Rotary vane vacuum pump buying guide

The manufacturer of EVP vacuum pump has produced top-level vacuum pump equipment. We have introduced in depth the purchase guide of vacuum pump on the website. True pump equipment used in each industry is different, the following specific for you to introduce the purchase of rotary vane vacuum pumps need to consider factors.

There are many different types of rotary vane vacuum pumps in the market. Choosing the right rotary vane vacuum pump for your application may be a challenge. A variety of factors need to be considered when selecting the appropriate model, including final vacuum depth, free air displacement (flow rate), wet or dry operation (oil or oil free) and chemical resistance. These are the basic starting points for making a wise decision to buy the right product for you.

At present, there are various types of vacuum pumps on the market, including liquid ring vacuum pump, rotary vane vacuum pump, Roots vacuum pump, molecular pump and so on. When choosing a vacuum pump, it is important to consider which chemicals you will use and the concentration. This will ensure that you do not choose the wrong product.

According to the application requirements, each type can be used in various applications; this is why it is very important to choose the right model and size for your application for equipment life and system operation. The first step in choosing a high quality vacuum pump is to determine the operating parameters of the required application.

When choosing the right pump, it is important to know the vacuum depth required for the application.

1. Low vacuum is mainly used to move liquids through filters and other basic glassware liquids.

2. Medium vacuum is used for solvent recovery and other applications. You can evaporate or repair solvents.

3. Medium to high vacuum can be used more widely, such as plant extracts. Importantly.

4. Reduce the boiling point of some compounds to make them gaseous.

5. High vacuum applications are most suitable for semiconductor industry, clean rooms, optical devices, etc. All of these require deeper vacuum.

Ultra-high vacuum (UHV) is more widely used in theoretical applications in the study of space and some nuclear reactions.

Choosing the right vacuum depth and flow rate will have a significant impact on your system. A small system does not need to have a large flow pump, because the system is very small, so it does not need such a large flow rate to clean the atmosphere. However, for larger systems, this is the opposite; the larger the system, the better the flow, otherwise you may need to wait longer to vacuum the system.

For example, if the user has a vacuum oven for removing low boiling point volatiles from the product, a high vacuum depth (sub-Torr) is required to completely remove some solvents in addition to heating. If the oven is small, a small direct drive pump can be used to quickly empty the system, while for larger ovens, a larger (higher free air displacement) pump can be used. The second step is to determine whether the pump will be exposed to corrosive compounds.

Corrosion resistance? Oil or no oil?

Corrosion-resistant pumps may be more suitable for longevity, depending on which items are degassed/purged in the oven. Dry or oil-free pumps may be required here. Understanding the driving forces behind specific applications is the key to selecting pumps. For example, desktop fractionation. In desktop scale fractionation, vacuum is the environmental operating parameter, while heat is the driving force.

Vacuum reduces the boiling point of compounds, while heating/stirring evaporates them into vapors, which then turn them into condensates. Free air emissions (measured under atmospheric conditions) are related to the air velocity through a given pump, which describes the speed at which a given vacuum pump reaches its limit vacuum.

For this reason, high-flow pumps are not necessary for this operation. Once the system reaches a high vacuum, the pumping speed will decrease dramatically (because the molecules of the pump are getting smaller and smaller). In addition, using too high distillation flow rate may cause molecules to condense in undesirable areas, because the pump pulls steam through where they are to collect.

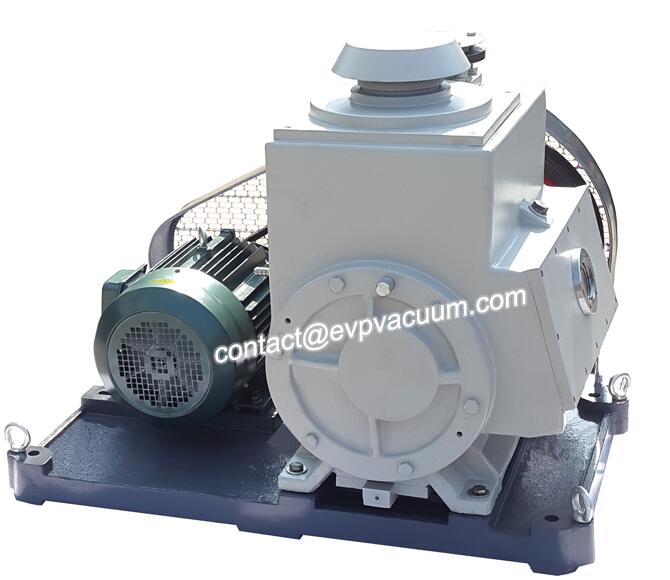

SV Rotary Vane Vacuum Pump:Vacuum Packaging &Vacuum Pasting,Vacuum Drying, Vacuum degassing, Vacuum impregnating,Lifting, transporting, suctioning, loading and unloading other industries.

2XZ Direct Drive Rotary Vane Vacuum Pump:It not only can be used alone, but also can be a backing pump of booster pump, diffusion pump, turbo molecular pump and titanium pump. It can be used for electric vacuum device manufacturing, thermos manufacturing, vacuum welding, printing, plastic, refrigeration equipment repair and instrument repair facilities, etc.

2X-A Rotary Vane Vacuum Pump:used for metallurgy, chemical industry, light industry, petroleum, medical, pharmaceutical, printing and dyeing, electronics, electric vacuum, semiconductor, food, atomic energy, textile, oil filter, printing machinery, packaging machines and other industries. In addition, in the vacuum smelting, vacuum brazing, vacuum impregnation, vacuum coating, vacuum heat treatment, vacuum drying, vacuum packaging process also uses 2X series rotary vane vacuum pump.

After determining the parameters, the next step is to determine the pump suitable for the required application and select the best options for budget, brand, integrity and/or availability. Many pumps may be suitable for specific operations, which is an important reason to understand the differences between types.

These are high-performance, usually low-cost; however, they use oils that must be replaced and expensive. The life expectancy of rotary vane vacuum pump depends largely on maintenance. Rotary vane vacuum pump uses oil to achieve tight sealing and lubricates parts to eliminate the heat of the rotor. It is recommended that these types of pumps be maintained every 3000 hours. These pumps can reach the depth limit vacuum level and have variable displacement capacity from low to high. These pumps are suitable for samples containing solvents, steam or high boiling point.

Although most vacuum pumps use one or more of these technologies, they are still vulnerable to corrosive chemicals and can hardly protect pumps from damage. To prevent these disadvantages, cold traps or vacuum traps should always be used to capture the steam escaping from the reaction vessel. These traps fit between the system and the pump.

Steam flows from the system to the pump through the trap, where the steam will condense due to the surface area/cold surface of the trap. Condensing steam from the outside of the pump will increase the life of the pump, reduce the amount of oil exchanged on the pump, and prevent undesirable situations. It is strongly recommended that traps be used when handling any type of steam to prevent pump damage or vapor concentration in the pump/pump oil. In addition, when polluted by condensate vapor, the oil in the oil pump will change the viscosity, thus reducing the pumping performance.

All these factors should be taken into account when choosing a suitable rotary vane vacuum pump for the industry. Therefore, you should be careful in choosing the style and capacity that suits you.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)