Steam jet vacuum pump in magnesium smelting industry

New high efficiency three stage steam jet vacuum pump in magnesium industry of application

1. Introduction:

In the past, China used a slide valve Root mechanical vacuum pump unit for vacuum magnesium smelting. Each reduction furnace should have two ZJ600/H500 mechanical vacuum pumps, and each motor has a power of 22.5 kilowatts. With an annual output of 1000 tons of magnesium, there are 5 ~ 6 reduction furnaces, and 10 ~ 12 mechanical vacuum pumps need to consume 270 kilowatts per hour. In recent years, magnesium smelting industry continued to large-scale development, annual output of 10000 tons, 30000 tons, 50000 tons of magnesium smelting enterprises, in order to save power consumption, reduce the enterprise cost, begin from 1995, multi-stage steam jet vacuum pump into the magnesium smelting industry, instead of mechanical vacuum pump unit, after years of use, continuously improve and perfect, adjustment, has obtained the good application effect, especially using the reduction furnace using high temperature flue gas waste heat boiler to produce steam supply steam jet vacuum pump is used, the more embodies the superiority of steam jet vacuum pump, to reduce the enterprise cost, Reduce the one-time investment and operation cost (particularly pronounced for mechanical energy saving effects of vacuum unit, has been refined magnesium industry recognized, this article no longer narrative), improve the stability and reliability of the vacuum degree is more outstanding, has obtained the magnesium smelting industry consensus, new ShangChang after 2001 and the expansion of enterprise scale magnesium smelting factory, there is no doubt that using the steam jet vacuum pump, for an old factory also adopt mechanical vacuum unit in gradually transform using the steam jet vacuum pump. At present, the steam jet vacuum pumps used in magnesium industry, the main pump and the pre-pump are all five-stage steam jet vacuum pumps, and the installation types are high-position type (over 10 meters) and semi-high-position type (5 meters) with their own characteristics and shortcomings. The new high efficiency steam jet vacuum pump developed by our company is very low (can be installed on the ground) and has been well used in other industries. Combined with the usage of magnesium smelting industry, and the characteristics of the industry, I research institute and the design and manufacture the new patent products: low efficient tertiary steam jet vacuum pump (main pumping and drainage are level 3) instead of the current in the smelting magnesium industry category five steam jet vacuum pump (performance parameters of the pump and 5) same further achieve the goal of energy conservation and efficient.

2. Development and application of a new high efficiency pure low level three-stage steam jet vacuum pump

Steam jet vacuum pump application in various industries in our country has a history of more than 50 years, because of its unique advantages, especially the suction gas containing dust in high temperature and large amounts of water vapor, other) vacuum pump for steam jet vacuum pump because of its operation is stable and reliable, no moving parts, less maintenance, long service life, etc, used in metallurgy, freeze drying, heat power, petroleum, chemical industry, light industry, textile, pharmaceutical, sugar, salt, paper, oil, food and other industries and fields. The steam jet vacuum pump relies on saturated or superheated steam with certain pressure as the working medium. The negative pressure (vacuum) generated by laval nozzle and venturi tube is equipped with the number of combined steam ejectors according to the vacuum degree required by users. The lower the vacuum degree is, the more the injector level is. In general, the vacuum degree required for magnesium refining is 5 ~ 10Pa (working pressure). The traditional steam jet vacuum pump must have five levels to reach. In order to reduce the load and steam consumption of the rear stage pump, condenser shall be equipped between the first stage and the fourth stage, and between the fourth and the fifth stage to cool the working steam and the wet steam being pumped. The working steam of the fifth level is discharged directly into the atmosphere or into the cooling pool. The consumption of multistage steam jet vacuum pump is very large, some manufacturers in order to use steam jet pump, specially equipped with steam boiler or expand the tonnage of the original boiler, in order to cool a lot of working steam, there must be a lot of cooling water, in order to save water, it is necessary to build the cooling water circulation system of cold water tower. The traditional multistage steam ejection vacuum pump must be installed at a height of more than 11 meters, and for the single-storey low-frame workshop must also be installed with a high platform, which will increase the capital investment and installation costs. These are the three main elements of the steam jet vacuum pump and the three problems existing in the steam jet pump. Therefore, the research and development of multi-stage steam jet vacuum pump with low steam consumption, low cooling water consumption and low rack installation has been the subject of my research. After more than ten years of continuous improvement, innovation and development, a new type of high efficiency pure low level (ground mounted) multistage steam jet vacuum pump has been developed. The first stage can replace the traditional three-stage steam jet vacuum pump, the second stage can replace the traditional four-stage steam jet vacuum pump, and the third stage can replace the traditional five-stage steam jet vacuum pump. Compared with the traditional steam jet vacuum pump, the steam consumption can save more than 30 ~ 60%, and the cooling water outlet temperature is low, which is beneficial to the cooling water circulation system of the cooling water tower. Three stage steam jet vacuum pump designed and manufactured for vacuum magnesium industry, installed in low position (above ground). Simple installation saves time, labor and money, simple operation, no special management after the start, easy maintenance and other features.

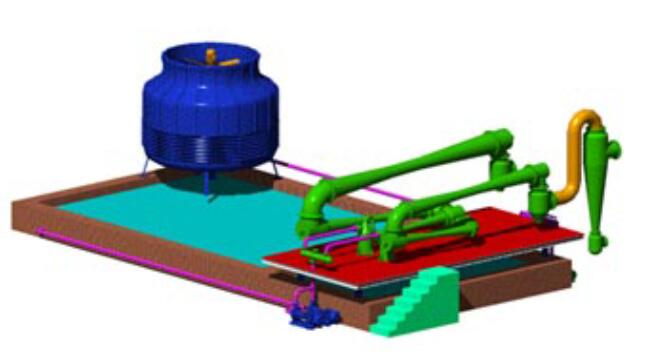

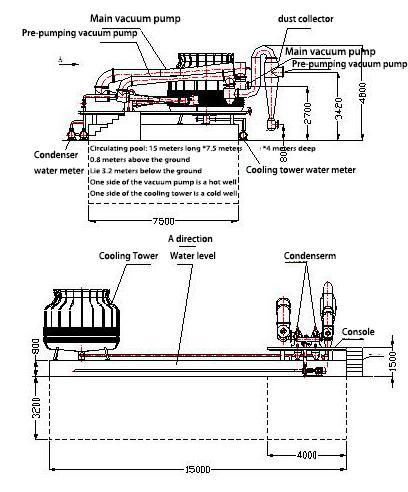

At present, it has been favored by magnesium industry. Please see the installation dimensions of the new high efficiency three-stage steam injection vacuum pump system (main pumping and pre-pumping).

3. Suggestions on the application of the new high efficiency low stage steam jet vacuum pump in magnesium industry

(1) Since the three-stage steam jet vacuum pump consumes less steam than the traditional five-stage steam jet vacuum pump, it can be combined with the characteristics of magnesium industry and the actual situation to form a reasonable supporting waste heat boiler to further achieve the purpose of energy saving, reduce operating costs, and achieve small and fine.

(2), try to use low temperature cooling water: the steam jet vacuum pump has a lot to do with how much consumption of steam and cooling water temperature, the most sensitive reaction, when the cooling water temperature of 25 oc or less developed by our company working steam consumption of steam jet vacuum pump can save to a third (by than traditional steam jet vacuum pump to save 2/3). Factories with conditions may use river water, underground water or primary water for steam jet vacuum pump cooling water, and then do other post water. In this way, we can save a lot of working steam consumption, reduce supporting equipment and operating costs, and achieve the goal of further energy conservation. At present, in the face of global warming and hot summer weather, the use of cold water tower to cool circulating water is not effective, and the only pursuit is to improve the cooling water temperature of steam jet pump. In this way, the steam consumption of steam jet pump will be greater, and the outlet temperature will be higher, which is more harmful to the cold water tower. It is a vicious cycle. It is also an important factor that steam jet vacuum pump can not work stably. Therefore, we can increase the amount of underground cold water and use groundwater as the cooling water of steam jet pump first, and then supply water for other posts. Many users of our products have adopted this scheme, saving the capacity of their boilers. Our products can be designed and manufactured according to the cooling water temperature required by different regions and enterprises.

(3), when the pump has a high temperature gas amounts of dust in order to decrease the dust cleaning and maintenance of the steam jet vacuum pump, near the steam jet pump in the drainage system, install a filter near the reduction furnace equipped with vacuum valve easy to operate, install a dust collector before vacuum valve, in order to quickly switch the main pumping and drainage (vacuum), frequently discharge dust, the dust is not or less into the vacuum pipeline, reduce the number of cleaning and maintenance, shortening the time of loading and discharging, is a beneficial measures. (See installation instructions for details)

(4) Our new products have been designed on a large scale. Please use our large-scale process to build a new factory or expand a new workshop, which will bring you the purpose of simplicity, speed and cost saving.

4. Conclusion

Our company research and development of the new high efficiency pure low level multistage steam jet vacuum pump, we are convinced that will soon be the favor of the majority of users and recognition, our company has a special scientific research institute, product innovation and improvement, so that all our products in the forefront of the advanced position and invincible.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)