Vacuum pump in electronic semiconductor industry application

The electronics and semiconductor industries are revolutionizing our lives, enabling us to enjoy the pleasure and comfort of science and technology. Vacuum equipment plays an extremely important role in the production process of electronic products and semiconductor equipment. In view of the special production requirements, it is necessary to select suitable vacuum equipment. Vacuum products are mainly used in the following fields of electronics and semiconductors:

Electron accelerator, photoelectric device, electronic material, X-ray tube, crystal oscillator, relay, laser, ion implantation equipment, ion etcher, chemical vapor deposition equipment, physical vapor deposition equipment, molecular beam epitaxy equipment, integrated circuit packaging, other semiconductor application equipment.

After tracing back to the industry, dry screw vacuum pump can be divided into three categories: production vacuum (medium and high vacuum); cleaning vacuum (rough vacuum); process vacuum (rough vacuum). Different types of fields require different vacuum pumps.

Dry screw vacuum pump application

Vacuum for production mainly reduces the air in the working space and keeps the working space clean through high vacuum. The main types of vacuum pumps used include dry pump (dry screw vacuum pump, claw pump) and molecular pump and its units. The vacuum equipment used in production is larger in quantity and smaller in power per unit.

Cleaning vacuum mainly uses negative pressure and atmospheric pressure difference for liquid or particle removal or transportation. This kind of application mainly uses water ring pump and multi-stage centrifugal fan. Because of low vacuum, multi-stage centrifugal fan is more used. Vacuum source is a part of its system.

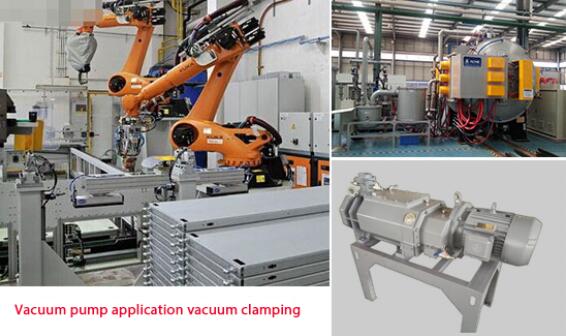

Process vacuum mainly uses negative pressure adsorption to carry or clamp workpieces. Dry pumps such as screw pumps, claw pumps, water ring pumps, rotary vane pumps and micro-oil screw pumps are common vacuum equipment in process vacuum.

Dry screw vacuum pump manufacturer EVP has core host manufacturing technology, first-class processing and testing platform, to provide you with efficient, stable, energy-saving and environmental protection of air compressor products.

Rotary vane vacuum pump application

The characteristics of rotary vane vacuum pump are as follows:

1. practical ultra low noise

Over the years, continuous efforts have been made to control the noise of rotary vane vacuum pumps.

The world’s advanced low noise design and precision processing, seamless assembly, from the page to the industry known for low noise.

2. safety and cost saving

Rotary vane vacuum pump with its core technology of excellence, whether intermittent use or all-weather continuous non-stop operation, Rotary vane vacuum pump, the guardian of your equipment, your choice of trust!

3. strong and durable

Rotary vane vacuum pump adopts high compact design, with strong durability, stable high vacuum, strong drainage steam capacity, continuous operation in full pressure range and other characteristics!

In order to meet the rapidly changing needs of customers in the electronics and semiconductor industries, Dongguan Punock Vacuum Technology Co., Ltd. has been continuously shortening the product development cycle, introducing new products more rapidly, and significantly improving the quality of service. Our communication with customers has never been like today. This is important.

We can bring it to you:

1. cost-effective products based on the design of the pump body.

2. efficient and practical based on robust industrial design.

3. one-stop on-site online service

If you are interested in EVP vacuum pump products or want more information, please leave a message for consultation or email contact@evpvacuum.com.