Pulp and paper-making machine use liquid ring vacuum pump

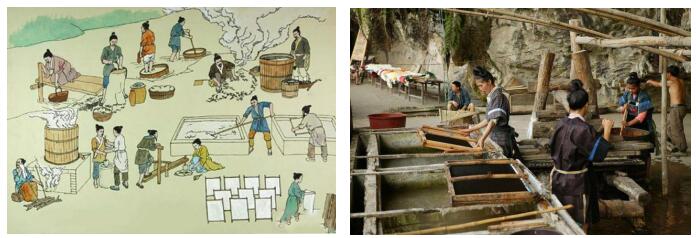

Paper-making is one of the four great inventions of ancient China. Paper is the accumulation of long-term experience and wisdom of the Chinese working people. It is an outstanding invention in the history of human civilization.

In the early days of paper-making, the materials were mainly bark and rags. More than 1800 years ago, Cai Lun, a great reformer of paper-making, made bark, hards, rags, and fishnets as raw materials. The traditional paper production process is putting the raw materials such as hemp, rags and so on to immerse, shred, wash, heat, rinse, pound and water mixed into a suspended slurry, remove the pulp, and dry to become paper.

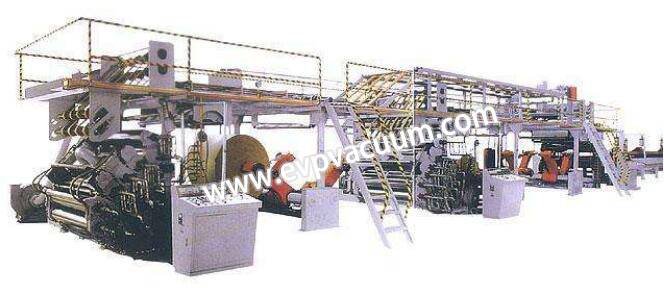

Today, the paper industry has become a major processing industry that provides commodity materials such as packaging, printing, and information industries, as well as a more competitive processing industry with a higher degree of marketization and nationalization. The development of the paper industry is closely related to the national economy and social development.

Throughout the paper production process, in the paper forming process to a number of processes to use vacuum dehydration and vacuum filtration of these process methods.To remove water from the pulp and filter impurities to form sheets of paper.

So, what is the vacuum dehydration and vacuum filtration process?

1.Black liquor evaporation

Black liquor evaporators in pulp mills are used to concentrate black liquor produced during the pulp cleaning process so that the liquid can be recycled in the recovery furnace for reuse in pulp production.

2.Coarse pulp washer

The pulp washer removes the pulp chemical (black liquor) from the paper material before bleaching or other material preparation. Coarse pulp washer is a typical horizontal drum filter.

The drum cavity creates a vacuum that causes the material to adhere to the outer surface of the drum as the drum rotates in the raw material slurry and helps to clean the black liquid from the material.

3.Lime mud filter

Lime mud filter in pulp mills are used to recover lime from the white water clarification process. Lime mud filter is a typical horizontal drum filter, similar to the coarse pulp washer. The inside of the drum can generate a vacuum as the drum rotates in the lime mud, the outer surface of the drum forms a lime cake. Then scrape it off and reuse it in the whitewater process.

4.Pulp sediments filter

In the pulp mill, the Pulp sediments filter is used to filter the unburned suspended particles in the “green liquor”, Sediment filter is a typical horizontal drum filter, the inside of the drum creates a vacuum, which is used to extract particles from the green liquid.

5.Vacuum dehydrator

Vacuum dehydrator is used to dehydrate the raw material during the preparation stage to increase the raw material concentration. The dehydrator is a typical horizontal drum filter used to dehydrate the pulp in proportion to increase the concentration of the raw material.

6.Raw material and white water degassing system

Raw material and white water degassing system are used in the raw material preparation phase, to remove air carried by raw material or air from diluted water. Raw material and white water degassing systems are important because to remove air from the paper, which can cause pinholes in the paper and have a significant impact on printing quality, mechanical properties and overall quality.

7.Suction box

The suction box is a static device that dewaters directly from the pulp on the forming section of the paper machine. The paper machine generally has 2-10 suction box, usually connected into a complete unit. Due to the large amount of dewatering, it is necessary to set a front separator between the suction box and the vacuum box. EVP liquid ring pump is used to produce the vacuum in the suction box.

8.Couch roller

The couch roller is an important dewatering part of the paper machine. The roller is stationary, with a rotating porous. The roller can have 1 or 2 vacuum zones.

9.Suction roller and carrying roller

The suction roller sucks the paper away from the mesh in the forming stage and guides it into the press section. Then, in the press section, the carrying roller transfers the paper from one cloth to another. None of these processes are officially dehydrated, but small amounts of water can be removed from the paper.

10.Suction press

Vacuum pressing uses mechanical means to squeeze water from paper. In the press section, rollers with granite and hard rubber surfaces are in close contact to form a “nip zone”. A typical paper machine may have 1-3 nip zone. When the paper passes through the nip, the moisture in it is squeezed out and penetrates into the press felt, and when the paper passes through the press section, these cloths is used as paper transportation means. In the dehydration process, the press section has vacuum and non-vacuum rollers.

In the entire Pulp manufacturing process, the choice of vacuum pump is particularly important. High quality vacuum pump can reduce the cost of paper making and improve the quality of paper during the forming process. So, how should the vacuum pump be selected in this process? The user can flexibly select the vacuum pump according to the required pumping volume/budget, etc.

The vacuum pump provided by Shanghai EVP Vacuum Technology Co., Ltd. can meet the needs of different models/different sizes of paper-making machines. Among the several vacuum pumps that are selling well are:

1.2BE liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 246m3/h-9450m3/h.

2.2BE3 liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 4200m3/h-62400m3/h

3.CL cone structure liquid ring vacuum pump, the ultimate vacuum are 80hpa-440hpa, and the gas volume is 1320m3/h-4980m3/h

For almost 25 years EVP has supplied the paper industry with high cost-effective vacuum pumps, compressors, and engineered systems for paper making and dehydration&filtration for paper machines. Our products require minimal maintenance and keep your process running smoothly, Even under the demanding conditions of the industry. We will continue to offer innovative solutions that further enhance reliability while increasing energy savings and profitability for your mill. Our reputation in the paper industry is popular and hard earned. The reason is simple – our liquid ring vacuum pumps and systems are proven to help your mill produce quality paper at a lower cost. Further proof that Smarter Works Harder.

Need reliable performance plus energy savings? You need EVP.

EVP Vacuum has extensive experience in the paper making industry, please feel free to communicate any questions.

Edited by: Oliver Pan

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)