Rotary vane vacuum pump operation

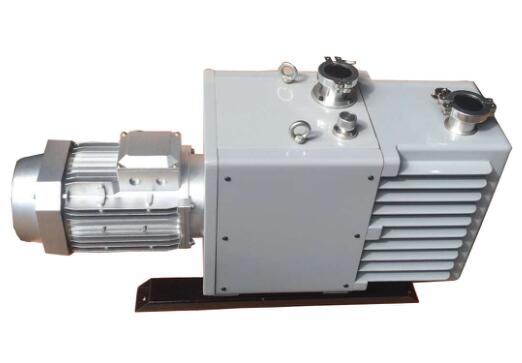

Rotary vane vacuum pump is a two-stage direct connection structure. Its working performance consists of two parts: high-pressure stage and low-pressure stage. Its suction port is connected with vacuum equipment. During operation, a large number of gases in the container are sucked and discharged. When the equipment is vacuum, the high-pressure exhaust valve is closed, and the gas in the high-pressure stage entrance will be transferred to the second stage. By the second stage suction and discharge vacuum equipment, a certain vacuum can be obtained. The technical parameters of the rotary vane vacuum pump are 6*10-2 Pa. The pump is connected with the motor shaft, with high speed, small appearance, compact structure and convenient fluidity. It can be used in the manufacture of electric vacuum devices, the manufacture of vacuum flasks, vacuum welding, printing, plastic absorption and refrigeration. Equipment repair and instrumentation matching. Because it has the advantages of small size, light weight and low voice, it is more suitable for use in laboratories.

2XZ Direct Drive Rotary Vane Vacuum Pump

Rotary vane vacuum pump working principle

The rotary vane vacuum pump is a two stage high speed direct connection rotary vane vacuum pump. It has eccentric rotors installed in the pump cavity and rotary vane inside the rotor groove. When the rotor drives the blade to rotate, the blade is close to the wall of the chamber, separating the inlet and exhaust ports, and expanding the volume of the intake cavity periodically, while the volume of the exhaust cavity shrinks periodically and compresses the gas, pushing the exhaust valve to exhaust, thus obtaining vacuum.

Rotary vane vacuum pump characteristics

Rotary vane vacuum pump has the advantages of small volume, light weight, low noise and easy starting. In addition, there are measures to prevent oil return and no measures to prevent oil seal from polluting the site.

1. Rotary vane vacuum pump is the basic equipment to obtain vacuum. It can act independently, and can also be used as the front pump and pre-pump of various high vacuum systems to form Roots vane vacuum unit.

2. The air inlet of the rotary vane vacuum pump is continuously open to the atmosphere and can not run for more than three minutes.

3. Pumps are not suitable for extracting gases containing particulate dust, which are corrosive to metals and react chemically with pump oil, in order to contain excessive oxygen and explosive gases.

4, pump can be used as compression pump or delivery pump.

5. Working environment of rotary vane vacuum pump: in the temperature range of 5-40 C, the relative temperature is not more than 90%, and the inlet pressure is less than 1333 3a, which allows long-term continuous operation.

6. When installing and connecting the power supply, according to the stipulation of the motor label, the rotation direction of the motor should be in accordance with the arrow direction on the support.

7. The diameter of the pipeline of the continuously pumped container should be no less than the diameter of the intake port of the pump, and the pipeline should be short and less elbows, while paying attention to the leakage of the pipeline.

8, every time before starting to focus on oil level, to stop pump oil to oil glass diameter 4/5 height.

9. Rotary vane vacuum pump can start at once in the atmosphere or under any vacuum. If the single stage swirl type is really difficult to start, the intake pipe plug cap can be switched off and then put into operation.

Rotary vane vacuum pump maintenance

1. ensure that the rotary vane vacuum pump is clean and prevent debris from entering the rotary vane vacuum pump.

2. keep the oil level.

3. Pay attention to the cleanliness of the oil. If the pump oil becomes dirty, turbid, water or other volatile substances enter the 2XZ rotary vane vacuum pump and affect the limit vacuum, the air ballast valve can be opened to purify it, and the limit vacuum recovery can be observed for hours. The pump oil should be replaced, and if necessary, it can be replaced again. Oil change method: the pump runs for about half an hour, thinning the oil, stopping the pump to drain the oil from the drain hole, then opening the intake port to run for 10-20 seconds. A small amount of clean pump oil can be slowly added from the suction port to replace the oil in the pump chamber. If the oil is dirty, the latter can be repeated.

4. do not mix diesel and gasoline with other saturated vapor pressure to avoid extreme vacuum. When the components in the rotary vane vacuum pump are disassembled and cleaned, it is generally possible to wipe them with gauze. When metal debris, sand mud or other harmful substances must be cleaned, they can be scrubbed with gasoline, and then assembled after drying. Never soak in gasoline.