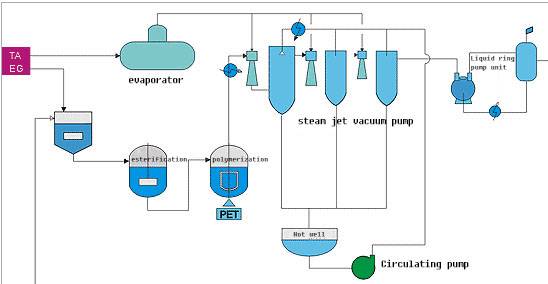

Polyester Chemical Fiber Steam Jet Vacuum Pump

roduct Introduction:

Vacuum ejector is the main equipment of the chemical fiber polyester vacuum system. The steam ejector is suitable for intermittent and continuous production of polyester and has been developed, and also has been matched with the polyester equipment of dozens of domestic and foreign enterprises, forming a complete model The series of steam ejectors.

Steam ejector series in chemical fiber polyester process

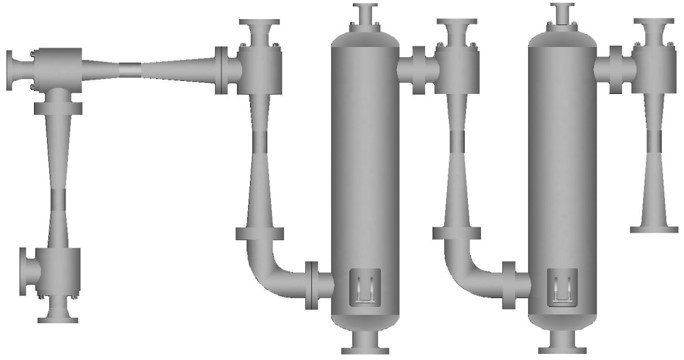

Five-stage steam ejector series

Five-stage water vapor jet vacuum pump: working vacuum degree: 0.0133~0.067KPa·A

Applications:

①Polyester polyester chips

②Slice thickening

③Fine chemical production

④Sublimation and drying of medicine

⑤Vacuum treatment of molten steel

⑥Metal smelting magnesium

⑦Flavor and fragrance

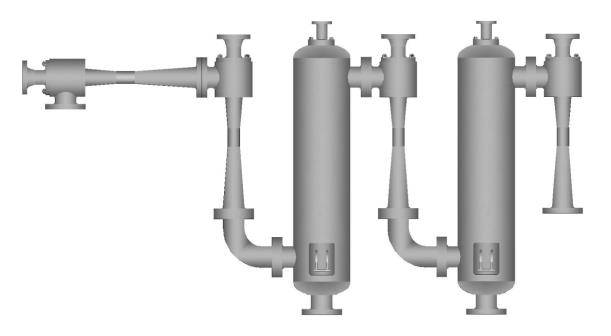

Four-stage steam ejector series

Four-stage steam jet vacuum pump: working vacuum degree: 0.133~0.67KPa·A

Applications:

①Fatty acid distillation

②Chemical monomer recovery

③Distillation of flavors and spices

④Deodorization of vegetable oils

⑤Chemical section drying

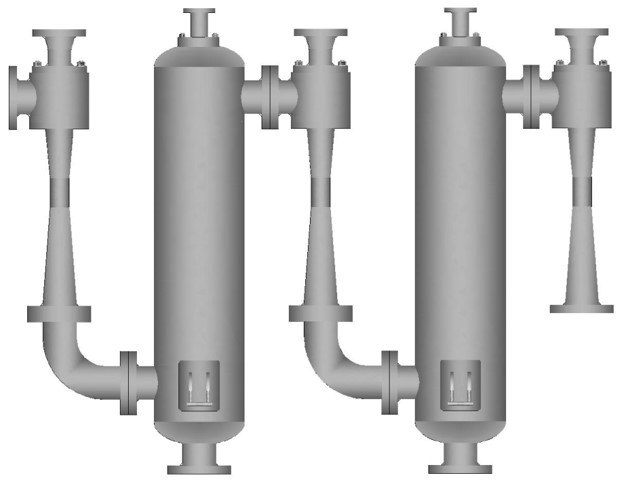

Three-stage steam ejector series

Three-stage steam jet vacuum pump: working vacuum degree: 0.67~3KPa·A

Applications:

①Viscose fiber vacuum deaeration

②Decolorization and deodorization of vegetable oil

③Vacuum impregnation

④Jet refrigeration

⑤Drying chemical fiber chips

⑥Chemical monomer recovery

⑦Vacuum regain of tobacco leaves

⑧Glycerin distillation

⑨Concentrated crystallization

Two-stage steam ejector series

Two-stage steam jet vacuum pump: working vacuum degree: 4~13KPa·A

Applications:

①Concentration and evaporation of compounds

②Vacuum concentration of inorganic salt and lye

③Desolubilization and dehydration of grease

④Phenyl anhydride, maleic anhydride, partial anhydride

Glycol steam ejector series for intermittent device in chemical fiber polyester process

In the polyester reaction of PTA, ethylene glycol medium is used as power to replace the steam jet pump to make the ethylene glycol medium recycled.

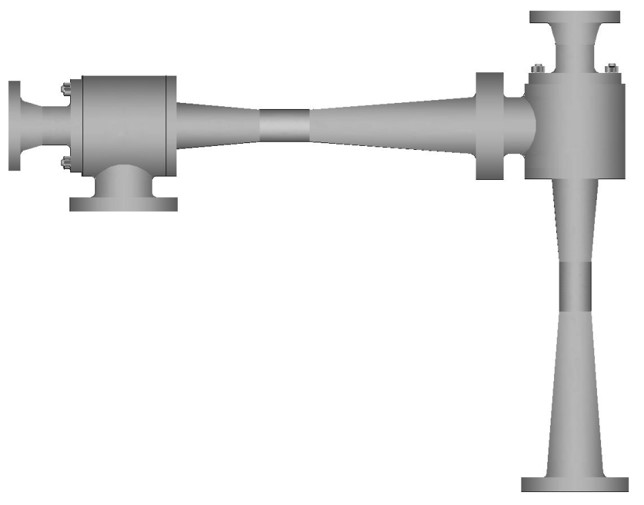

The ethylene glycol steam ejector is a new type of vacuum acquisition equipment developed to meet the high vacuum required for the polymerization of polyester chips. The power steam source of the ethylene glycol steam ejector is based on the heat source of the ethylene glycol steam generator as a high-temperature heat medium, and the power steam pressure is low. Use ethylene glycol as a cooling medium to cool them down, so as to achieve the closed loop use of ethylene glycol. It is a new type of energy-saving vacuum acquisition equipment.

Feature

- The vacuum is stable and the vacuum system will not be blocked

- All EG extracted from polycondensation is recycled

- The operating cost is low, 1/3 of the water vapor jet vacuum pump.

- No waste water

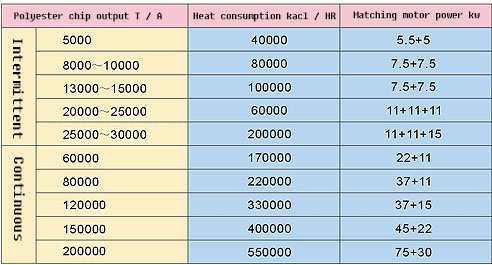

Glycol steam ejector series for intermittent equipment and continuous ethylene glycol steam ejector series

Energy consumption index

Basic process