rotary vane vacuum mechincal pump

Rotary vane vacuum mechanical pump overview

Rotary vane vacuum mechanical pump is a new and advanced imported product, which is a blank in China. It has eccentric device, the rotor inside the pump hole and rotor groove inside the rotor piece, when the rotor drives the rotor piece to rotate, the rotor piece tightly adheres to the cavity wall to separate the inlet and outlet, and makes the volume of the air product cavity periodically expand and inhale, and the volume of the exhaust cavity periodically reduce the gas, push the exhaust, so as to obtain a vacuum. Compared with similar domestic products, this pump has the advantages of low power consumption, high vacuum degree, low noise, beautiful appearance and light weight, etc.2X series vacuum pumps are basically the same in shape and structure, and the pump is driven to the rotor by the motor through the triangle belt. The motor and pump are fixed on the chassis with screw plates.

Rotary vane vacuum mechanical pump structure

The rotary vane vacuum mechanical pump is a kind of positive displacement pump, which draws in and compresses the gas by the help of the rotary vane in the pump chamber continuously, and finally expels by the exhaust port. Pump is mainly composed of stator, rotor, rotor, etc., the rotor is eccentrically loaded into the stator cavity. There are two rotor blades in the rotor groove, and the rotor spring is placed between the two rotor blades. The inlet and exhaust vents of the stator are separated into two parts by the rotor and rotor blade.

When the rotor stator rotating cavity when, rotary vane in the spring tension of common port under the action of centrifugal force in itself and close to the pump cavity wall slip, periodically will air inlet side of the cavity expands and suction gas content, narrow outlet volume at the same time, will have the suction gas compression, and then discharge from the vent so as to achieve the aim of extraction.

Rotary vane vacuum mechanical pump operating range

2X rotary vane vacuum pump is a two-stage structure, its working performance is composed of two parts: high pressure stage and low pressure stage, its suction inlet is connected with the vacuum container or vacuum equipment, and a large amount of gas in the container will be inhaled and discharged during operation. When the equipment is vacuumed, the high-pressure stage exhaust valve plate will be closed, and the gas inhaled in the high-pressure stage will be transferred to the second stage, which will be inhaled and discharged, so that the vacuum equipment can obtain a certain amount of vacuum. The technical parameters of the pump are 6 10-2pa. According to the user situation, can be equipped with vacuum booster pump, the pump as the front pump, because of the booster pump pumping force is strengthened, front pump continuous pumping, can make your equipment get higher vacuum.

What is the function of rotary vane vacuum mechanical pump

Rotary vane vacuum pump can be widely used in air conditioner, refrigerator, fluorescent lamp, inside the production and electronics, metallurgy, medicine, chemical, filter oil machine, printing machines, packaging machines and other industrial, can also be used alone, as the other high vacuum pumps, diffusion pumps, roots pump and molecular pump, a former stage pump, mainly used for electronic instruments, medical equipment and other supporting application and experimental research.

Rotary vane vacuum mechanical pump application

As the front pump of high vacuum pump

Vacuum (freeze) drying

Vacuum filtration

Vacuum distillation

Vacuum inspection

Vacuum coating

With other instruments and equipment

Rotary vane vacuum mechanical pump product display

Product specifications

| 2X-4A | 2X-8A | 2X-15A | 2X-30A | 2X-70A | 2X-100A | |||

| Pumping speed(L/s) | 4 | 8 | 15 | 30 | 70 | 100 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ²(5×10-4Torr) | ||||||

| Total pressure | 2.66(2×10-2 Torr) | |||||||

| Rotary speed(r/min) | 450 | 320 | 320 | 450 | 420 | 360 | ||

| Motor power(Kw) | 0.55 | 1.1 | 2.2 | 3 | 5.5 | 7.5 | ||

| Working voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Cooling Mode | Natural cooling | Water cooling | ||||||

| InletDiam(mm) | I.D. | 25 | 40 | 50 | 65 | 80 | 80 | |

| O.D. | 30 | 50 | 80 | 85 | 100 | 125 | ||

| Dimensions(mm) | Length | 540 | 790 | 790 | 810 | 910 | 1130 | |

| Width | 335 | 430 | 530 | 480 | 650 | 740 | ||

| Height | 380 | 540 | 540 | 560 | 700 | 690 | ||

| Oil capacity(L) | 1.0 | 2.0 | 2.8 | 3.0 | 4.2 | 5 | ||

| Recommend solenoid valve | DDC-JQ25 | DDC-JQ40 | DDC-JQ40 | DDC-JQ65 | DDC-JQ80 | |||

| Noise (dB A) | 65 | 70 | 70 | 70 | 75 | 90 | ||

| Weight(kg) | 60 | 158 | 202 | 230 | 480 | 560 | ||

How to install the rotary vane vacuum mechanical pump

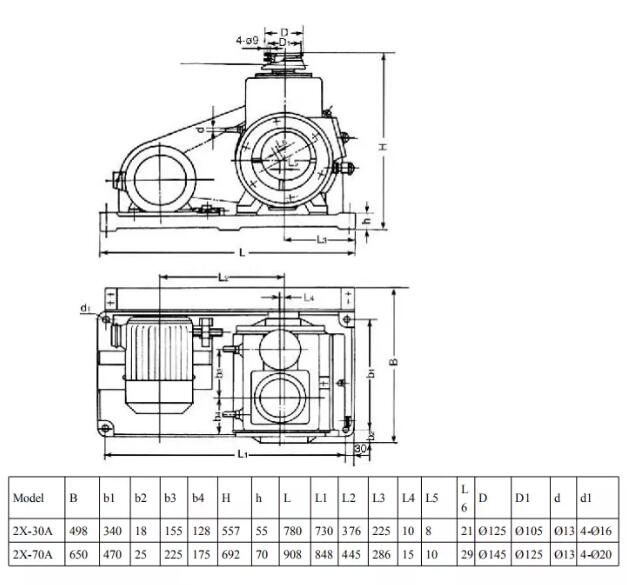

Installation dimensions

Rational installation of rotary vane vacuum pump can not only ensure the normal operation of the pump, but also extend the service life of the pump. Then how to install the rotary vane vacuum pump is correct, then the EVP vacuum pump expert will introduce the rotary vane vacuum pump installation method.

Firstly, carefully remove the rotary vane vacuum pump body, prepare accessories and instruction manual after unpacking and keep well for future use. Remove the filler, wipe the surface of the pump dust, dirt. Count according to packing list.

Secondly, rotary vane vacuum pump installed in the clean environment, good ventilation, adequate light in line with the requirements of article 4 indoor. According to the use of the pump should be installed in a certain amount of space to facilitate the maintenance of the operation. See pump dimensions. Rotary vane vacuum pump can be placed on a solid flat ground, do not need special foundation, if you need to fix can be added with screws and foundation firm, foot screw size see. Rotary vane vacuum pump such as close to the use of precision instruments, should be considered to increase the shock device.

Connect the vacuum hose or flange to the rotary vane vacuum pump. If the flange is connected, there should be rubber groove on the flange. See figure 50 for the form and size. The amount of gas in the pumped container should be consistent with the pumping speed of the pump. The pumping speed relation of the rotary vane vacuum pump is shown in figure 4. It is recommended to install a vacuum valve between the pump and the vessel to control the gas flow. For the pump and it is recommended to install a vent valve (or solenoid valve) in order to stop the pump to vent, can prevent oil return and easy to start.

Then, according to the motor sign voltage and wiring mode connected to the power supply, and it is recommended to use safety device to avoid overload, determine the motor rotation direction, should be consistent with the direction of the arrow on the pump. Remove vent plug and attach vent hood or remove cover from vent vent. Rotary vane vacuum pump needs to be connected to water source.

Finally, if it is necessary for the pump to remove poisonous and corrosive black metal gas, gas with chemical changes to the vacuum oil, and gas exceeding the room temperature and dust, it should be equipped with neutralization, cooling, filtering and other related devices in the intake pipe for use, otherwise it will affect the performance and service life of the rotary vane vacuum pump. When the harmful gas is removed, a corresponding pipe should be installed to lead the discharged gas away from the outdoor work area for treatment.

Note: care should be taken during installation to prevent iron filings, dirt and dust from falling into the pump