Roots blower for textile printing and dyeing energy-saving dehydration

Roots Blower in Textile Printing and Dyeing Industry of Application

1.Roots blower vacuum continuous dehydration

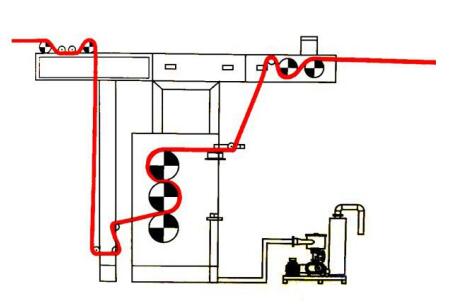

Mainly used for vacuum dehydration of fur, blankets and wool spinning. Installed on the rolling car, the fabric is pressed by the rollers and then sucked by the Roots blower vacuum, which can effectively prevent scratches on the fabric surface, greatly reduce the moisture content of the page, improve efficiency and reduce labor intensity.

2.Roots blower textile printing and dyeing wastewater treatment

Roots blower uses aeration and reoxygenation method to treat wastewater.

Roots Blower for Textile Printing and Dyeing of Characteristics

Roots blower for textile printing and dyeing is suitable for continuous open-width dewatering of strong pile fabrics, jacquard fabrics, silk fabrics, worsted fabrics, woolen fabrics, medium-wool wool-like fabrics, etc., effectively shortening the drying time of fabrics after dyeing and washing, and reduces Labor intensity improves production efficiency. The fabric after continuous vacuum dehydration using Roots blower is more uniform, which makes the subsequent addition of chemical additives more stable, thereby improving product quality.

Roots Blower for Textile Printing and Dyeing of Selection

Please select the appropriate parameters according to the required air volume and pressure and other parameters. Or call our hotline. Our customer service will help you solve problems.

Tips of Roots Blower:

What is the Roots blower safety valve?

Roots blower is composed of main machine, base, motor, motor seat rod, belt, pulley, belt guard, three-way, pressure relief valve, check valve, pressure gauge, inlet muffler, outlet muffler, shockproof joint, shockproof foot It is composed of pads, matching screws, etc.

Among them, the safety valve plays a very important role in the equipment. When used improperly, it may have some impact on the machine. So how should the safety valve be used and what should be paid attention to when using it?

1.Precautions for the use of Roots blower safety valve

Safety valves generally operate under low pressure, so the contact surface between the valve seat and the valve body is precisely machined. If foreign matter adheres to the valve seat, the foreign matter will be adsorbed to the contact surface when the valve body is working. , Thus forming a leak. In addition, please pay attention to check whether the safety valve is impacted during transportation, which is also the cause of leakage.

2.Setting method of safety valve of Roots blower

Principle: When the load exceeds the set pressure of the safety valve, the safety valve opens, thereby preventing the failure of the Roots blower.

Roots blower safety valve

Setting method:

① Start the Roots blower

② Observe the pressure gauge and tighten the gate valve so that the pressure exceeds about 10% of the set pressure.

③ Loosen the lock nut and turn the adjusting screw counterclockwise until the air is discharged from the safety valve.

④ If during the process of tightening the gate valve, the set pressure has not been reached and the safety valve has discharged air, please turn the adjusting screw clockwise again until the air is no longer discharged, and then turn it counterclockwise, just again. Until air is discharged (turn clockwise, the set pressure becomes higher; turn counterclockwise, the set pressure becomes lower.

⑤ Tighten the lock nut and adjusting screw.

⑥ Loosen the gate valve and reduce the pressure so that the safety valve no longer exhausts.

⑦ Check whether the safety valve is working under the set pressure, and tighten the gate valve again to increase the pressure.

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)