Rotary vane vacuum pump for food industry

Rotary vane vacuum pump product is not unfamiliar to everyone, but for the real understanding of the vacuum pump is in a small number, there are many functions of vacuum pump, for fruit and vegetable fresh-keeping and cooked food processing, vacuum pump in this area is also quite widely used, this paper mainly describes the rotary vane vacuum pump in cooked food processing and fruit and vegetable processing. The use of freshness.

The ideal cooling method that meets the following requirements is vacuum cooling.

1, fruits and vegetables harvested after harvest are still living individuals. Essential substances and energy are obtained through respiration. Breathing, on the one hand, maintains the life of individuals, but on the other hand consumes stored substances. As a result, fruits and vegetables began to age. The purpose of preservation is to delay aging, so it is necessary to control breathing, and the most closely related factor to breathing is temperature. Respiration releases both energy and temperature. In turn, it promotes respiration and accelerates the senescence of fruits and vegetables. Obviously, if we can reduce the temperature of fruit and vegetable and environmental temperature, we can effectively control breathing and then delay aging. Therefore, the pre-cooling treatment must be carried out after fruit and vegetable harvesting to remove the field heat as soon as possible and reduce the respiratory heat. It creates conditions for prolonging freshness. Nowadays, natural cooling mode is generally used for cooling, which covers a large area and takes a long time. It is not only difficult to meet the requirements of rapid pre-cooling, but also unsuitable for industrial production. There are also direct cooling into the cold storage, which is unreasonable and inexpensive, and can not achieve rapid and uniform cooling.

2. Cooked food must be cooled before packaging. The traditional cooling methods include natural cooling, forced ventilation cooling, air conditioning cooling and cold storage cooling. These cooling methods not only have a long cooling time (several to more than ten hours), slow turnover and occupy more land, but also have uneven cooling, large temperature difference between surface and center, and more importantly, affect food hygiene and safety. During the cooling process, the bacteria in the air will inevitably stick to the food and cause the “secondary pollution” of the food, especially between 50 and 25 degrees Celsius, which is the high-speed breeding area of bacteria. Rapid passage through this temperature range can greatly reduce the generation of bacteria, easily control the original bacterial quantity, and thus help to improve food quality. Product safety and extend shelf life. This is of great significance for the implementation of the “Food Safety Law”. It can be seen that the sample used in food processing industry also needs an advanced method and equipment for rapid cooling.

Various vacuum acquisition techniques and corresponding vacuum cooling equipment

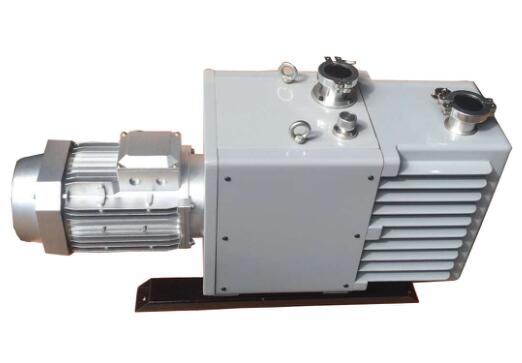

1, rotary vane vacuum pump, water trap combination system and fruit and vegetable vacuum pre Cooler:

Rotary vane vacuum pump is one of the most basic vacuum equipment in vacuum technology. This is an oil-sealed mechanical vacuum pump with large pumping speed, small volume, high limit vacuum and low working noise. In this vacuum pump, oil plays an important role. It has three functions of sealing, lubrication and cooling.

The principle of vacuum cooling is to cool itself by absorbing moisture when vaporizing water. Therefore, water vapor will be produced in the cooling process. If water vapor enters the rotary vane pump directly, it will cause the emulsification of the pump oil, which will not only affect the performance of the pump but also cause damage to the pump body itself. The solution is to add a water catcher in front of the pump to condense the water vapor into water at low temperature and drain it. For this reason, the refrigeration system must be reconfigured, and the water vapor is removed and then discharged by vacuum pump.

Vacuum precooler for fruits and vegetables is generally designed and manufactured according to the above principles. Its basic components are vacuum box, water catcher, refrigeration unit and rotary vane vacuum pump.

2. Water jet vacuum technology and normal temperature vacuum refrigerator.

Cooling of cooked food is different from pre-cooling of fruits and vegetables. The initial temperature is very high. Generally, over 90 C, a large amount of water vapor will escape during the cooling process. Therefore, if the combined system of rotary vane vacuum pump and water catcher is adopted, the water catcher and refrigeration unit must be matched very large, not only the unit is huge, but also the energy consumption is very high. Economics. If the water jet vacuum technology is applied to cooked foods, the cooling effect is very good.

The technology integrates three functions of vacuum, condensation and drainage. It uses a certain pressure of water flow, through symmetrically distributed nozzles with a certain lateral inclination, high-speed ejection, convergence in a focus, thus forming a negative pressure around, so that the vacuum box connected with it produces vacuum. In addition, due to the direct contact between water vapor and jet water, heat exchange, most of the steam condenses into water, which is removed through diffuser tube, and the volume is greatly reduced, thus further forming a higher vacuum.

If you want to know more about our va cuum pump products, or if you want to consult the vacuum pump please leave a message or send us an email at contact@evpvacuum.com

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)