SK series water ring vacuum pump and compressor

SK series water ring vacuum pump and compressor application and scope:

SK series water ring vacuum pump is used to pump or press gas and other non corrosive, water-insoluble and solid particles free gas, so as to form vacuum or pressure in a closed container, so as to meet the requirements of specific process flow. A small amount of liquid is allowed in the gas inhaled or compressed.

SK series water ring vacuum pumps and compressors are widely used in machinery, petroleum, chemical, pharmaceutical, food, ceramics, sugar manufacturing, printing and dyeing, metallurgy, environmental protection and electronics industries.

In the working process, water ring vacuum pump compresses the gas in the isothermal state, so it is not easy to cause danger when it compresses or sucks flammable and explosive gas, so it is more widely used.

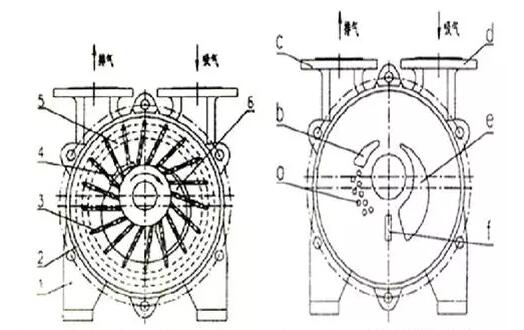

SK series water ring vacuum pump working principle:

As shown in the figure, impeller 3 is installed eccentrically in pump body 2, and water of a certain height is injected into the pump as working fluid when starting. When impeller 3 rotates in the direction shown in the figure, water forms a rotating closed water ring 5 on the inner wall of the pump body under the action of centrifugal force. The inner surface of the upper part of the water ring is tangent to the hub, and the inner surface of the lower part of the water ring just contacts the top of the blade. At this time, a crescent space is formed between the impeller hub and the water ring, and this space is divided into several small cavities equal to the number of blades by the impeller. If the upper 0 ° of the impeller is taken as the starting point, the volume of the small cavity will increase from small to large when the impeller is 180 ° before rotation, and the small cavity is connected with the suction port on the end cover, the gas pressure in the space will decrease, at this time, the gas will be inhaled, and the small cavity will be isolated from the suction port when the suction is finished; when the impeller is 180 ° to 360 ° during rotation, the inner surface of the water ring will gradually close to the hub, and the small cavity will change from large to small When the pressure of the gas in the space is higher than that of the exhaust port, when the small chamber is connected with the exhaust port, the gas is discharged. Every time the impeller rotates once, the space between the blades (small cavity) sucks and exhausts once, and several small cavities work continuously. In this way, the pump continuously sucks or compresses the gas.

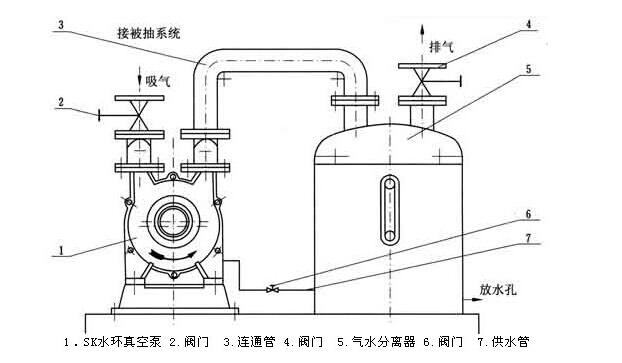

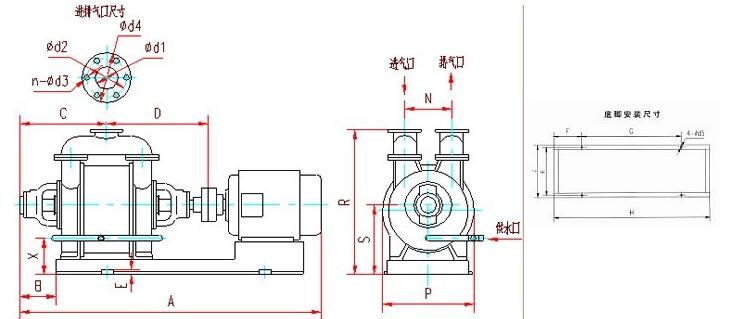

SK type water ring vacuum pump Installation dimension drawing :

Before the installation of SK type water ring vacuum pump, first rotate the coupling with water to confirm whether SK type water ring vacuum pump is stuck or damaged. When the whole set of equipment arrives at the installation site, the package has been damaged or damped during storage, and SK type water ring vacuum pump is installed and used eight months after leaving the factory, it shall be completely disassembled for inspection and repair before installation. If the vacuum pump or compressor operates normally, install SK type water ring vacuum pump on the pump base. Before the motor is fixed on the pump base, the concentricity of the motor shaft and the pump shaft shall be corrected, because even the slight inclination of the motor shaft and the pump shaft will cause the bearing heating and the parts wear. If the straight edge is placed on the coupling in parallel, there is no gap between the whole circumference and the circumference of the coupling, and the axial gap of the coupling is equal, the required concentricity of SK type water ring vacuum pump is achieved (as shown in the figure).

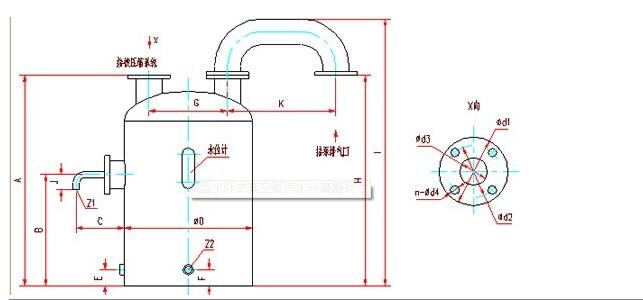

Installation dimension drawing of SK type water ring vacuum pump steam water separator:

1. The gas water separator is installed on the foundation according to the outline drawing.

2. If it is necessary to change the installation position, it shall be noted that the connecting pipeline between the separator and the pump shall not be too long and the turning shall not be too fast, otherwise the flow loss of the gas-water mixture in the pipeline will increase, which will increase the exhaust resistance, reduce the flow and vacuum degree, and increase the power consumption.

3. The air inlet flange of the air-water separator is connected with the exhaust flange of the pump by an elbow.