flow meters respectively, which are independent to each other, so as to save inert gas. Three electromagnetic valves can be used to fine tune its flow;

8) the inlet anti backflow valve can separate the pumped container from the pump chamber, and the outlet shut-off valve can seal the outlet of the pump, and connect the pump with purified gas. These valves can be opened and closed automatically. The good Kaide vacuum system has reliable protection, and the backflow to the vacuum chamber is eliminated;

9) electrical monitoring and operation, mainly including power supply, remote operation and on-off valve control.

When the oil-free claw vacuum pump fails, the pump can automatically stop, and the two valves are closed together or the shut-off valve is closed. Power and remote control have a transformer and rectifier to provide the required current and voltage to meet the needs of the monitoring process. The power supply and relay are used for the on-off and overload protection of motor. The operation process includes display, button control, control valve of motor, anti backflow valve and shut-off valve, on-off valve of the second, third and fourth stage purified gas, main valve of inert gas, valve for ventilation of purified gas to shaft seal, etc. In case of fault monitoring, alarm or shutdown, the system can be controlled automatically and by buttons. When starting, turn on the purified gas, the pump operates normally for 3min, the purified gas flows into each section, and the purified gas has some influence on the pump performance. In case of emergency, press the automatic stop button, the purified gas will continue to be connected, the inlet anti backflow valve will be closed, the pumps at all levels will be purified for 1min, the purification will be finished, the motor will stop again, and the inert gas stop valve will be closed.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)