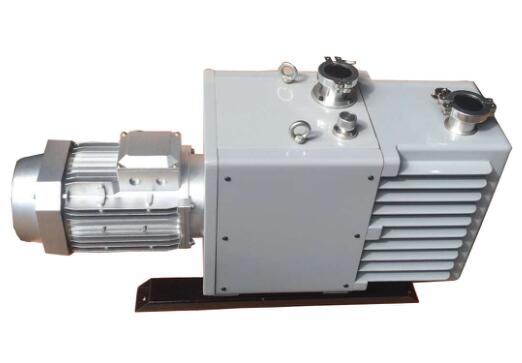

Rotary vane vacuum pump for medical industry

Rotary vane vacuum pump application

Rotary vane vacuum pump is a two-stage structure. Its working performance consists of two parts: high-pressure stage and low-pressure stage. Its suction port is connected with vacuum vessel or vacuum equipment. During operation, the gas in the vessel will be inhaled and discharged in large quantities. When the equipment obtains vacuum, the high-pressure exhaust valve sheet will be closed, and the gas inhaled by the high-pressure stage will be transferred to the second stage, and then inhaled and discharged by the second stage, so that the vacuum equipment can obtain a certain vacuum. The technical parameter of the pump is 6 * 10-2Pa.

According to the user’s usage, it can be equipped with vacuum booster pump, which can be used as the front pump. Because the booster pump’s pumping force is strengthened, the front pump is continuously pumped out, which can make your equipment obtain higher vacuum. The pump is suitable for metallurgy, chemical industry, electric light source vacuum, vacuum coating, food packaging, medicine, plastic absorption, electronics, drying and other fields.

1. Rotary vane vacuum pump is one of the basic equipment for gas extraction. It can be used alone or connected with super-high vacuum pumps such as booster pump, diffusion pump and molecular pump. It is widely used in the manufacture of electronic devices,Air drying, filtration, impregnation, coating, welding, smelting and laboratory equipment.

2. Rotary vane vacuum pump is allowed to operate for a long time in the ambient temperature range of 5 ~40 ~C and the inlet pressure is less than 10 torches. When the relative temperature of the extracted gas is more than 90%, the ballast valve should be opened.

3. The air inlet of the rotary vane vacuum pump should not exceed 3 minutes.

4. Rotary vane vacuum pumps are not suitable for extracting gases that corrode metals, react chemically with pump oil, contain particulate dust, and contain excessive oxygen, explosive and toxic gases.

Rotary vane vacuum pump operation instructions

1. Check the oil level. Oil level should be in the center of the oil mark, too low oil level can not seal the exhaust valve, affecting the vacuum; too high oil level can cause fuel injection when starting. Before running, remove the triangle belt and turn the motor to the correct position before starting to avoid fuel injection. During operation, the oil level rises slightly, which is a normal phenomenon. When the fuel is insufficient, l vacuum pump oil is added from the fuel hole. Oil needs to be filtered to prevent debris from entering and plugging oil holes.

2. If the rotary vane vacuum pump mouth is equipped with an electromagnetic valve, it should act with the pump simultaneously.

3, rotary vane vacuum pump is started, should be to move the start button one or two times, so that the hydraulic pump chamber to the fuel tank, and then officially start operation.

4, the environment of high temperature, oil temperature increased, the viscosity decreased, the saturated steam increases, the vacuum will cause the limit down, ventilation should be strengthened.

5. Check the limit vacuum of the pump. The compression mercury vacuum gauge should be adopted. The vacuum gauge should be directly connected to the pump port and will reach the limit vacuum within 30 minutes.

Please turn off the valve at the inlet of 6, rotary vane vacuum pump before the pump stops, and isolated from the vacuum system, then stop the pump.

7.If the pump with gas valve is contained more condensable steam in the suction gas, the gas valve should be opened.

If you want to know more about our vacuum pump products, or if you want to consult rotary vane vacuum pump, please leave a message or send an email to contact@evpvacuum.com.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)