Dry Vacuum Pump Supply

Screw vacuum pump is a high-tech product developed by our company. It is mainly composed of screw rotor, shell, gear, cooling cycle and seal. The rotating shaft connects to the active rotor and rotates the rotor through a high-precision synchronous gear. The synchronous gear and bearing are lubricated with oil, and the bearing and housing are sealed internally by a seal to achieve an oil-free effect. A pair of rotating screw rod supported by the bearing of the two end caps of the pump in the opposite direction will be sucked into the air through three processes of gas inhalation, compression and exhaust to achieve the purpose of pumping.

Dry vacuum pump influence

Dry vacuum pump through constant development, in view of the influence of domestic vacuum industry is relatively large, after many years of production and development capacity, many enterprises in the continuous improvement of traditional equipment optimization, promote the high standard requirement of products, and increased the push for the entire performance advantages, in order to further enhance the product the effective development of practical ability, overall extended effectively ability, enhance the application effect of all aspects of product development, with the development of more practical factors that influence on the entire device to have a comprehensive promotion.

Increased understanding of dry vacuum pump, from aspects and so on advanced technology can reflect its own characteristics, which fully reflects the application ability of dry pump, its overall performance expression for its all aspects of the application are effective to ascend, expanded the productivity development of the enterprise, enhance the effective improvement of the product performance, and the application of energy conservation and emissions reduction ability, more reflects the degree of the influence of dry pump, this played a promoting role in the development of equipment in the future, but also on the characteristics of further implement the product application ability.

Therefore, it is necessary to strengthen the continuous development of the dry vacuum pump, enhance the internal quality of its products, in order to fully expand the production promotion, strengthen its advanced development ability, so as to enhance the effect of various aspects of application performance.

Strengthen the quality inspection of screw vacuum pump

In strengthen screw vacuum pump product advantage, we need to expand the product use and performance advantage of the strength, make the products used to enhance the promotion of the role of performance advantages, constantly improve the product application effect on the performance of the power, further enhance its application performance of the play, quicken the development of the actual performance products and application advantages, thus have the application advantages of overall development, make equipment ability improve the ability of using the quality reliable, the advantage of comprehensively promoting level to enhance the use effect of enterprise development.

Reasonable to improve the practical value of the play, screw vacuum pump products quickly enhance its overall use of product performance, in order to improve the product value to improve its quality of power, enhance the capacity of product use and advantage of expressive, which fully reflects the product use effect of the development advantage, improve the performance of its value the overall development, realize the ability of using their products pioneering, let its enhancement enterprise productivity growth in the process of application, highlighting its quality and its role in performance advantages.

At the same time, it is necessary to enhance the overall drive of screw vacuum pump product quality, according to the application ability of the equipment to enhance the embodiment of its value strength, with the practical effect of reliable application and performance development, constantly reflect the application of the product and the expansion of the overall strength, so as to improve the overall improvement of the actual application effect of the product.

EVP is a manufacturer and supplier of vacuum pumps, vacuum systems and vacuum accessories.

Product parameters

| Model | Unit | LG50 | LG70 | LG100 | LG150 | LG200 | LG300 | LG350 | ||

| Suction Capacity | 50 Hz | m³/hr | 180 | 250 | 360 | 540 | 720 | 1080 | 1260 | |

| 60 Hz | 216 | 300 | 430 | 650 | 850 | 1296 | 1512 | |||

| Ultimate Pressure | 50 Hz | mbar | 0.02 | |||||||

| 60 Hz | 0.01 | |||||||||

| Motor power | 50 Hz | Kw | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | |

| 60 Hz | 7.5 | 11 | 15 | 15 | 22 | 26 | 26 | |||

| Rotary Speed | 50 Hz | RPM | 2900 | |||||||

| 60 Hz | 3550 | |||||||||

| Inlet diam | mm | 50 | 65 | 70 | 90 | 100 | 100 | 100 | ||

| Outlet diam | mm | 40 | 40 | 55 | 65 | 65 | 65 | 65 | ||

| Lubricating oil consumption | L | 0.85 | 0.85 | 1.4 | 2 | 2 | 2 | 2 | ||

| Cooling water consumption | L/min | 2.5 | 2.6 | 2.8 | 3 | 4 | 4 | 4 | ||

| gal/min | 0.67 | 0.7 | 0.75 | 0.8 | 1.07 | 1.07 | 1.07 | |||

| Weight | Kg | 295 | 350 | 480 | 520 | 680 | 850 | 850 | ||

| Noise | dB(A) | 68 | 70 | 70 | 72 | 74 | 84 | 84 | ||

| Working temperature | ℃ | 5~40 | ||||||||

| Max. Permissible humidity | / | 90% | ||||||||

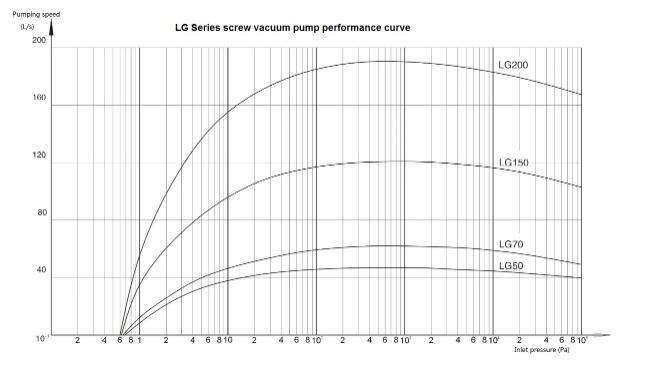

Performance curve

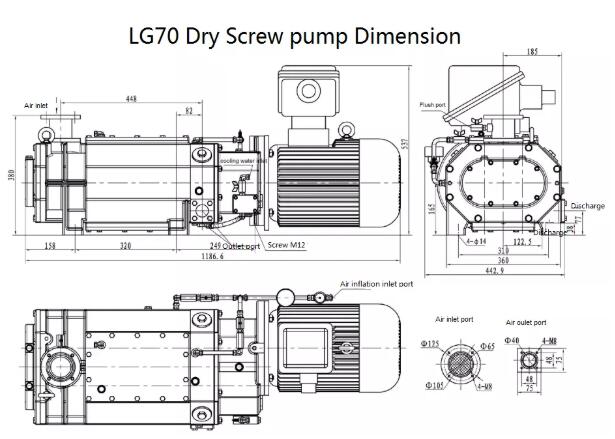

Installation dimensions

Related video

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)