Roots Vacuum Pump Manufacturer Sales

EVP Roots Vacuum Pump Manufacturer, High Efficiency and Energy Saving. Roots vacuum pump is strictly manufactured, mechanical booster pump, low noise vacuum pump, high speed front pump, manufacturer sales, high-end mechanical Roots pump, three-leaf Roots vacuum pump, old enterprises, casting good products.

Because the transmission structure adopts flexible hydraulic device, Roots vacuum pump has the following advantages:

1. Under the condition that bypass pipes and valves are reduced or frequency converters are omitted, the overall pumping speed effect far exceeds that of traditional booster pumps.

2. Compared with the traditional direct drive, the pump is not easily damaged even when the inlet pressure suddenly changes or foreign body is inhaled.

3. Roots vacuum pump can be started at the same time with the front pump at atmospheric pressure, which acts on the whole pumping process earlier, thus significantly shortening the pumping time.

Product parameters:

| Model | ZJ-150 | ZJ-300 | ZJ-600 | ZJ-1200 | |

| Pumping speed(L/s) | 150 | 300 | 600 | 1200 | |

| Ultimate pressure (Pa) |

1stage piston pump as backing pump | 5×10-2 | |||

| 2 stage piston pump as backing pump | 1×10-1 | ||||

| Max. allowable diff. pressure(Pa) | 8×103 | 5×103 | |||

| Motor rotary speed(RPM) | 3000 | ||||

| Suitable motor power(kW) | 2.2 | 4 | 7.5 | 11 | |

| Flange size | Inlet(mm) | 100 | 150 | 200 | 250 |

| outlet(mm) | 100 | 150 | 200 | 200 | |

| Cooling water consumption(L/h) | 120 | 150 | |||

| Allowable temperature(℃) | 100 | ||||

| Vacuum pump oil | 100# | ||||

| Weight(without motor)(kg) | 195 | 250 | 760 | 860 | |

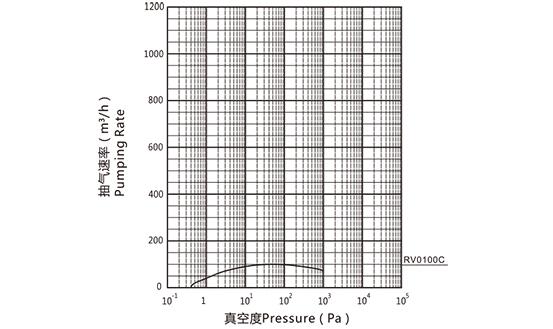

Product Curve

Roots vacuum pump Installation instructions :

(1) Installation site:

1. Roots vacuum pump should be installed in bright and dusty buildings.

2. The installation environment temperature of Roots vacuum pump is 5-40 C.

3. There should be enough room around Roots vacuum pump to facilitate routine inspection, maintenance, disassembly and assembly.

(2) Foundation works:

1. Small and medium-sized pumps can be installed on the same rack as front-stage pumps to form a unit and then installed on the concrete foundation. Large pumps must be installed separately to pour concrete foundation.

2. Determine the area and depth of concrete foundation according to the weight of Roots vacuum pump and the pressure resistance of foundation.

3. In order to bury foundation bolts in concrete, sufficient voids must be left in the grouting of concrete foundation according to the location of the base hole.

4. Level the base surface.

(3) Installation:

1. Make a wooden frame according to the position of the base hole, fix the foundation bolt on the wooden frame, put it into the reserved hole, then pour concrete into the reserved hole, place the number, and remove the wooden frame after concrete hardening.

2. Put the Roots vacuum pump on the foundation, calibrate the level with the level gauge, harden the uneven part with the metal gasket, tighten the foundation bolt, and fill the bottom gap with cement.

(4) Pipeline installation:

1. There are no foreign bodies such as welding slag and impurities in the intake and outlet gas pipelines, which have sufficient channel capacity.

2. An elastic pipe should be installed in the connecting pipe between the outlet of Roots vacuum pump and the inlet of the front stage pump to reduce the influence of the vibration of the front stage pump.

3. In order to shorten the pre-pumping time in general systems, besides connecting the inlet of the front pump with the outlet of Roots vacuum pump, by-pass pre-pumping pipeline and valves are also needed. Roots vacuum pump with relief valve can work under high inlet pressure, so it can not install pre-pumping pipes and valves.

4. In order to prevent the return of oil or water when the front-stage pump stops, the inlet pipeline of the front-stage pump should be equipped with an exhaust valve or a check valve.

5. Pipeline connecting flange must be sealed with 0-shaped rubber sealing ring and coated with vacuum coke grease. The whole vacuum system must be sealed without leakage.

6. The cooling water inlet and outlet of the pump should be connected with the pipeline, and a valve should be installed on the inlet pipe to adjust the water volume.

(5) Electrical installation:

1. Because Roots vacuum pump can only work within the prescribed inlet pressure range, and when the current stage pump stops working, Roots vacuum pump must stop working at the same time. Therefore, electrical equipment must have interlocking and necessary automatic protection.

2. The wiring of the motor should make the steering of the pump conform to the direction indicated by the arrow.

3. Small pumps can start directly, and large pumps must be equipped with starters.

Roots Vacuum Pump Manufacturer Products Pictures:

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)