Rosin deep processing — application of esterification reaction vacuum pump

Rosin deep processing — application of esterification reaction

Resin acids can react with a variety of alcohols to produce corresponding esters, such as methyl esters, glycerides, etc. Due to the higher steric hindrance of the carboxylic group of the resin, this reaction requires higher temperature and more intense conditions than the esterification of fatty acids.This hindrance determines that the bond of rosin esters is difficult to be broken by water, acid or base.Modified rosin, such as hydrogenated rosin, polymerized rosin, disproportionated rosin, Malay rosin, etc. all have carboxyl groups, which can also generate corresponding ester products.

1.Ethyl rosin

Direct synthesis route: Rosin and ethanol are directly catalyzed in the presence of H2SO4 to obtain rosin ethyl ester. The crushed rosin and ethanol are heated and melted in the amount of 1:4 (moL ratio), and 98% H2SO4 with 8-15% of the rosin is added as a catalyst. The temperature is maintained at 80-90°C to produce normal ethanol reflux, and the ester is maintained. After 72 hours of chemical reaction, crude ethyl resinate is produced, and the esterification rate reaches 60-65%. After the esterification is completed, the ethanol is recovered, and the crude ester is washed with water to PH6-7 for dehydration. The dehydrated crude ester is subjected to vacuum distillation at a pressure P less than 20mmHg, and the gas phase temperature is 160 ℃ before the distillate, and the liquid phase temperature is 280- 310℃, pressure 5-20mmHg is the finished product distillate.

2.Rosin glycol ester

Rosin and cholesterol use zinc powder or boric acid as a catalyst to react at 250-260 to prepare rosin glyceride.

2C19H29COOH +(CH2OH)2 Zn粉 → (C19H29COOCH2)2 + 2H2O

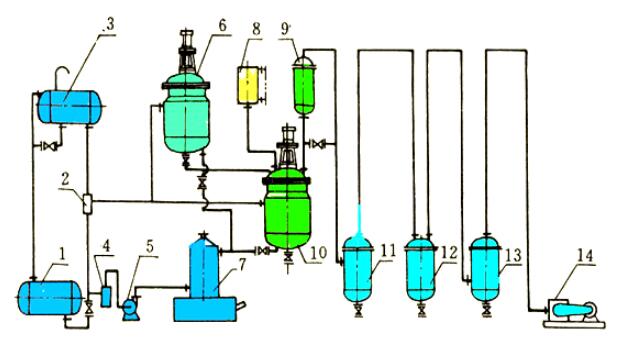

3.Attention to the selection of vacuum pump in rosin esterification process:

The main role of the vacuum pump is to remove the water generated by the reaction, so that the reaction to the right normally; As well as the rectification of crude ester, how to determine the gas volume and vacuum degree of vacuum pump is very important in the process, of course, the form of vacuum pump is also very important, dry oil-free vacuum pump is a trend of choice, please consult professional selection engineer for details.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)