roots vacuum pump and roots blower difference between

Vacuum pump equipment has been widely used in electric power, sewage treatment, environmental protection, chemical industry, steel, building materials, pesticides, pharmaceuticals and other industries.

In recent years, the demand of Roots vacuum pump (negative pressure roots blower) is particularly high in some countries and regions, so it is of strategic significance to seize these markets. Moreover, roots vacuum pump has been tested in petroleum, chemical, plastic, pesticide, steam turbine rotor dynamic balance, aerospace space simulation and other devices for a long time, so it should be vigorously promoted and applied in China. It is also widely used in petroleum, chemical, metallurgy, textile and other industries.

Since roots vacuum pump is widely used, the following EVP vacuum pump manufacturers will introduce the following concepts and precautions in use:

1、 Concept of Roots vacuum pump and its difference with roots blower

Roots vacuum pump is a kind of rotary positive displacement vacuum pump. Its structure is evolved from roots blower. It is mostly used in Roots vacuum unit to improve pumping speed and vacuum degree of front stage pump. In fact, the structure and principle of Roots vacuum pump and roots blower are the same. Roots blower is used for positive pressure condition, while roots vacuum pump is used for negative pressure condition. In structure, the two main machines are the same, but there are slight differences in inlet and outlet. Roots blower is generally connected with its exhaust outlet, while roots vacuum pump is connected with its suction inlet The Conduit.

2、Roots vacuum pump working principle :

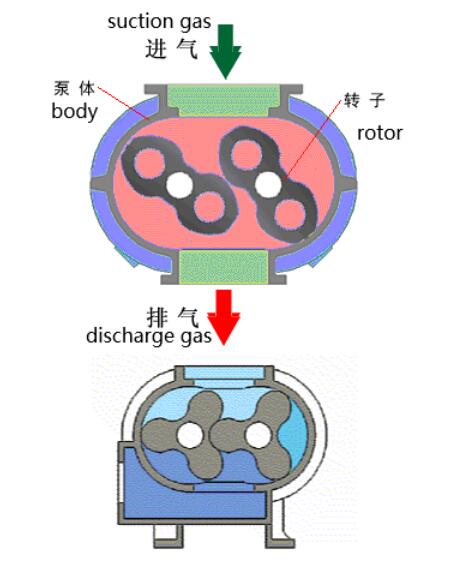

Roots vacuum pump is a kind of vacuum pump without internal compression, usually the compression ratio is very low, so the high and medium vacuum pump needs the front stage pump. It is a vacuum pump that moves the gas by pushing a pair of blade shaped rotors in the pump cavity synchronously and reversely.

Roots vacuum pump is a kind of mechanical vacuum pump with a pair of synchronous and high-speed rotating sole rotors. The pump can not be pumped separately, and the front stage needs oil seal and water ring to discharge air directly.

Its structure and working principle are similar to roots blower. When it works, its suction port is connected with the vacuum container or main pump of vacuum system. There is no contact between the rotor and the rotor, or between the rotor and the pump shell of the vacuum pump, and the clearance is generally 0.1-0.8 mm; oil lubrication is not required. The rotor profile includes arc, involute and cycloid. Involute rotor pump has high volume utilization rate and easy to ensure machining accuracy, so involute type is used for rotor profile. The rotary speed of Roots vacuum pump can be as high as 3450 ~ 4100 rpm; the pumping rate is 30 ~ 10000 L / S (1 L = 10-3 m3); the limit vacuum is 6.5 × 102 PA for single stage and 1 × 103 PA for double stage.

Roots blower schematic diagram

The limit vacuum of roots pump depends not only on the structure and manufacturing accuracy of the pump itself, but also on the limit vacuum of the previous stage pump. In order to improve the limit vacuum degree of the pump, roots pump can be used in series. The working principle of roots pump is similar to roots blower. Due to the continuous rotation of the rotor, the extracted gas is drawn into the space V0 between the rotor and the pump shell from the air inlet, and then discharged through the exhaust port. Because the V0 space is completely closed after suction, there is no compression and expansion in the pump chamber. However, when the top of the rotor turns around the edge of the exhaust port and the V0 space is connected with the exhaust side, a part of the gas will recoil into the space V0 due to the high gas pressure on the exhaust side, which makes the gas pressure suddenly increase. When the rotor continues to rotate, the gas is discharged from the pump. In the pump cavity of roots pump, there are two “8” shaped rotors installed vertically on a pair of parallel shafts, and a pair of gear belts with transmission ratio of 1 act in the opposite synchronous rotation motion. There is a certain gap between the rotors and the inner wall of the pump shell, which can realize high speed operation.

The basic structure and principle of Roots blower and roots vacuum pump are similar, but roots vacuum pump and roots blower are different. Roots vacuum pump is used for suction and is often used for negative pressure environment, while Roots fan is used for blowing air, which is usually used for positive pressure environment. Therefore, for roots equipment, their inlet and outlet are opposite. One pressure gauge is positive pressure gauge, the other is negative pressure pressure gauge, That is to say, they are essentially the same, but the price of Roots vacuum pump is slightly higher than that of Roots blower!

3、 Roots vacuum pump Characteristics :

Roots vacuum pump has the advantages of fast start-up, low power consumption, low operation and maintenance costs, high pumping speed and high efficiency. It is not sensitive to a small amount of water vapor and dust in the extracted gas. It has a large pumping rate in the pressure range of 100-1 PA, which can quickly remove the gas suddenly released. This pressure range is just between oil sealed mechanical vacuum pump and diffusion pump. Therefore, it is often connected in series between the diffusion pump and the oil sealed mechanical vacuum pump, which is used to increase the pumping volume in the middle pressure range. At this time, it is also known as the mechanical booster pump.

Roots vacuum pump is widely used in smelting, degassing, rolling in vacuum metallurgy, vacuum distillation, vacuum concentration and vacuum drying in chemical, food and pharmaceutical industries. Vacuum pump accessories for vacuum pump noise control, vacuum pump muffler.

4、 Precautions when using roots vacuum pump:

1. Roots vacuum pump must be equipped with the front stage pump, not used alone.

2. Roots vacuum pump is mostly used in Roots vacuum unit, its function is to improve pumping speed and vacuum degree of the front stage pump.

3. If the vacuum degree of Roots vacuum pump is reduced during use, it is necessary to check whether the clearance between the rotors of Roots vacuum pump has changed. If the rotor clearance of Roots vacuum pump becomes larger, it is necessary to replace roots vacuum pump.

4. When choosing roots vacuum pump, attention should be paid to the sealing mode of vulnerable parts of Roots vacuum pump. Generally, roots vacuum pump adopts mechanical seal, which can effectively improve the working efficiency of Roots vacuum pump.

5、 The obvious difference between Roots blower and roots vacuum pump is that roots blower is used for positive pressure air supply, while roots vacuum pump is used for negative pressure suction.

According to the different structure and vacuum degree, roots vacuum pump can be divided into ordinary roots vacuum pump with medium and high vacuum degree and rough vacuum roots vacuum pump with direct exhaust. The former needs to be used together with the front stage pump to ensure that the pressure difference is within 2kpa-10kpa. If the pressure difference is too large, the compression ratio will increase, the power will increase and the thermal expansion will cause the motor overload or the rotor thermal expansion locking; the latter can make the equipment adapt to the pressure difference of up to 88kpa by increasing the structural clearance and equipping with air cooling or water cooling at the same time, In other words, the so-called direct exhaust atmosphere, due to the large gap, the vacuum degree is far less than the former.

Therefore, roots blower can be used instead of Roots vacuum pump in some temporary low vacuum environment (roots vacuum pump is connected to the system by inlet, and the system is pumped by the inlet; roots blower is connected with the system, and the exhaust port is used to supply air to the system). However, it is only limited to the rough vacuum environment, and can not be applied to vacuum or other occasions with high requirements.

However, on the contrary, no one is willing to replace roots blower with roots vacuum pump in practical application. On the one hand, the price of Roots vacuum pump is much higher than that of Roots blower due to the large difference in cost performance; on the other hand, ordinary roots vacuum pump, as mentioned above, needs to be used together with the previous stage pump, which can not be started under normal pressure, so it is impossible to use it.