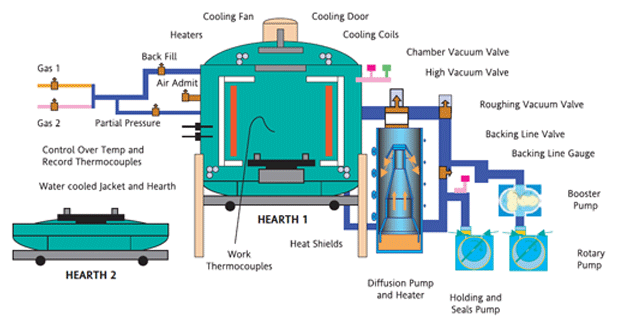

Vacuum Heat Treatment equipments vacuum pumps

Heat Treatment is the process in which metallic/steel parts are exposed completely or partially to time-temperature sequences in order to change the mechanical and/or corrosion properties. There are numerous application areas, e.g.:

• Annealing

• Hardening

• Tempering

• Aging

• Case hardening

In order to achieve a higher strength of the material, better wear resistance or to improve the corrosion behavior of the components, heat treatment vacuum furnace is needed.

All of these processes need a temperature up to 1.000 ℃ and higher as well as especially developed furnaces to achieve such ranges.

Oxidation occurs on the part’s surface when exposed to the atmosphere (air). This results in costly and time-consuming post treatments. Therefore, heat treatment is preferably conducted in an oxygen-free atmosphere. In addition to the use of high-purity protective gases, vacuum allows the best protection against oxidation, thus being the most cost-efficient atmosphere.

From Series Product to Individual Vacuum Solution

Vacuum heat treatment is the most economic, reliable and reproducible way of imparting characteristics to materials and surfaces. Compared to inert gas ovens it is cleaner – a vacuum contains far fewer contaminants than the best quality gas. Vacuum supply is thus both an important part of heat treatment processes and an indicator of high product quality. Here is a selection from the extensive EVP vacuum products range:

SV oil sealed rotary vane vacuum pumps

SV rotary vane vacuum pumps have a robust and proven oil-lubricated design and may be used as for pumps. They are air-cooled, and available in a wide range of sizes. They may be combined with Puma or Panda Roots vacuum pumps and are ideal for all fine vacuum applications.

EVP vacuum systems

EVP vacuum systems can be built with several types of pump, and always include a fore pump combined with a booster. The number of combinations of pump types and sizes is very large, permitting the operating pressure and throughput to be matched exactly to the heat treatment process.

K & KT Series oil diffusion vacuum pumps

Oil diffusion pumps deliver top performance for high vacuum applications. They have an innovative multi-stage jet design, and are ideal for large-scale heat treatment processes in which high vacuum levels must be achieved in the shortest possible time. Oil diffusion pumps are best used in a vacuum system that generates the required rough vacuum.

Turbo molecular vacuum pumps

Turbo vacuum pumps were developed specifically for industrial high vacuum applications at up to 1·10-10 hPa (mbar). They are used when high pumping speeds are required, and in cases where the evacuated gases must remain completely free of operating fluids.