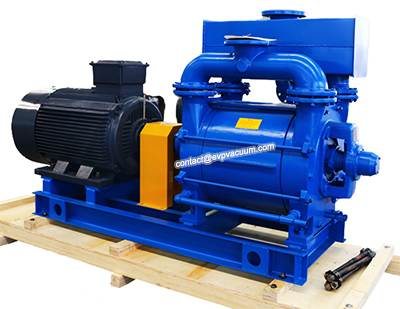

vacuum distillation water ring vacuum pump

Vacuum distillation separates the components of the mixture under reduced or high pressure. When vacuum distillation is carried out at a lower boiling point, the compound is separated from the compound mixture at a higher boiling point. In order to separate and recover valuable products, vacuum distillation is necessary for the following industries:

chemical plant

Petrifaction

Pharmaceutical industry

Fine chemical manufacturing

Bulk chemical manufacturing

General industry

The function of vacuum distillation is to extract and capture light hydrocarbon separated from crude oil, and avoid thermal degradation or decolorization of products. In addition, when the maximum temperature limit is applied, vacuum distillation reduces the operating cost, avoids the hydrocarbon chain broken due to overheating, reduces the adverse side effects and improves the product recovery.

EVP is a manufacturer of engineered vacuum solutions for vacuum distillation. Experienced application engineers ensure maximum efficiency and performance gains while optimizing custom processes, applications, and technical requirements. The vacuum system reduces greenhouse gas emissions and operating costs to the greatest extent, while improving system stability.

Fractionation and atmospheric distillation

Vacuum distillation is carried out under atmospheric conditions or vacuum. Distillation occurs when a liquid has a solid component or a liquid is a mixture of two components with different boiling points. There are two types of distillation: fractionation and atmospheric pressure.

In the process of liquid fractionation, the boiling point of the mixture is similar, so it can not be separated by simple distillation.

Atmospheric distillation occurs when the product is heated and distilled under atmospheric conditions. In this process, a lot of heat energy is needed. It is important not to reduce the quality or performance of products that require distillation.

Vacuum distillation towers are usually large, with a maximum diameter of 46 feet (14 m), a maximum height of 164 feet (50 m), and a feed rate of about 160000 barrels per day.

The vacuum distillation tower must provide good gas-liquid contact, while maintaining a low pressure increase from the top to the bottom of the tower. Therefore, the distillation tray is only used when the product is extracted from the side of the vacuum tower. Most towers use packing materials for gas-liquid contact because the pressure of this packing is lower than that of the distillation tray. Packaging materials can be structured sheet metal or randomly dumped packaging.

Absolute pressure is usually 10 to 40 mmHg absolute pressure achieved by using a multi-stage steam ejector or a combination of a steam ejector and a liquid ring vacuum pump.

The vacuum is realized by the whole steam injection system or the hybrid system combining the two vacuum technologies. By adding liquid ring vacuum pump and high vacuum capacity, the injector is more efficient, thus forming a hybrid power system.

2BV vacuum pump series is the best liquid ring vacuum pump. This series of vacuum pump is used for vacuumizing, which can achieve a discharge pressure of up to 1551 mmHg and can be used for differential pressure.

The vacuum hybrid system reduces greenhouse gas emissions and operating costs, while improving system stability. The hybrid system is innovative in design to improve efficiency, increase energy savings and provide reliable services.

Vacuum pump has been used in distillation for many years. These two-stage vacuum pumps have a simple and reliable design and are lubricated with new oil.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)