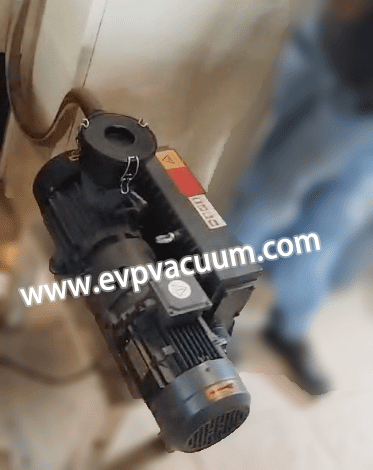

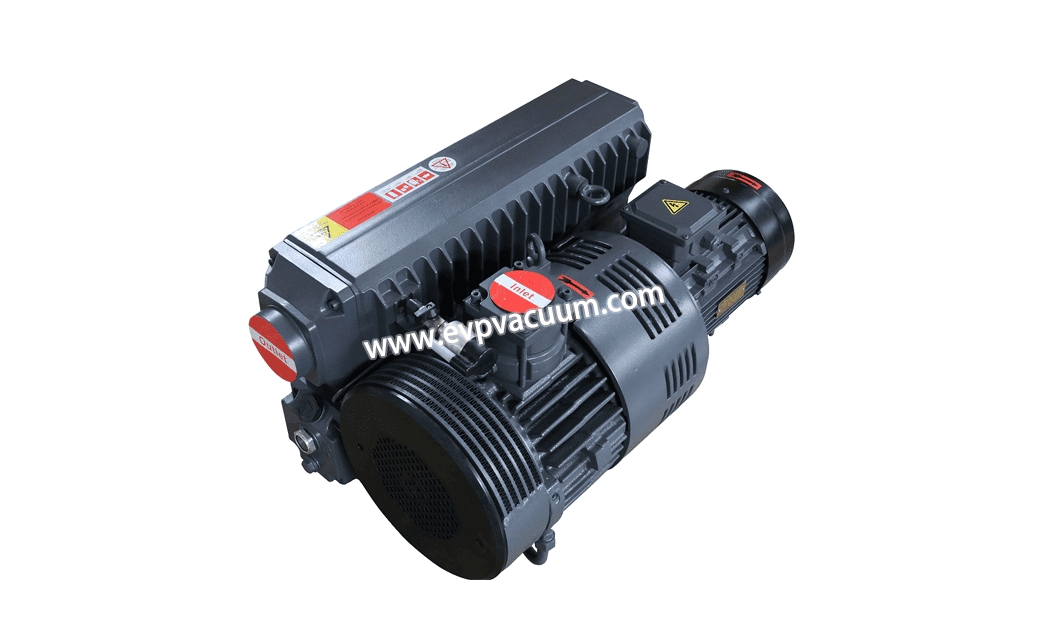

rotary vane vacuum pump in Soap Production Process

SV series rotary vane vacuum pump in Soap Production Process of Application

In the soap production industry, innovative technologies continue to revolutionize manufacturing processes, with the latest advancement being the application of SV series rotary vane vacuum pumps. These pumps have proven to be highly effective in various industries due to their gentle product handling, low shear, and efficient performance. Recently, soap manufacturing company has incorporated rotary vane vacuum pumps into their production process, leading to improved efficiency and product quality.

The SV series rotary vane vacuum pump, known for its positive displacement and gentle pumping action, is ideal for handling viscous and sensitive fluids such as soap ingredients. By precisely controlling the flow rate and pressure, these pumps ensure consistent and homogenous mixing of raw materials, resulting in high-quality soap products with uniform properties.

One of the key benefits of using the SV rotary vane vacuum pump in soap production is its ability to improve the overall production efficiency. By accelerating the evacuation process and reducing the time required for degassing, the pump helps increase the production yield while maintaining product consistency.

The SV rotary vane vacuum pump is characterized by its low noise operation and minimal maintenance requirements, making it a cost-effective and sustainable solution for soap manufacturers.

Moreover, the sanitary design of SV series rotary vane vacuum pump allows for easy cleaning and maintenance, meeting the strict hygiene requirements of the soap production industry. The pumps’ robust construction and corrosion-resistant materials ensure long-term reliability and durability, contributing to uninterrupted production processes and reduced downtime.

The application of SV series rotary vane vacuum pumps in the soap production process has not only optimized operational efficiency but also enhanced product consistency and quality. The precise metering capabilities of these pumps enable accurate dosing of ingredients, reducing waste and maximizing resource utilization. Overall, the adoption of rotary lobe pumps in soap manufacturing represents a significant technological advancement that benefits both producers and consumers alike.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)