Roots blowers supply

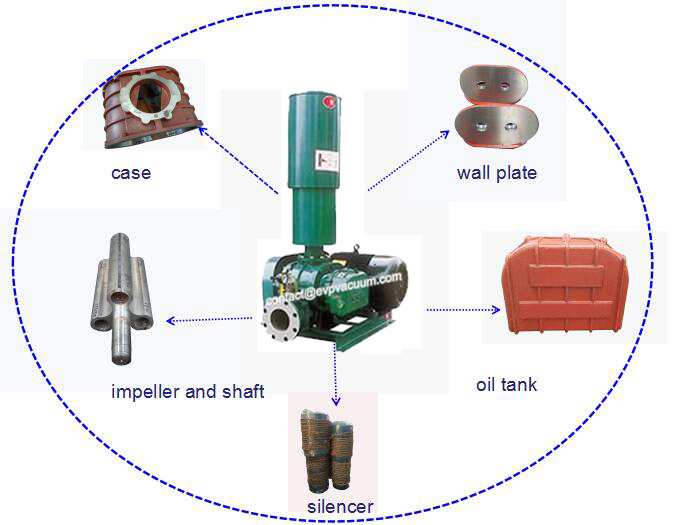

EVP company supplies three-leaf roots blower, which is a new product automatically developed on the basis of the advanced technical characteristics of various types of roots blower at home and abroad.

Roots blower and high pressure is to high temperature and high pressure of compressed gas export after cooling through an inlet port element of the import volume again, make its internal pressure with the exhaust pressure to achieve balance in advance, in order to reduce the gap after the opening of backflow impact strength, reduce exhaust airflow pulsation, thereby reducing noise and vibration of the fan, and reduce exhaust temperature.

Compared with the normal temperature use, the temperature field of the components is different greatly, which has a great influence on the clearance design of each part.

Product display

Flow range: 0.2m3/min-186m3/min

Pressure range: 9.8kpa-78.4kpa

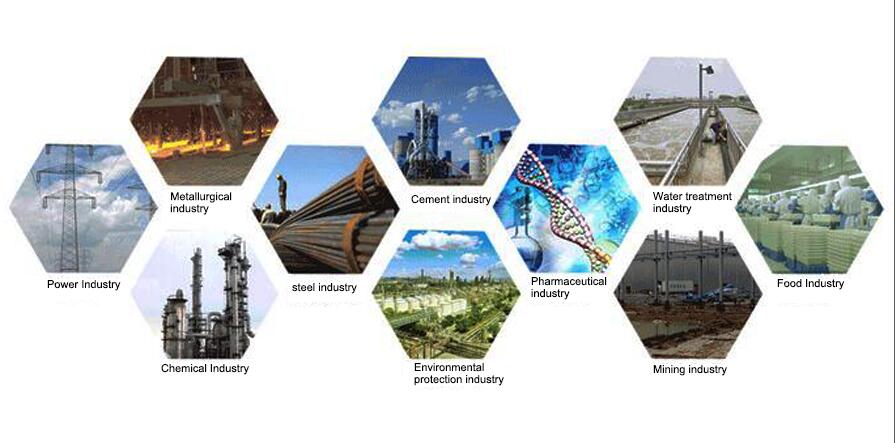

Application of three-leaf roots blower

Three-leaf roots fans are widely used in electric power, chemical industry, cement, steel smelting, pneumatic conveying, sewage treatment, and other departments and industries. The conveying medium is clean air.

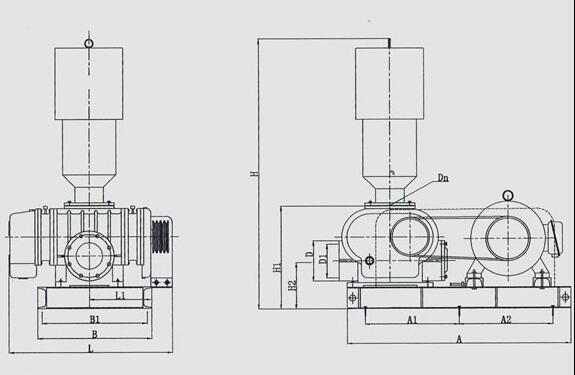

Belt drive mounting dimensions

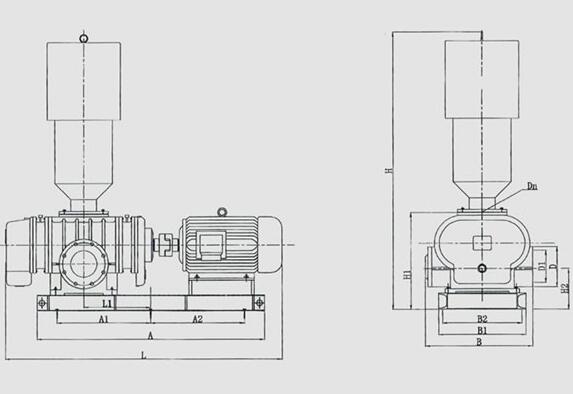

Mounting dimensions of direct drive

High temperature roots fan design requirements:

1. Design of thermal insulation structure and selection of thermal insulation materials

In order to reduce the influence of high temperature gas on the lubrication drive of blower, heat insulation measures should be considered in the structural design. A side plate is added to the baffle plate at both ends of the fan, and a heat insulating layer — a heat insulating gasket with low thermal conductivity — is added between the side plate and the baffle plate to effectively reduce the heat transfer from the machine chamber to both ends. At the same time, heat insulation spacers are also used between the wall panel and the partition to reduce the heat transfer from the partition to the wall panel. This kind of heat insulation structure and the heat insulation material choice, is advantageous in reducing the gas heat transfer to the mechanical transmission part.

2. Sealing of high-temperature gas

High-temperature gas seal using double-end mechanical seal, not only good sealing, in line with the requirements of the sealing performance of the medium, and the circulating flow of machine sealing liquid can take away part of the heat conduction through the diaphragm and its own heat, so that the fan bearings, gears and other transmission parts need low temperature operation in a good working state. For sealing materials, in addition to considering the suitability of medium, but also consider the adaptability of high temperature. The sealing machine adopts the metal material of corrosion resistance and high temperature resistance and the o-ring of perfluoroether material.

3. Auxiliary cooling measures

Although again good adiabatic material also cannot achieve adiabatic effect, heat transfer is inevitable, below the influence of high temperature, partial heat can pass air cavity and rotor continuously to machine seal, wallboard, bearing, oil tank and gear transfer. In order to ensure the reliable operation of the fan, the wall panels on both sides of the blower are changed from the conventional closed structure to open structure, which further reduces the wall panel temperature and axial temperature by relying on air convection. The main and auxiliary oil tanks adopt reinforced water-cooled jacket structure to fully heat exchange to reduce the temperature of lubricating oil.

4. Selection of high-temperature materials and high-temperature resistant parts

The main components of high temperature gas overflow are made of high performance ductile iron, o-ring seal is made of perfluoroether, and the surface coating of parts is made of high temperature resistant paint. Other components such as oil seals, bearings and lubricants are selected with temperature adaptability in mind.

5. Parts matching and impeller clearance

The fitting size of blower parts should consider the influence of temperature. The fan housing clearance, impeller clearance, wall panel clearance and gear clearance are important design points in the design and manufacture of roots blower. Compared with the normal temperature use, the temperature field of components differs greatly, which has a great influence on the design of each part clearance.