Roots blower impeller wear reason

What causes the wear of Roots blower impeller?

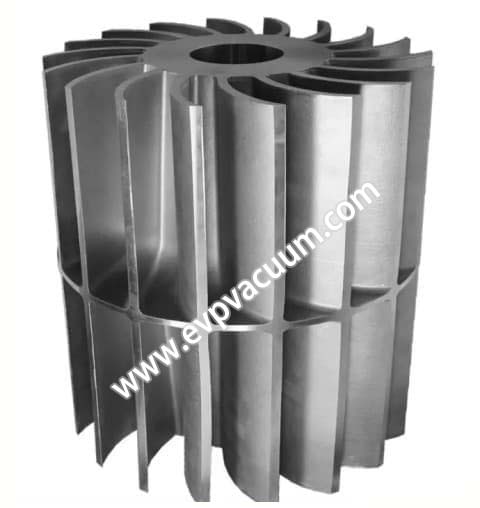

Some customers will find that the effect of Roots blower will slowly decline in the process of using it. What is the reason? If you buy roots blower, the wear of impeller can not be ignored in the use of Roots blower. The impeller of Roots blower is an important internal part. There are many factors causing wear, so the wear phenomenon is complex. So what causes the wear of Roots blower impeller? Follow the EVP vacuum pump manufacturer to learn about it.

1. Abrasive wear

The wear of uneven contact surface caused by filing effect under relative motion or abrasive action of dispersed solid particles between interfaces. It has the greatest influence on the wear degree of impeller. In Roots blower, the relative movement of solid particles with the surface of parts at a certain speed will cause abrasive wear.

2. Fatigue wear

It is caused by surface fatigue stress (or temperature or impact) resulting in surface crack or scale shedding.

3. Erosion and wear

Surface abrasion caused by erosion of metal surface by solid particles.

4. Adsorption wear

The results show that when other conditions are the same, even if the machining accuracy and cleanliness of the machined surfaces are improved to make them fit each other better, the wear does not decrease. On the contrary, because the interface is close, the molecular adsorption effect is obvious, which aggravates the interface wear, which is called adsorption wear.

5. Other faults

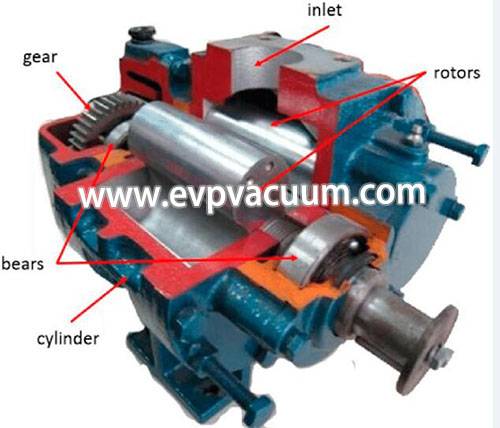

If roots blower has other faults, it may also cause impeller damage, such as bearing damage, gear damage and so on.

Generally speaking, the wear of Roots blower impeller in various situations is different, but it is basically local wear. The wear parts of the impeller are mainly located on the working face of the blade and near the rear disc. We should pay attention to maintenance in daily use.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)