Selection of vacuum pump for electron beam welding machine

Electron beam welding machine vacuum pump selection, supply vacuum electron beam welding machine, vacuum pump, electron beam welding in configuration of the vacuum pump vacuum environment because of have no electrode, it is not easy oxidation, process repeatability and the advantages of small thermal deformation and is widely used in aerospace, nuclear, national defense and military industry, automobile and electrical electrician instrumentation, and many other industries. Electron beam welding requires a high vacuum degree, usually need to configure more than one vacuum pump can meet the requirements, vacuum pump is a compact structure, strong and durable, safe environmental protection of the vacuum pump, rotor with good geometrical symmetry, small vibration, stable running, high vacuum pump, so much as the backing pump of vacuum electron beam welding machine configuration.

Our technicians have many years of industry application experience, draw lessons from the advantages of a number of European and American products, combined with the use and maintenance habits of Chinese users and independently developed products.

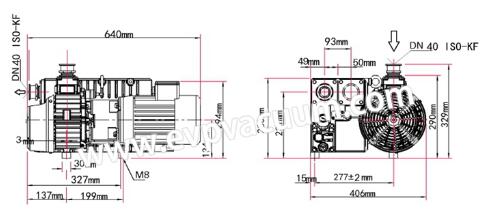

Size:

Vacuum pump parameters

Pumping rate: 300 m3 / h

Ultimate pressure: 0.1mbar

Power source: 380 v

Motor power: 7.5KW

Weight: about 210KG

Can be configured according to the application requirements of a variety of accessories, compact volume, quiet operation, especially suitable for all kinds of machinery and equipment.

Electronic beam welder vacuum pump selection product features:

1. Precise design, strong structure, light weight, easy to install and maintain.

2. Low noise, low vibration, the working environment will not be affected

3. Built-in high efficiency oil mist filter, the discharged gas does not contain oil mist

4. Adopt wind cooling, but the larger vacuum pump is equipped with cooling air duct. Use fan to cool the lubricating oil in the duct to improve the cooling effect

5. Built-in check valve and air ballast valve can avoid oil reverse flow caused by pump reversal after shutdown and avoid condensing into water point through compression under high vacuum environment, which will cause lubricating oil emulsification and deterioration

6. Strong suction volume, maximum vacuum up to 0.1mbar(10Pa)

7. Run quietly.

Electron beam welding machine type vacuum pump, vacuum pump has been widely applied in all kinds of instruments and vacuum packaging, vacuum suction molding rubber and plastic industry, printing industry in the paper, all kinds of casting of vacuum impregnation leakproof, vacuum clamp on mechanical processing, electronic components vacuum clamp positioning on the semiconductor industry, chemical industry on the vacuum drying, filtration, large mechanical parts in the empty the true state of dynamic balance test and the vacuum extraction of hospital operating rooms in this type of pump can achieve the vacuum range of all kinds of vacuum treatment.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)