Screw vacuum pump selection

Screw vacuum pump used to pump sludge and other media containing solid particles, screw pump pressure is relatively large, generally can reach 0.6mpa – 1.2mpa.

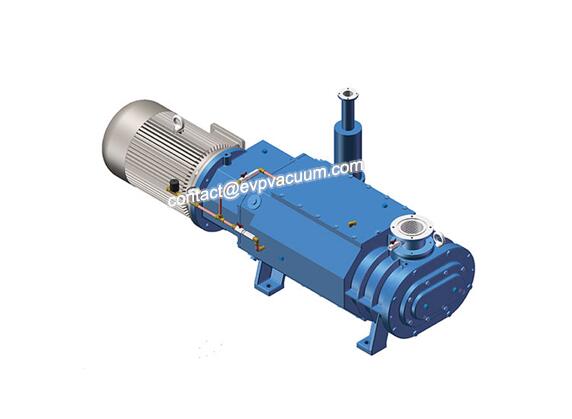

Screw vacuum pump is a kind of method of eccentric rotary positive displacement pump, the pump of the main components: a single head screw rotor and a usually made of elastic material has a pun spiral stator, when the rotor is scheduled to give a planet revolving round the axis of the stator inside the cavity, airtight wrist is formed between the stator along the spiral rotor displacement; Therefore, the medium continuous, uniform speed, and volume constant from the suction to the pressure out of the end, based on this characteristic, good kaide screw pump is particularly suitable for the following conditions of work.

Screw pump transport medium of high viscosity: according to the size of the pump can transport viscosity from 37000 to 200,000 MPA medium.

Medium containing particles or fibers: particle diameter may be 30mm (not exceeding rotor eccentricity). The length of the fiber can be 350mm (equivalent to the pitch of the 0.4 bit rotor). Its content generally can reach 40% of the medium cellar, if the solid in the medium is fine powdery, the highest content can reach 60% or more can also be transported. Requirements of stable transmission pressure, the inherent structure of the medium is not damaged, the choice of kaide screw pump transmission is the most ideal.

Screw vacuum pump because of its variable transport, self-absorption ability, can be reversed, can transport liquid containing solid particles and other characteristics, in the sewage treatment plant, is widely used in the transport of water, wet sludge and flocculant liquid. Screw pump selection should follow the principle of economy, rationality and reliability. If not considered in the design and selection, will bring trouble to the future use, management, maintenance, so choose a according to the actual production needs, reasonable and reliable screw pump can not only ensure the smooth production, but also reduce the repair cost. Now in the application of good kaide screw pump speed selection of some experience as follows:

Screw vacuum pump speed selection:

A linear relationship with screw pump flow rate and rotational speed, low relative to the rotating speed of screw pump, high rotational speed of screw pump, can increase the flow and head but power obviously increase, high speed accelerate the abrasion between the rotor and stator, must make the premature failure of screw pump, and the high speed of the screw pump stator length is short, easy to wear and tear, thus shortening the service life of the screw pump.

Through the speed reduction mechanism or stepless speed regulation mechanism to reduce the speed, so that its speed is kept in a more reasonable range of 300 revolutions per minute, compared with the high-speed operation of the screw pump, the service life can be extended several times.

Screw vacuum pump selection of key points

Long time stop the screw vacuum pump in the launch has been required to roll a number of turns by hand, to prove that there is no stuck or other damage scene inside the pump. At the moment, the need to open the exhaust valve, start the motor, but pay attention to the motor’s positive rotation, then gradually add water supply, water supply to comply with the rules begged to stop, at the moment should pay attention to do not dry task vacuum pump.

With the rapid development of China’s economy and the increasing demand for environmental protection, the pump industry, as the “heart of industry”, has made great progress. Especially intensive policy support, environmental protection equipment manufacturing leap forward, dry pump industry has not developed space is considerable.

Although the screw vacuum pump has so many advantages, however, because some companies are currently using the screw vacuum pump is imported from abroad, the price is very expensive, the price of each screw pump to three, four hundred thousand yuan, so the screw vacuum pump in our country is not widely used. The main reason for this phenomenon is that the screw pump rotor line is more complex, processing difficulty, with special tools in special machine tools for processing. In addition, the processing accuracy of the screw vacuum pump body also has higher requirements, and the domestic processing level is difficult to achieve this level. Old-fashioned water ring vacuum pumps have been unable to meet the requirements of corrosion and environmental protection, a lot of oil-free vacuum pump and the corrosion resistance of vacuum pump slowly replaced the old vacuum pump, water ring vacuum pump is through strict test, the continuous development of especially close attention to environmental protection, environmental protection consciousness enhancement, many enterprises have enhanced awareness of the new equipment. In China, there are basically a certain scale of vacuum pump manufacturers, have entered the field of research and development of screw vacuum pump, because of the urgent demand of market economy, for manufacturers, do not develop new products will be eliminated by the market. Screw vacuum pump industry present situation, market demand more and more obvious in recent years, screw vacuum pump vacuum industry has been linked to the development of industry of the intimate relationship, if this is environmental protection, simple structure, long use time, do not produce any pollution, the screw vacuum pump will be a revolutionary change.

In order to promote the development of the dry vacuum pump, the effect of practical application, to enhance their products with the growing strength of the application ability, strengthening the overall expansion of product effectively, driven by the product strength, to improve their ability of application based on the perfect product development, expand the use performance actually fully manifests, in all aspects of advantage of dry pump application abilities, to further the implementation of the whole application situation, thus more manifests the advantages, the application effect of the development of more reflect the product development capability. Reasonable use of dry vacuum pump overall value ability performance strength, according to its overall use and performance development of rational promotion, expand the practical performance of all aspects, promote the overall improvement of the application effect of its product strength, further accelerate the development of its product use advantage. The screw vacuum pump is equipped with a biased rotor with fixed blade, which throws water to the stator wall, and the water constitutes a concentric liquid ring with the stator, and the liquid ring and the rotor blade constitute a rotary displacement vacuum pump with variable volume. So what is the process of screw vacuum pump initiation and shutdown? Now, let’s understand it in detail.

Selection method: in order to facilitate you to correctly choose the type of dry vacuum unit, please provide the following details:

The operating environment and operating conditions of the unit, such as the composition of gas extraction, temperature, whether condensation recovery or filtration is required.

From the advanced technology and other aspects can reflect its own characteristics, fully reflects the dry pump application ability, its overall performance of the performance of all aspects of its application have been effectively improved, expanded the productivity of the enterprise, enhance the effective improvement of the performance of each product. Increase the understanding of dry vacuum pump and the application ability of energy saving and emission reduction, more reflect the influence of dry pump, which promotes the development of equipment in the future, and further realize the ability of product application in terms of characteristics.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)