rotary vane vacuum pump working principle

The standard lubrication rotary vane vacuum pump is a single-stage pump with an integrated closed-loop oil circulation system. The structure is strong and durable. The typical blade life is 50000 hours.

Rotary vane vacuum pump is a kind of oil sealed mechanical vacuum pump. Its working pressure range is 101325 ~ 1.33 × 10-2 (PA), which belongs to low vacuum pump. It can be used alone or as the front pump of other high vacuum pump or ultra-high vacuum pump. It has been widely used in metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, medicine and other production and scientific research departments.

The rotary vane vacuum pump can pump out the dry gas in the sealed container, and can pump out a certain amount of condensable gas if equipped with gas ballast device. But it is not suitable for pumping out gases with high oxygen content, corrosive to metal, chemical reaction to pump oil and containing particulate dust.

Rotary vane vacuum pump is one of the most basic vacuum equipment in vacuum technology. Rotary vane vacuum pumps are mostly small and medium-sized pumps. There are two kinds of rotary vane vacuum pumps: single-stage rotary vane vacuum pump and double-stage rotary vane vacuum pump. The so-called two-stage, is in the structure of the two single-stage pump in series. Generally, it is made into two-stage to obtain higher vacuum.

The relationship between pumping speed and inlet pressure of rotary vane vacuum pump is as follows: when the inlet pressure is 1333pa, 1.33pa and 1.33 × 10-1 (PA), the pumping speed shall not be lower than 95%, 50% and 20% of the nominal pumping speed of the pump respectively.

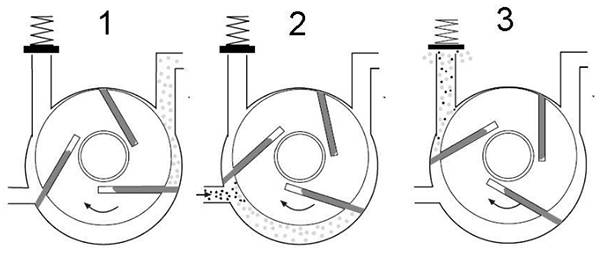

Rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover and spring. A rotor is eccentrically installed in the cavity of the vane pump. The outer circle of the rotor is tangent to the surface of the cavity (there is a small gap between the two). Two rotors with springs are installed in the rotor slot. When rotating, the centrifugal force and spring tension make the top of the vane keep in contact with the inner wall of the pump cavity, and the rotation of the rotor drives the vane to slide along the inner wall of the pump cavity.

When the two parts of a and C are in the direction of the arrow, the volume of a and C is gradually increased. The volume of the space C connected with the exhaust port is gradually reduced and is in the process of exhaust. The volume of space B in the middle is also gradually decreasing, which is in the process of compression. Because the volume of space a is gradually increasing (that is, expanding), the gas pressure decreases, and the external gas pressure at the inlet of the pump is greater than the pressure in space a, so the gas is inhaled. When space a is isolated from the suction port, that is, it turns to the position of space B, the gas begins to be compressed, the volume gradually shrinks, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas is discharged into the atmosphere through the oil layer in the oil tank. The purpose of continuous pumping is achieved by continuous pumping. If the discharged gas is transferred to another stage (low vacuum stage) through the air passage, it is pumped away by the low vacuum stage, and then compressed by the low vacuum stage and discharged into the atmosphere, which forms a two-stage pump. At this time, the total compression ratio is borne by two stages, so the ultimate vacuum degree is increased.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)