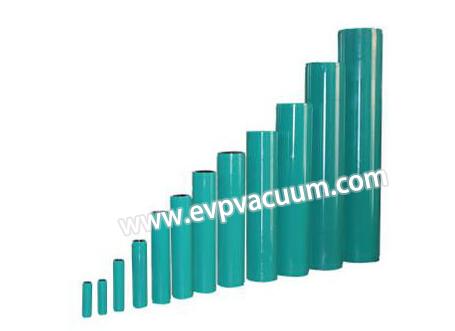

Screw pump stator

The stator of screw vacuum pump is an important part easy to be damaged in screw pump. The accuracy of stator tooth profile curve and material selection must be considered in the design and development, which directly determines the length of stator life.

The selection of rubber material formula must take into account what kind of medium (medium composition and corrosivity of medium, etc.) and medium temperature, as well as rubber hardness, expansion rate and tensile strength of rubber in medium. The performance of rubber after pressure injection can not only determine the life of the stator, but also affect the normal operation of the pump. For example, NBR must be selected to transport oil medium, because many rubber is not resistant to oil medium; fluororubber should be selected for high temperature medium.

Hardness is a very important index of the performance of the stator rubber: it is expressed by the degree of resistance of the elastic surface under the vertical quantitative load. Shore hardness (a) is the most commonly used in China (GB / T 531-1983).

Screw vacuum pump stator of wear mode

Many people may not be familiar with the stator of the screw vacuum pump. It is made of rubber and the rotor is made of steel, which determines the failure mode of the screw pump. Therefore, it is very important to introduce the wear mode of the screw vacuum pump. Here we will introduce the wear mode of the stator of the vacuum pump

1、 Erosion wear:

This is caused by the fluid flow between the rotor and stator of the screw pump, which is also called erosion wear. Under the normal working conditions of the screw pump, it is also one of the main forms of wear.

2、 Abrasive wear

1) This is due to the contact between the sharp edges of the abrasive particles or the hard protruding parts on the rough surface of the screw, and the unevenness of the rotor rubber surface and the existence of mechanical impurities in the extracted liquid.

2) The so-called wet abrasive wear is that there is a liquid medium between the abrasive particles and rubber, and the dry abrasive wear is that there is no liquid medium between the abrasive particles and rubber.

3、 Friction and wear:

1) Only when the friction coefficient is large and the tear strength of rubber is very low, when dry friction, the friction between the rotor and stator is heated, which makes the rubber temperature rise and reduces the rubber tear strength.

2) When this kind of wear occurs, the rubber surface is torn, curled and stretched, and falls off from the rubber surface, and the surface resin is aged and sticky, so that the rubber will aggravate the friction and wear, and the stator will be damaged rapidly.

4、 Fatigue wear:

1) The friction force and contact stress between the stator rubber and the blunt dual surface on the rotor are not too large.

2) Because this kind of wear is similar to abrasive wear in many aspects, some scholars regard it as a form of abrasive wear. Compared with abrasive wear, it is a kind of low strength wear, namely round blunt abrasive wear.

The four forms of stator wear of screw vacuum pump often occur at the same time, but in different working conditions, the main form of wear is certain. Therefore, the reasonable design of the manufacturer will reduce the wear rate of stator to a very low level, thus realizing the extension of equipment life.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)